Horizontal flue type demister

A horizontal flue and mist eliminator technology, which is applied in chemical instruments and methods, gas treatment, and dispersed particle separation, etc., can solve the problem of limited demisting effect of corrugated plates, limited mist condensation effect, unfavorable horizontal flue type mist eliminator Promote the use of other issues to achieve the effect of improving the capture effect and improving the effect of defogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

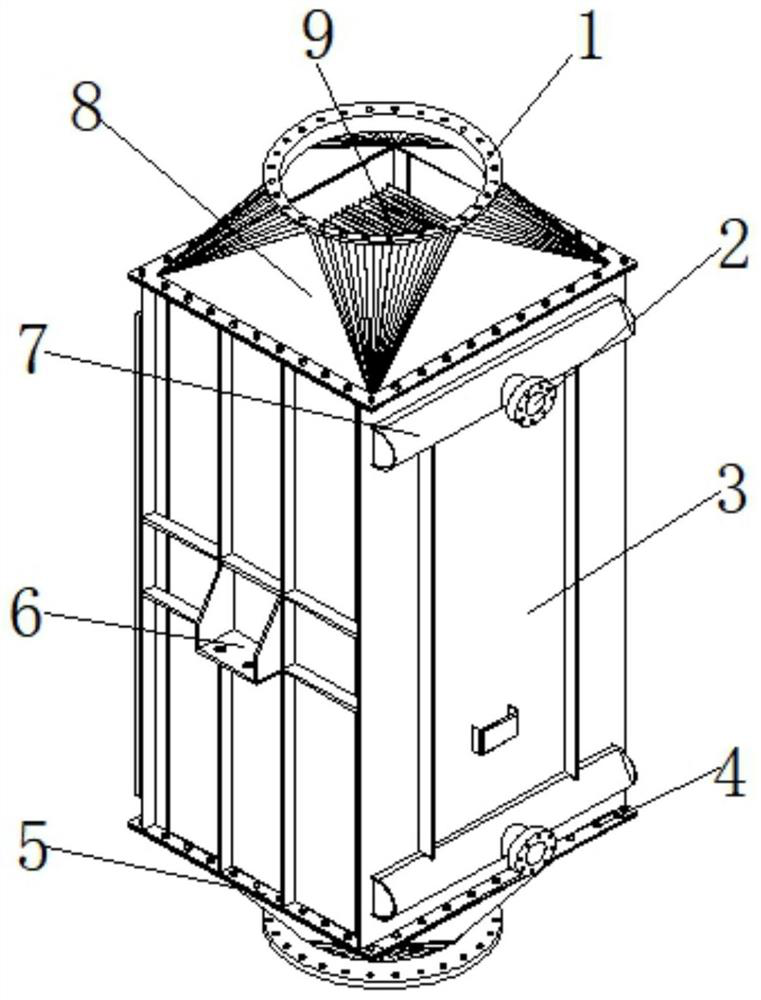

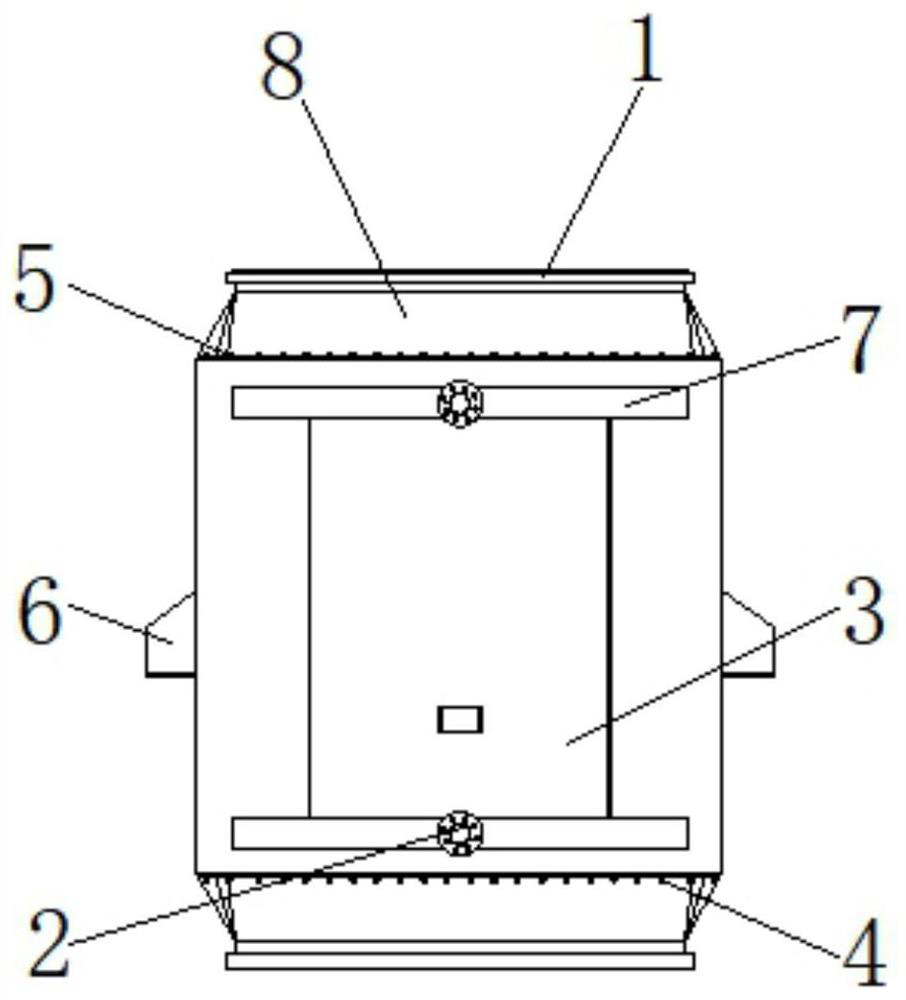

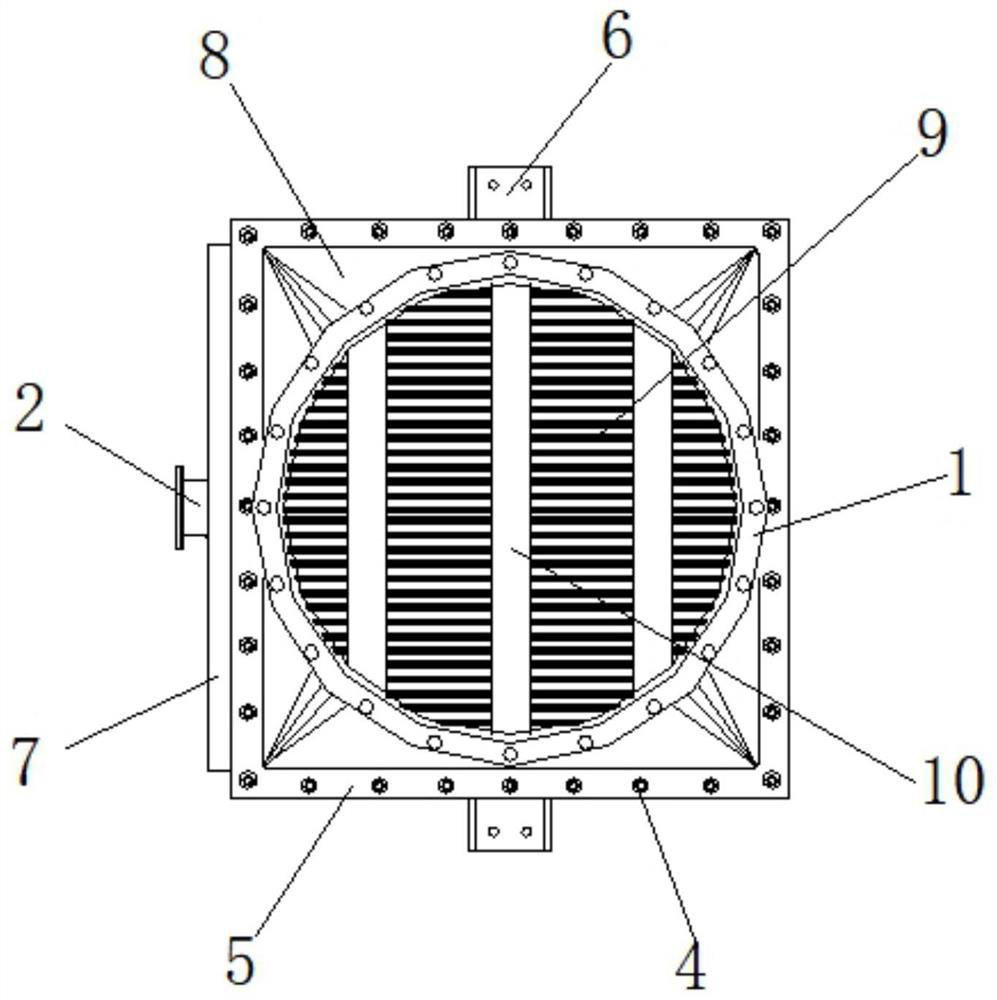

[0029] Example 1, such as Figure 4 , 5As shown in and 7, when the mist passes between multiple sets of screens A902, a part of the mist will gradually adhere after touching the surface of the screen A902, and a part of the mist will gradually adhere when it touches the inner side of the arc-shaped groove 903 On the inner side wall of the arc-shaped groove 903, another part of the mist touches the surface of the interlaced screen B904, is caught by the through holes on the surface of the screen B904, and a part of the mist adheres when passing through multiple sets of auxiliary rods 13. On the surface of the auxiliary rod 13, when the fog beads attached to the surface of the auxiliary rod 13, the corrugated plate 901, the screen A902, the arc groove 903 and the screen B904 gradually collide and increase, under the influence of gravity, the heavier fog beads Will gradually flow downwards, thereby flowing into the bottom of the square bin 3.

Embodiment 2

[0030] Example 2, such as Figure 4 , 5 , 7 and 8, when the defogged flowing air passes through the square bin 3, the four sets of fan blades 113 are blown to rotate, thereby driving the collar 112 to rotate. Also constantly rotate, when spheroid 116 moved on the arc projection 115, articulated rod 118 was jacked up gradually, and spring 117 was stressed and shortened, after spheroid 116 lost contact with arc projection 115, due to spring 117 elastic recovery force, forcing the end of the hinged rod 118 close to the ball 116 to quickly hit the surface of the collar 112 to produce a knocking effect, and the vibration generated by the knocking is transmitted to the multiple groups of screens A902 through the connecting frame B12, so that it is attached to the surface of the screen A902 The mist beads gather quickly due to vibration and flow downward when they are small.

[0031] Working principle: Before use, connect one end of the square chamber 3 with the mist supply device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com