Air returning, dehumidifying and heating device of sludge drying equipment

A technology of sludge drying and heating device, which is applied in drying gas arrangement, lighting and heating equipment, dewatering/drying/concentrating sludge treatment, etc., can solve the problem of poor dehumidification effect, etc. rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

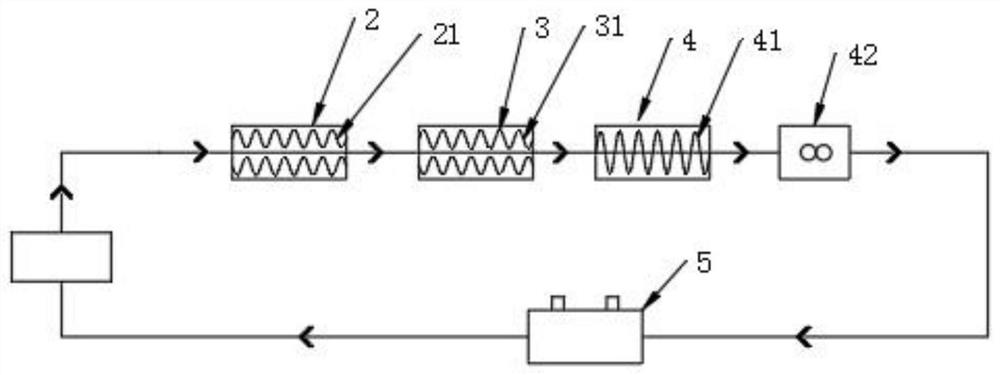

[0019] Embodiment: a return air dehumidification heating device for sludge drying equipment, such as figure 1 As shown, it includes a normal temperature coil 2, an evaporator 3, a condenser 4 and a compressor 5 through which the return air passes sequentially. The normal temperature coil 2 is provided with a cooling pipe 21 for supplying water to the external cooling tower, and the evaporator 3 is provided with There is a pipeline 31 for cooling and evaporating, and a condenser coil 41 is installed in the condenser 4. The air is cooled by the evaporator 3 to condense the humid air and then enters the condenser coil 41 to be heated, and the gas in the condenser coil 41 releases heat Return to the pipeline 31 after liquefaction.

[0020] The humid air passing through the sludge drying equipment is sent into the normal temperature coil 2, and the temperature of the humid air drops below the dew point temperature, and part of the moisture in the humid air will condense into water ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap