Multi-steel-bar cutting equipment and using method thereof

A technology for cutting equipment and steel bars, applied in the field of multi-steel steel cutting equipment, can solve the problems of low construction efficiency of grinding wheel cutting machines, unsatisfactory construction efficiency, end deformation and distortion, etc., and achieve the effects of efficient steel bar cutting operations, improving molding quality, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

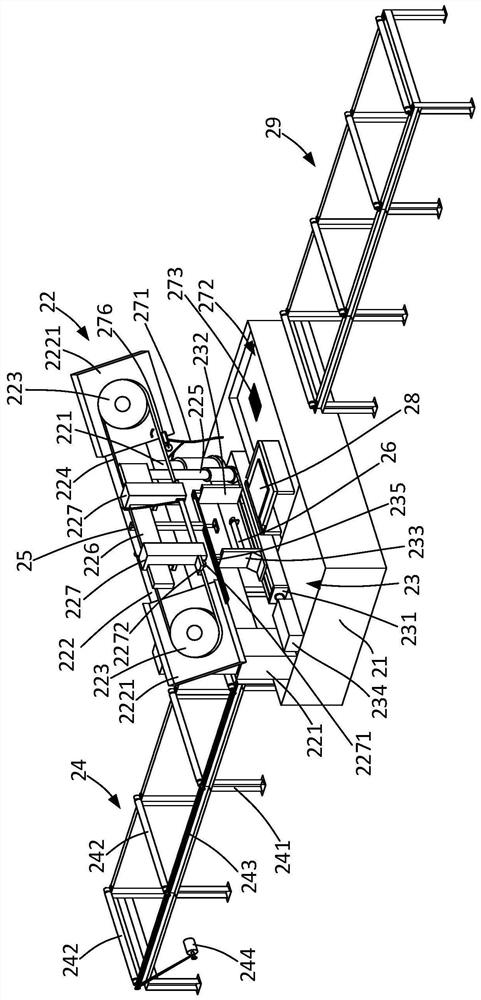

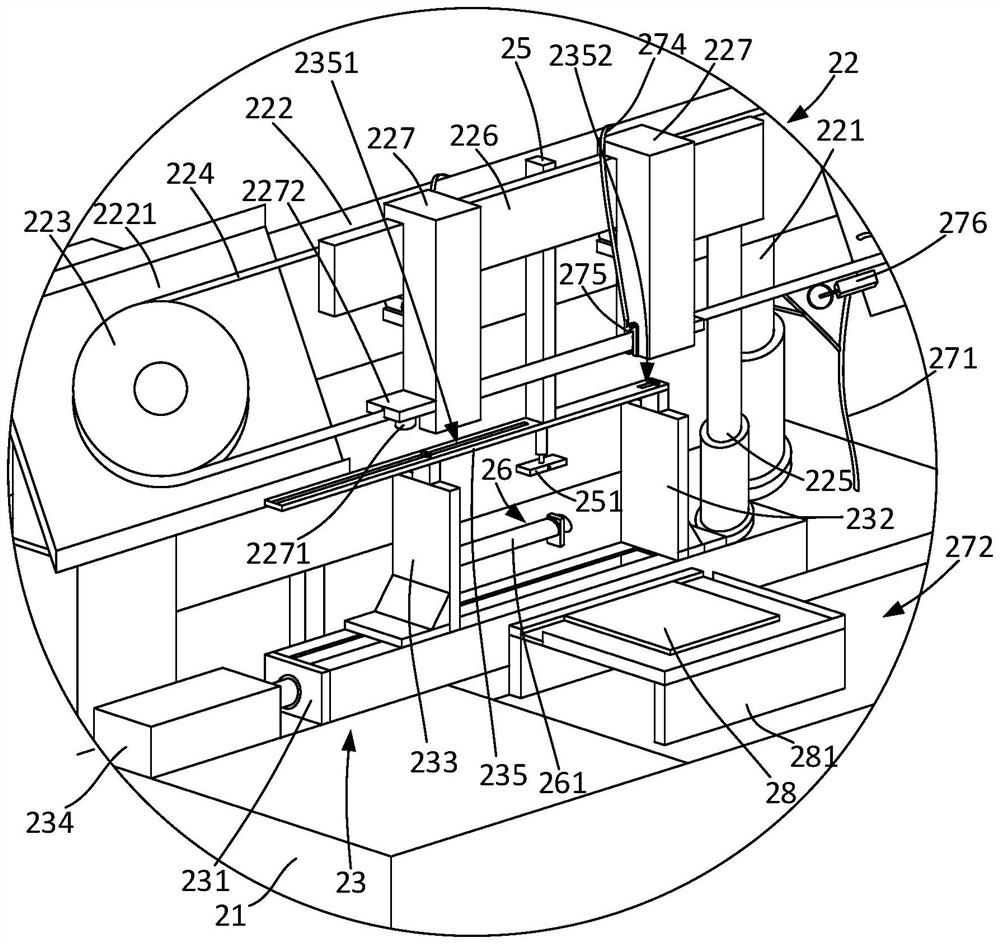

[0038] refer to figure 1 , the present invention provides a multi-steel bar cutting device and its use method, which are used to improve the cutting efficiency of steel bars, and can cut multiple steel bars at one time, and the number of clamped steel bars can be adjusted by adjusting the clamping distance of the clamping mechanism, that is, Realized the adjustment of the number of steel bars cut at one time. Further, the cutting mechanism is arranged close to the clamping mechanism, and the steel bar to be cut is clamped by the clamping mechanism, and the position where the cutting mechanism cuts the steel bar is close to the position where the clamping mechanism clamps the steel bar, so that the stability of the steel bar is good during the cutting process, ensuring Improve the quality of steel bar cuts and avoid deformations such as horsesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com