Hybrid movable coil plate and flat-panel loudspeaker using the same

A moving coil and speaker technology, applied in the direction of sensors, circuit lead arrangement/elimination, magnetic objects, etc., can solve the problems of increased impedance, decreased mass production efficiency, large consumption, etc., to increase the induced electromotive force, realize impedance control, The effect of improving sound pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

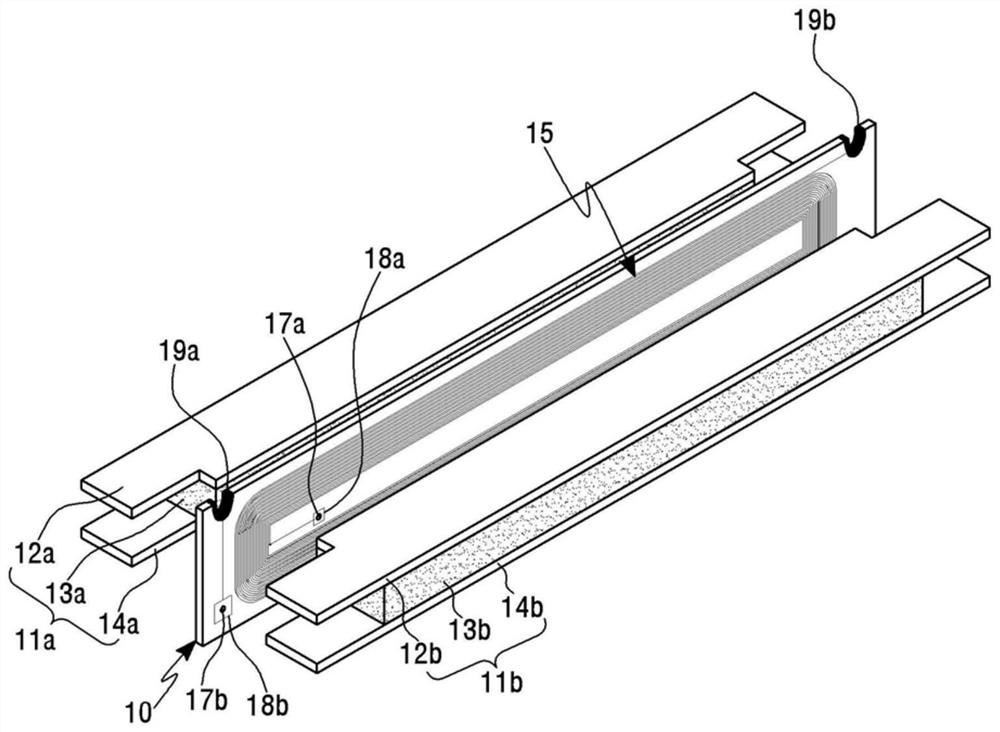

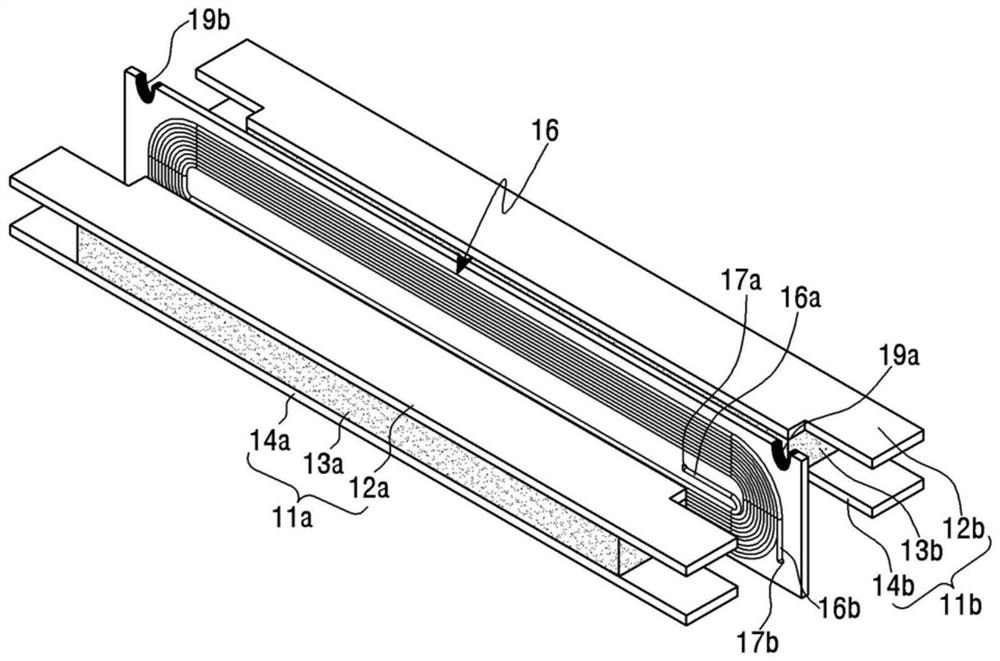

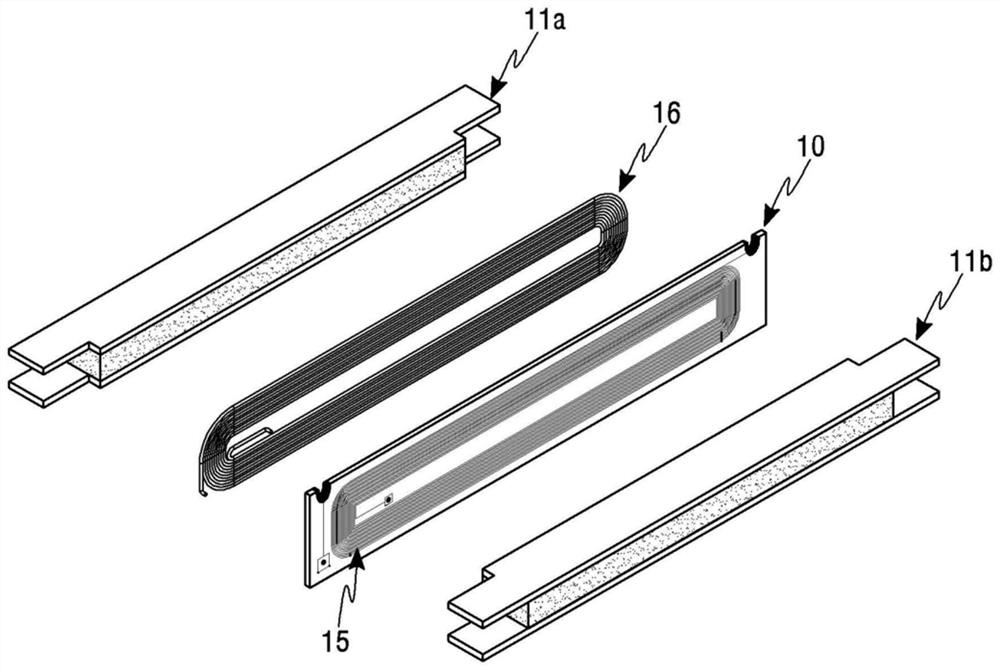

[0055] figure 1 It is a schematic perspective view of a flat-panel speaker including the hybrid movable coil plate according to the first embodiment of the present invention, figure 2 It is a schematic perspective view showing another angle of the flat-panel speaker including the hybrid movable coil plate according to the first embodiment of the present invention, image 3 It is an exploded perspective view of the copper wire coil of the flat-panel speaker including the hybrid movable coil plate of the first embodiment of the present invention, Figure 4 It is a sectional view of a flat-panel loudspeaker including the hybrid movable coil plate of the first embodiment of the present invention.

[0056] exist image 3 In order to facilitate the description and help understanding the arrangement relationship, only the copper wire coil 16 is disassembled and arranged on the side surface of the movable coil plate 10 , and the copper wire coil 16 is pasted on the side surface of ...

no. 2 example

[0075] Figure 5 It is a schematic perspective view of a flat-panel loudspeaker including a hybrid movable coil plate according to a second embodiment of the present invention, Image 6 It is an exploded perspective view of the copper wire coil of the flat-panel speaker including the hybrid movable coil plate of the second embodiment of the present invention, Figure 7 It is a cross-sectional view of a flat-panel loudspeaker including a hybrid movable coil plate according to a second embodiment of the present invention.

[0076] exist Image 6 In order to facilitate the description and help understanding the arrangement relationship, only the copper wire coil 26 is disassembled and arranged on the side surface of the first movable coil plate 20a, and the copper wire coil 26 is pasted on the side surface of the first movable coil plate 20a for use.

[0077] Comparing the second embodiment of the present invention with the first embodiment, it can be seen that the number of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com