Pneumatic vehicle tire

A technology for pneumatic tires and vehicles, applied to vehicle parts, tire parts, tire tread/tread pattern, etc., can solve the problems of reducing the stiffness of tread ribs, rolling noise defects, etc., and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

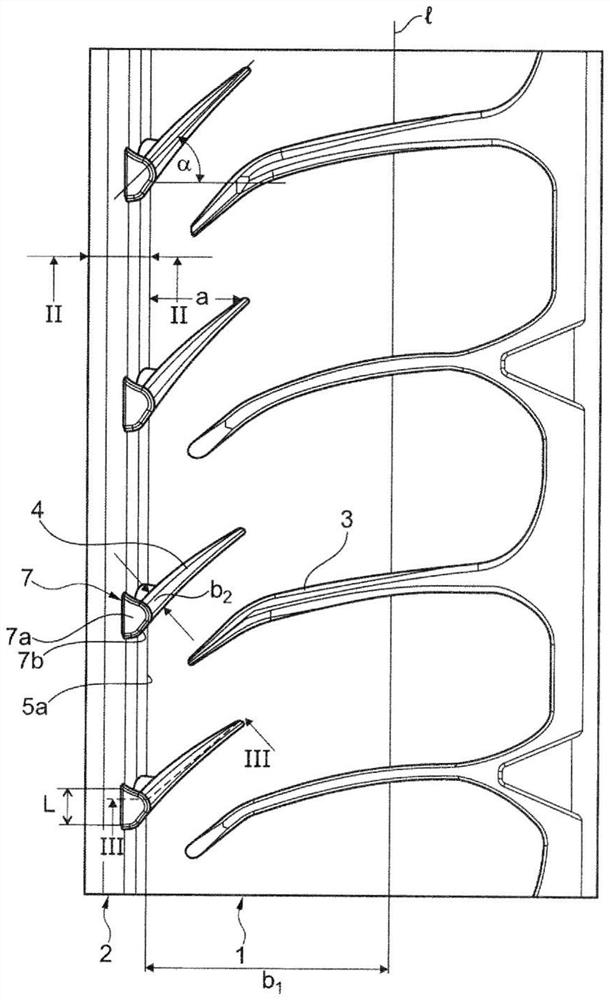

[0036] The vehicle pneumatic tire designed according to the invention is in particular a radial vehicle tire for passenger cars, vans and light trucks.

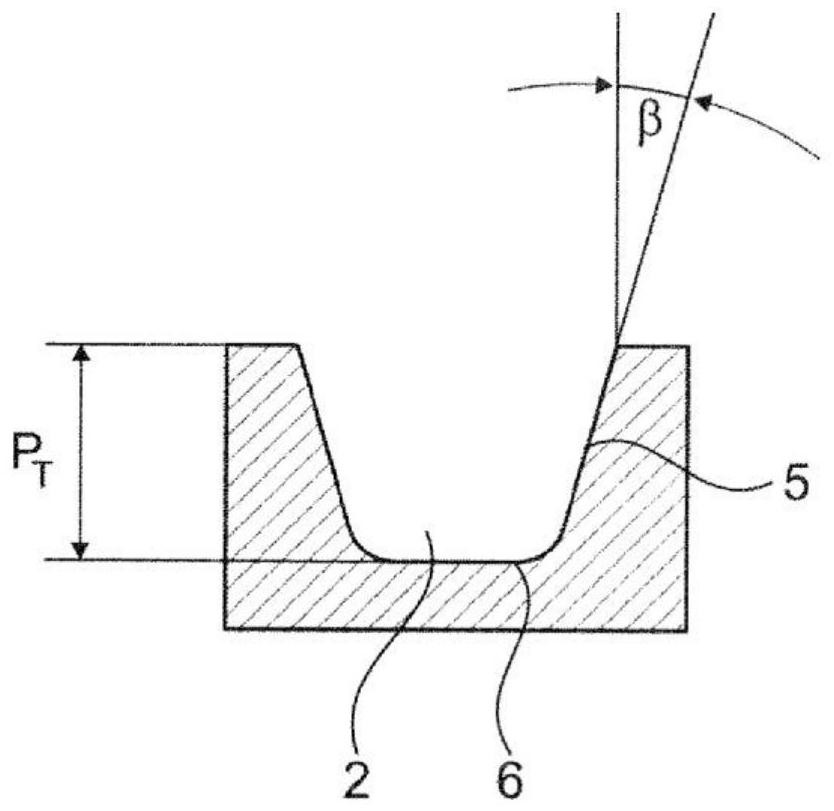

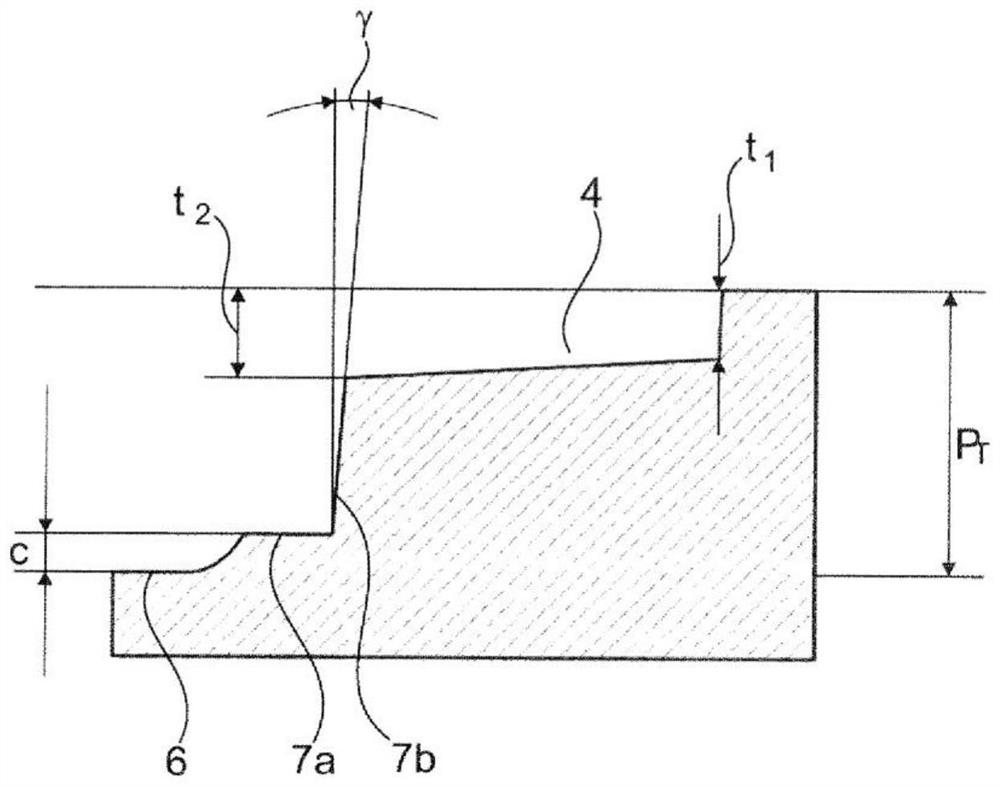

[0037] figure 1 Shown is a plan view (expanded in a plane) of the shoulder-side region of the tread having a shoulder-side rib 1 and circumferential grooves 2 delimiting said rib on the inner side of the tread, as figure 2 As shown in the cross-sectional illustration in , the circumferential groove has a depth P T , which corresponds to the tread depth provided for the corresponding tire. figure 1 The dashed line l in represents a lateral edge of the tire's ground-contacting surface. In the shown embodiment, the circumferential grooves 2 extend straight in the circumferential direction, but, like conventional circumferential grooves, they may also have a zigzag or wave shape. The patterned tread regions adjoining the circumferential grooves 2 on the tread inner side are not shown, and these patterned tread regions may fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com