A frame structure switchable track type maintenance trolley

A technology for switching rails and frame structures, which is used in railway inspection vehicles, railway car body parts, railway vehicle shape measuring instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

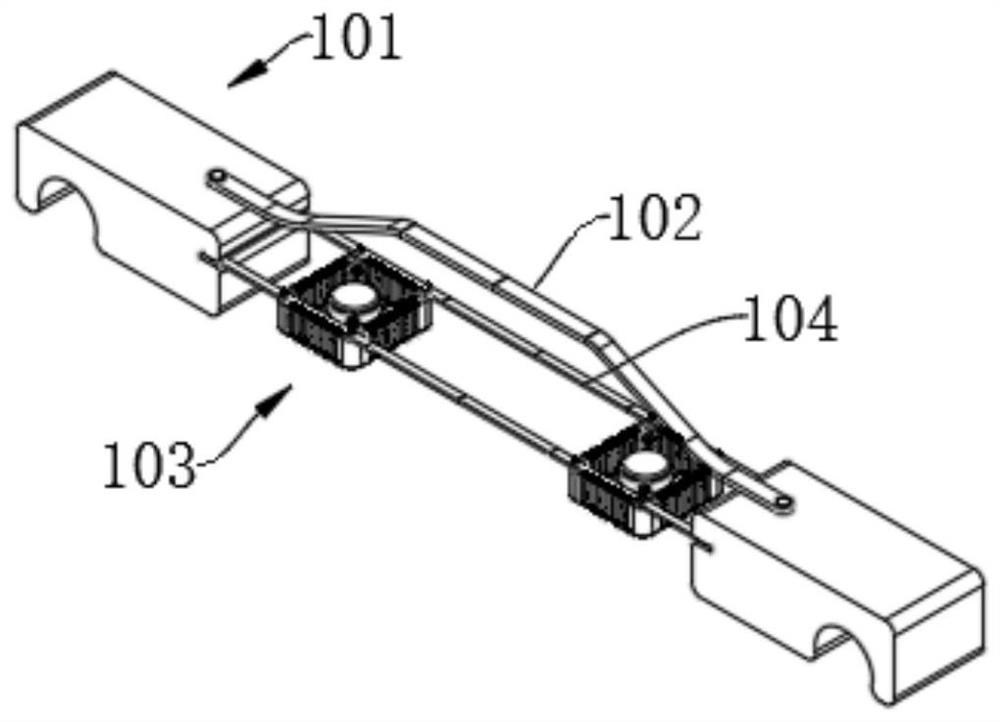

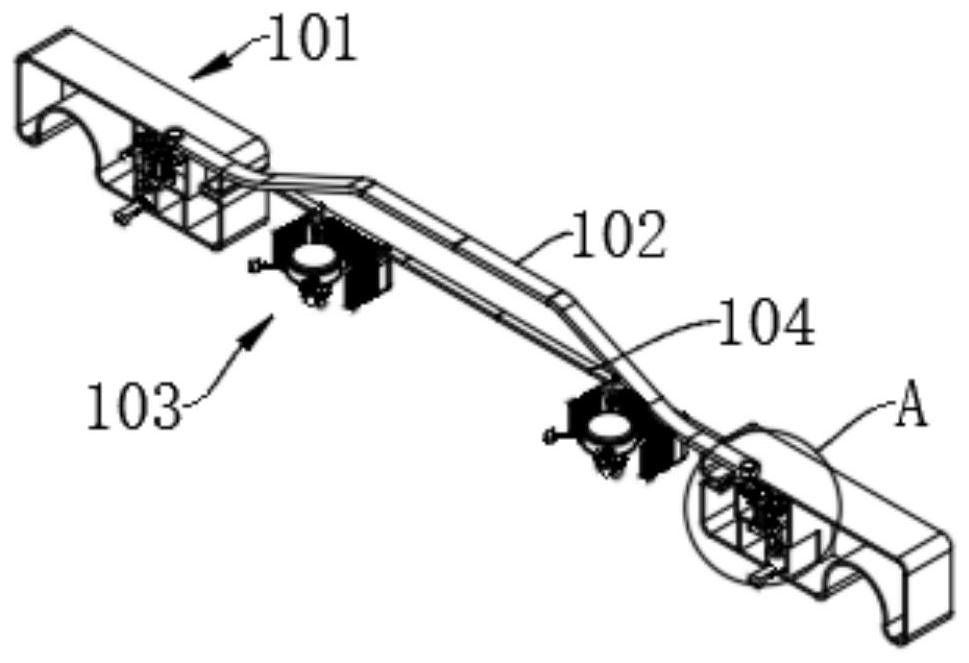

[0028] refer to Figure 1-6 , a frame structure switchable track-type maintenance trolley, including: a track drive device 101, a rotating swing arm 102 and a sensor stabilization device 103, the track drive device 101 is provided with two groups corresponding to the left and right sides, two groups of track drive devices 101 The upper surfaces are flexibly connected by rotating swing arms 102, and the two groups of track driving devices 101 are flexibly connected by two groups of rotating connecting rods 104 at the upper positions in the middle. An active parallelogram, two groups of rotating connecting rods 104 are equipped with sensor stabilizing devices 103 on the left and right sides;

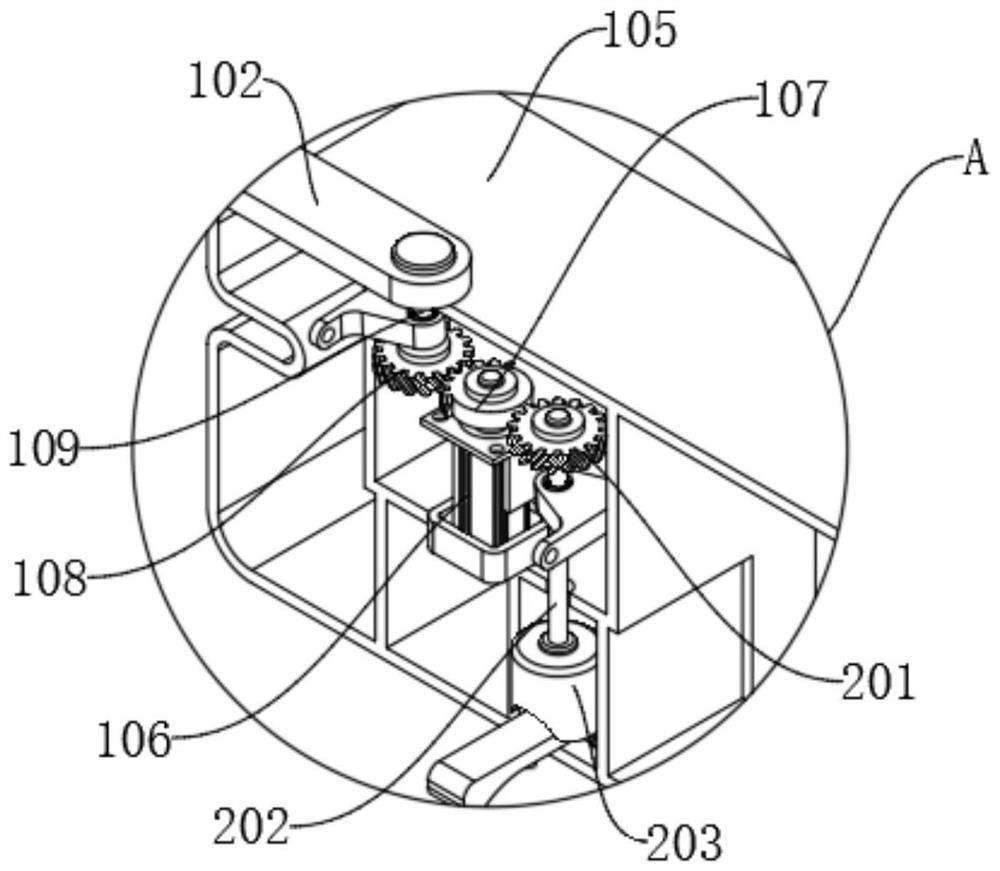

[0029] Track driving device 101 comprises: driving housing 105, servo motor 106, rotating half gear 107, rotating gear 108 and rotating shaft 109, driving mechanism is fixedly installed inside driving housing 105 right side, and servo drive housing 105 middle part left side inside is fixed...

Embodiment 2

[0033] Embodiment 2: the difference based on Embodiment 1 is;

[0034] The track fixing mechanism includes: rotary gear 201, rotary shaft 202, lower pressure block 203, torsion spring 204, rotary spring 205 and movable fixed block 206, the right side of the rotating half gear 107 is meshed with the left side of the rotary gear 201, and the rotary gear 201 shaft The center is fixedly connected with the upper end of the rotary shaft 202, and one end of the torsion spring 204 is fixedly installed in the middle of the rotary shaft 202, and the other end of the torsion spring 204 is fixedly connected with the inner wall of the drive housing 105, and the lower end of the rotary shaft 202 is fixedly connected with the upper end of the lower pressure block 203. There are two groups of movable fixed blocks 206 installed on the lower side of the pressing block 203. The two groups of movable fixed blocks 206 are movably connected to the inner one end axis through the rotating shaft and th...

Embodiment 3

[0037] Embodiment 3: Based on Embodiment 1 and 2, the difference is;

[0038] The sensor stabilizing device 103 includes: movable rotating block 301, telescopic linkage pipe 302, linkage spring 303, stabilizing ring housing 304, miniature hydraulic rod 305, fixed shaft 306, rotating rod 307, connecting block 308 and sensor installation housing 309, rotating connecting rod Four groups of movable rotating blocks 301 are movably installed on 104, and the movable rotating blocks 301 are in pairs. The movable rotating blocks 301 are connected by telescopic linkage tubes 302, and the inner side of the telescopic linkage pipes 302 is fixedly connected with one end of the linkage spring 303. The other end of the linkage spring 303 is fixedly connected to the outer wall of the stable ring housing 304, the upper end of the stable ring housing 304 is fixedly installed with a fixed shaft 306, and one end of the miniature hydraulic rod 305 is movably installed on the fixed shaft 306, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com