Telescopic grab bucket anti-shaking mechanism

An anti-shaking, telescopic technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of inability to realize fast positioning, affect production efficiency, breakage of scissors and forks, etc., and achieve novel structure, high positioning accuracy, and anti-shaking good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the invention will be described in further detail below in conjunction with the accompanying drawings.

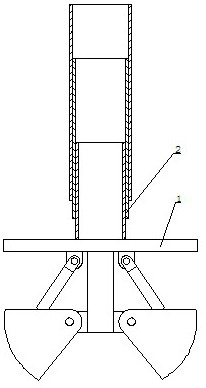

[0011] see figure 1 , a telescopic grab anti-sway mechanism, including a grab 1, also includes an anti-sway mechanism 2, the grab 1 is mounted on the bottom of the anti-sway mechanism 2. The anti-sway mechanism 2 is composed of no less than two pipes whose cross-sectional dimensions are sequentially reduced and which are sequentially socketed and relatively slidable. The pipe material can be made of a round pipe or a polygonal pipe.

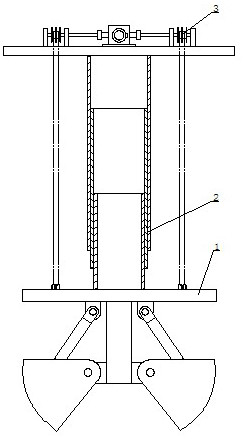

[0012] figure 2 It is a schematic diagram of the application of the present invention, the lifting mechanism 3 is installed on the upper end of the anti-shake mechanism 2, and the lifting mechanism 3 is connected with the grab bucket 1 through a belt (or wire rope), so that when the lifting mechanism 3 is lifting or lowering the grab bucket 1 Among them, the anti-sway mechanism 2 performs telescopic action synchronous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com