Dustproof heat dissipation type reversing camera

A camera and heat-dissipating technology, which is applied in the field of dust-proof and heat-dissipating reversing cameras. It can solve the problem that the reversing camera is easily covered by dust and the temperature, so as to achieve a good heat dissipation effect and delay the time of dust clogging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

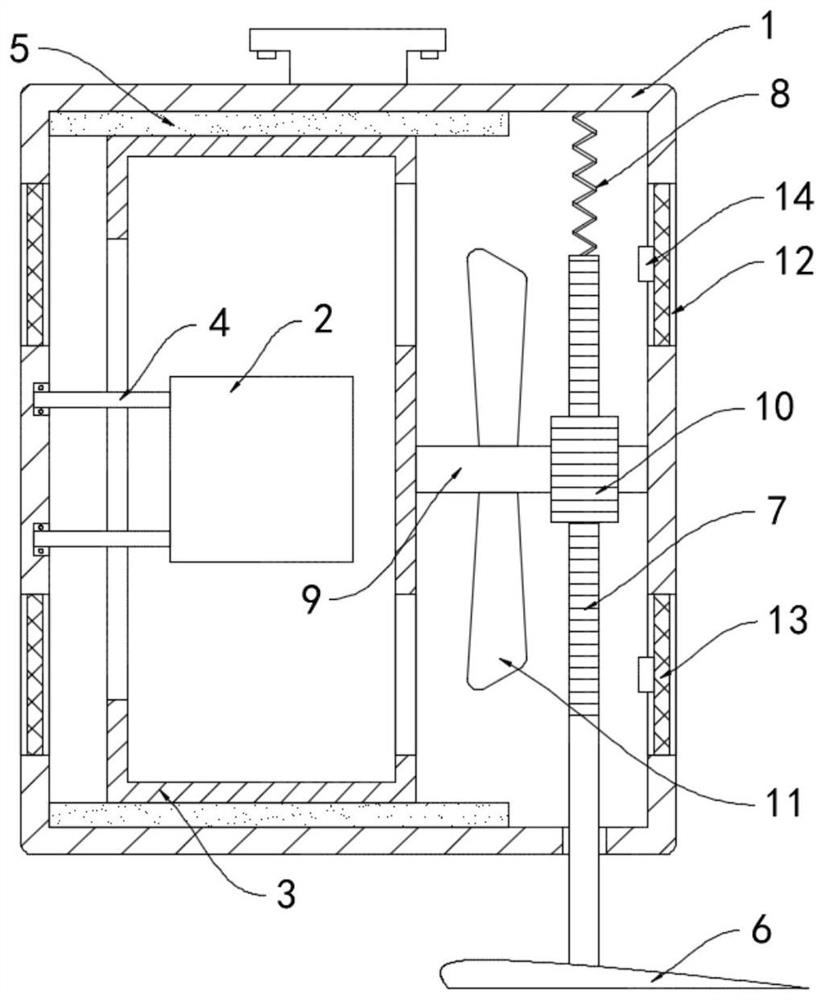

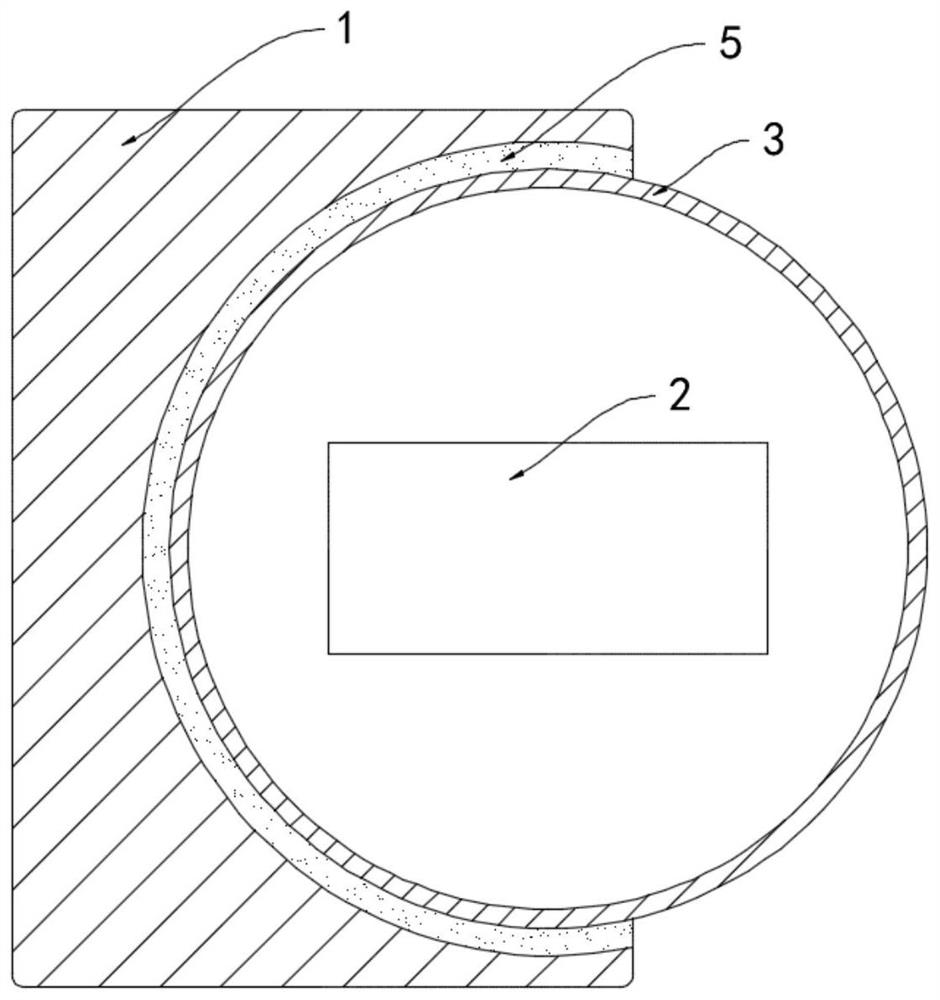

[0021] Such as Figure 1-2 As shown, a dust-proof and heat-dissipating reversing camera includes a housing 1 and a camera 2 fixedly installed at the bottom of the vehicle. A protective cover 3 is rotatably connected to the housing 1. The protective cover 3 is a transparent glass cover, and the protective cover 3 is a tube. The front end of the protective cover 3 extends out of the housing 1, and the camera 2 is installed in the protective cover 3. The camera 2 is rotationally connected with the inner side wall of the housing 1 through the connecting rod 4, and the inner side wall of the housing 1 is fixedly connected with a sticker Combine the dust removal brush 5 that protective cover 3 surface is provided with.

[0022] The bottom of the housing 1 is provided with a horizontally arranged wing plate 6, the upper surface of the wing plate 6 is in the shape of an upwardly convex arc, and the lower surface is in a horizontal line. The upper end of the wing plate 6 is fixedly con...

Embodiment 2

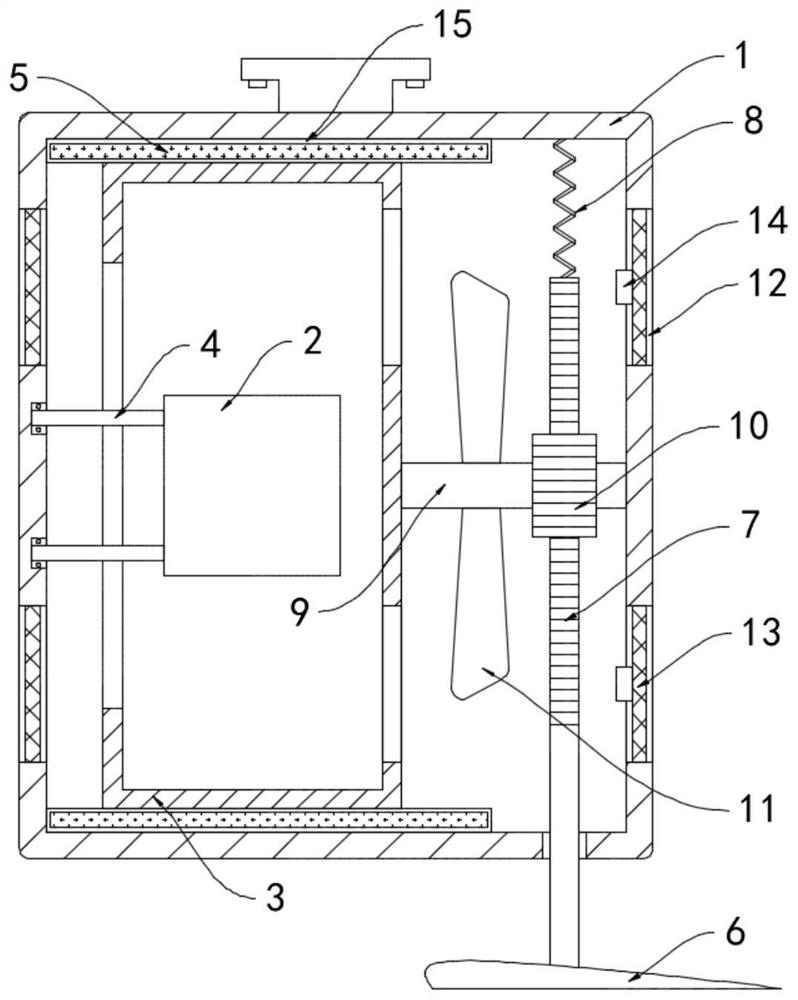

[0028] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the dust removal brush 5 includes a transparent liquid bag 15 fixedly connected to the inner side wall of the housing 1, and bristles are embedded on the side wall of the transparent liquid bag 15 close to the protective cover 3 , the transparent liquid capsule 15 is filled with flowing liquid mixed with magnetic powder.

[0029] In this embodiment, in the natural state, the magnetic powder in the transparent liquid capsule 15 is attracted to the side close to the wind wheel 11. After a long time of use, dust will inevitably enter the inside of the housing 1, and the dust will adhere to the surface of the wind wheel 11. As the accumulation of dust increases, the attraction force of the wind wheel 11 to the magnetic powder gradually decreases, and the magnetic powder is dispersed throughout the flow liquid. By observing the distribution of the internal magnetic powder through the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com