Fixtures for Quartz Wafer Edger

A quartz wafer and edger technology, which is applied to machine tools, grinders, and manufacturing tools suitable for grinding workpiece edges, can solve the problems of inaccurate positioning, low positioning accuracy, and low wafer edge grinding accuracy, and achieve automatic Positioning and clamping, realizing the effect of automatic positioning operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

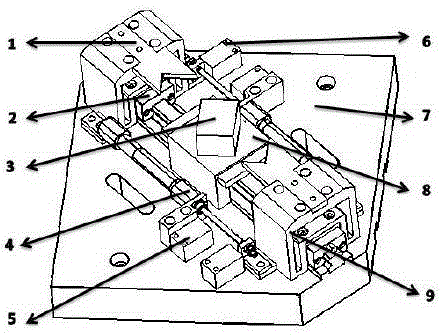

[0019] Such as figure 1 As shown, the fixture used for the quartz wafer edger of the present invention includes a base 7 on which a guide rail 2 is fixedly arranged; two ends of the guide rail 2 are movably connected to two sliders 9; the top of each slider 9 is fixedly arranged There are positioning claws 1, and two positioning claws 1 are arranged oppositely; two sliders 9 are driven by the cylinder 4;

[0020] The middle part of the guide rail 2 is fixedly provided with an air intake platform 8, and the suction platform 3 is fixedly provided on the air intake platform 8; the suction platform 3 is located between the two positioning claws 1;

[0021] The suction table 3 is provided with a negative pressure generating device; the negative pressure generating device is connected to a negative pressure sensor 6; the negative pressure sensor 6 is connected to the cylinder 4 through a signal line;

[0022] The suction table 3 is provided with a position sensor 5; the position se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com