A hinge intelligent assembly device with automatic orientation and its orientation method

A technology for assembling equipment and hinges, applied in the direction of metal chains, etc., can solve the problems of cumbersome assembly process, low production efficiency, inability to attach rivets, etc., to shorten the production cycle, facilitate production and use, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

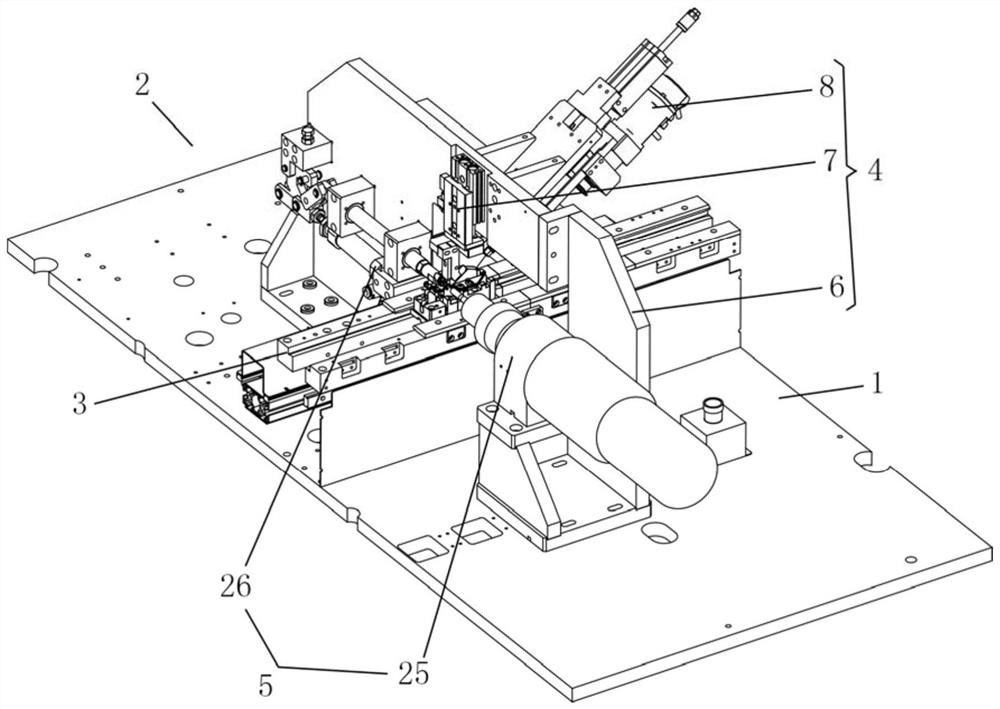

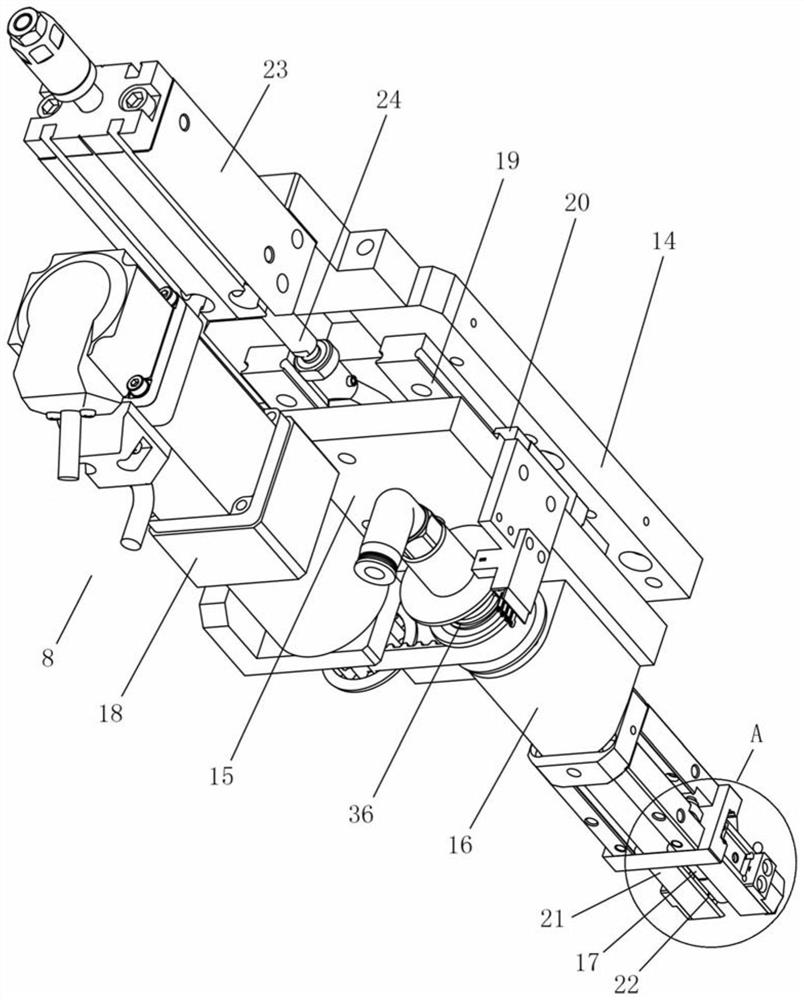

[0028] like Figure 1-6 As shown, a kind of automatically oriented hinge intelligent assembly equipment includes a frame 1 and an oil cylinder orientation device 2 installed on the frame 1, the frame 1 is provided with a carrier track 3, and the oil cylinder orientation device 2 It consists of an orientation mechanism 4 and a riveting mechanism 5. The orientation mechanism 4 includes a mounting frame 6, a fixing assembly 7 and a rotating positioning assembly 8. The mounting frame 6 is erected above the carrier rail 3 and fixedly installed on the On the frame 1, the fixing assembly 7 and the riveting mechanism 5 are installed on one side of the installation frame 6, and the rotation positioning assembly 8 is installed on the other side of the installation frame 6 obliquely. .

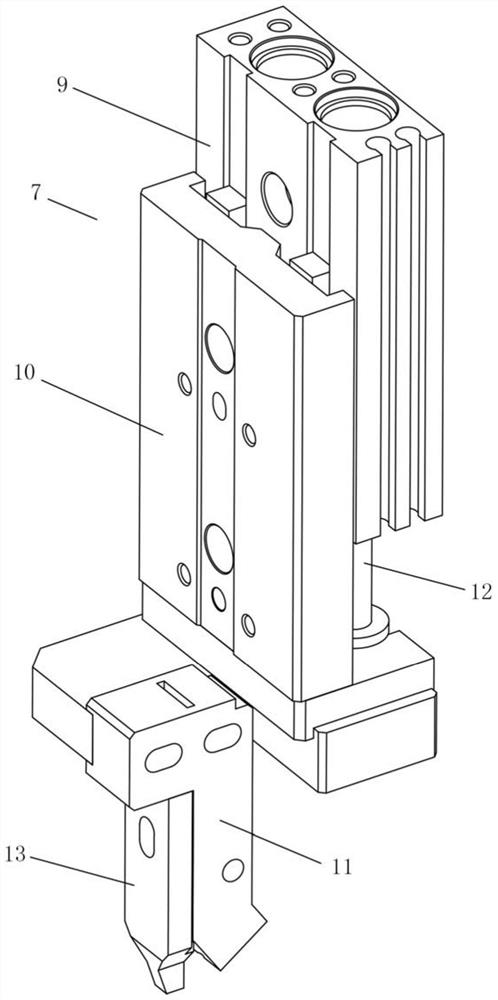

[0029] Preferably, the fixing assembly 7 includes a first drive 9, an engaging block 10 and a positioning block 11, the first drive 9 is installed on the mounting frame 6, and the first drive 9 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com