Tool status online monitoring method and management system

A tool and state technology, used in manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as wear and tool breakage, achieve high monitoring sensitivity, reduce the rate of processed products, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below through specific embodiments.

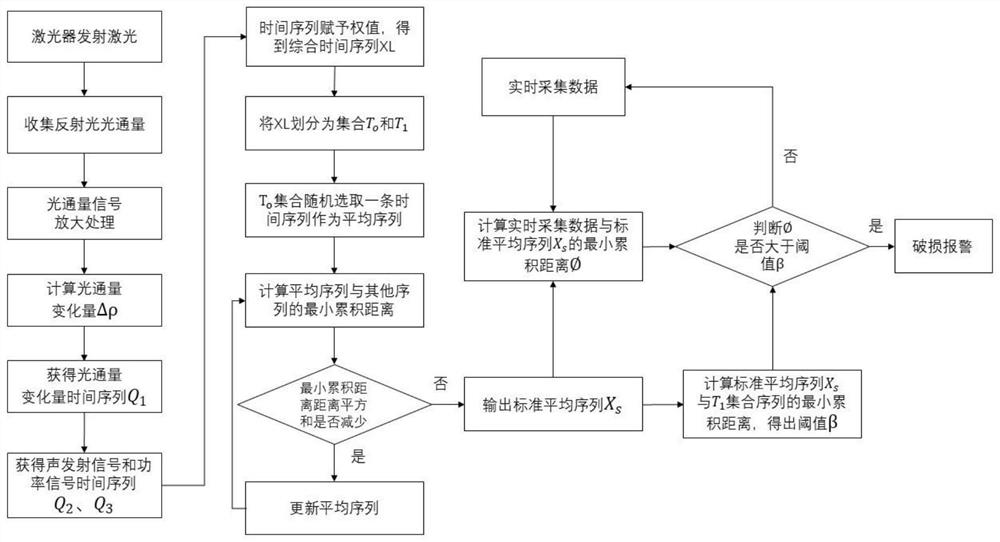

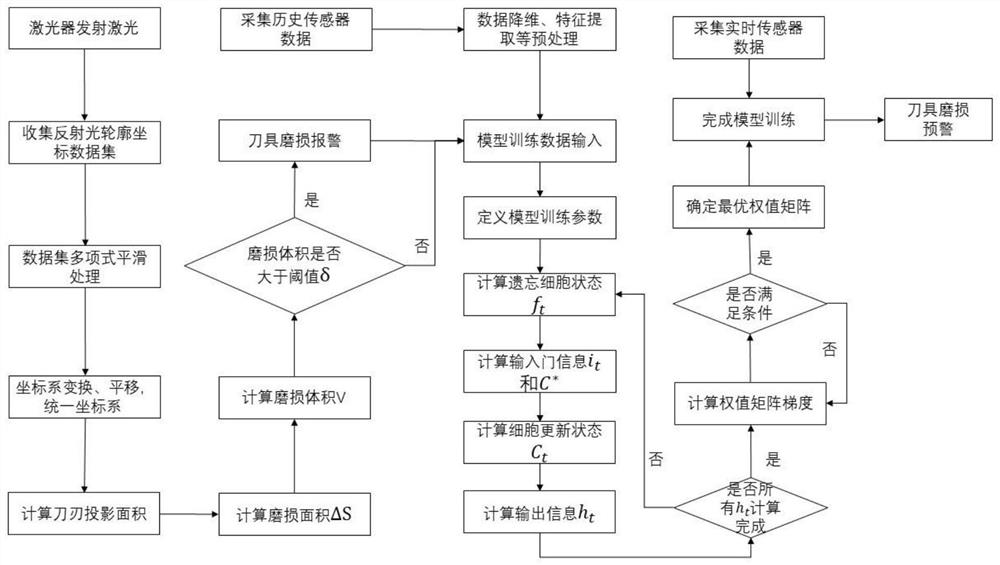

[0045] An online monitoring method for tool status, including damage monitoring and wear monitoring; damage monitoring mainly monitors tool damage, which requires high effectiveness, and uses an improved multi-feature time series dynamic matching algorithm for monitoring; wear monitoring mainly monitors tool wear, It requires high accuracy of tool wear and belongs to predictive monitoring, and uses an improved Laser-cyclic neural network model for monitoring.

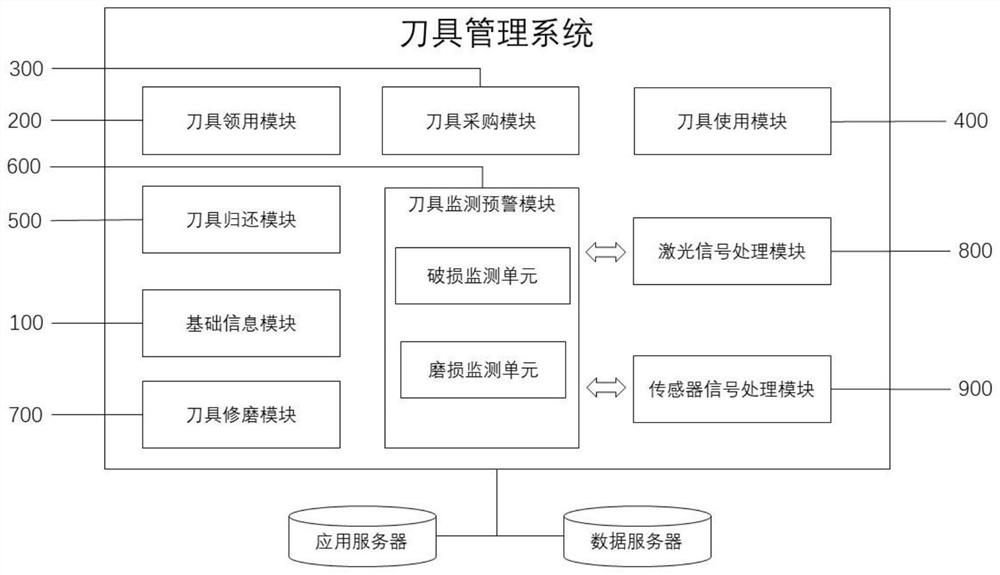

[0046] Taking the RT-ITMS intelligent tool management system as a prototype, the implementation of the present invention is described in detail. RT-ITMS intelligent tool management system is developed based on the Internet of Things, big data and artificial intelligence technology. It has complete tool management functions and database management functions, and can manage the entire life cycle of different manufacturers and diff...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap