Slide valve loading and unloading structure capable of being accurately controlled, screw compressor and control method

A technology of loading and unloading and slide valve, which is applied in the field of compressors, can solve the problems of low stability and reliability, increased useless work, etc., and achieve the effects of reliable structure, improved reliability and reduced useless power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

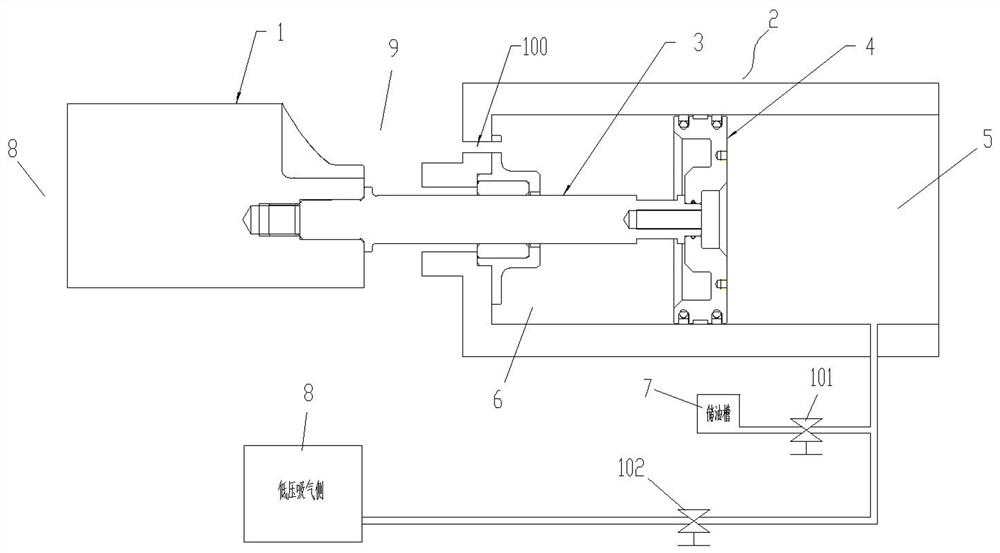

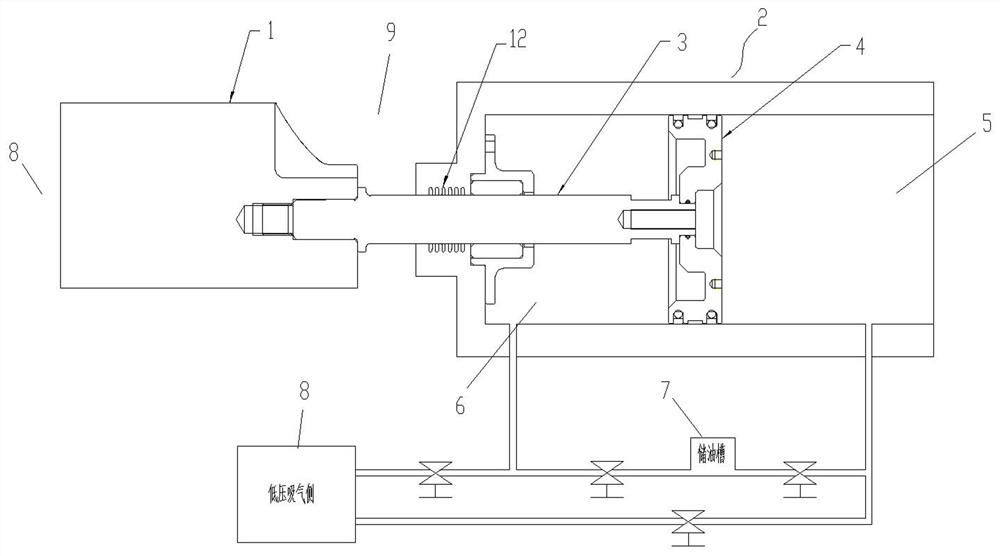

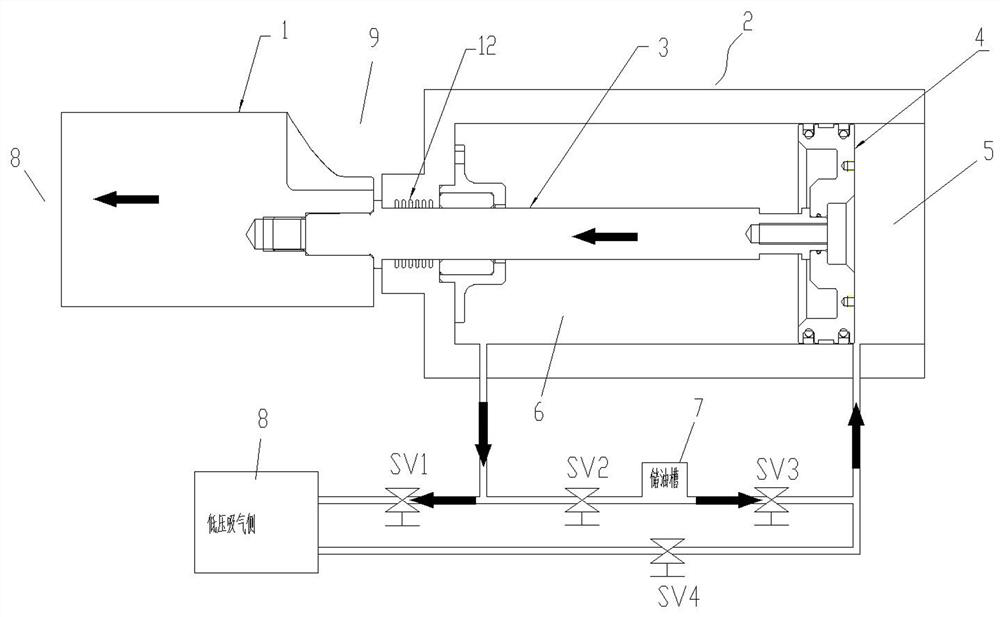

[0027] Such as figure 2 , 3 Shown is a preferred embodiment of the loading and unloading structure of the spool valve provided by the present invention, which includes a spool valve 1 and a piston-cylinder transmission mechanism 2 connected to the spool valve 1 through a spool valve rod 3 (piston rod). In this embodiment, the left cavity 6 and the right cavity 5 of the piston 4 in the piston-cylinder transmission mechanism 2 are both oil cylinders. The left and right oil cylinders 6 and 5 of the piston 4 are all communicated with the low-pressure suction side 8 of the compressor through the oil circuit, and the left and right oil cylinders 6 and 5 are also connected to the high-pressure discharge of the compressor through the oil storage tank 7 by the oil circuit. The gas side 9 communicates. The oil cylinders 6 and 5 on the left and right sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com