Waste glass cement pipe processing equipment

A technology for waste glass and processing equipment, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of low processing efficiency, time-consuming and laborious, and achieve the effect of preventing stagnation and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

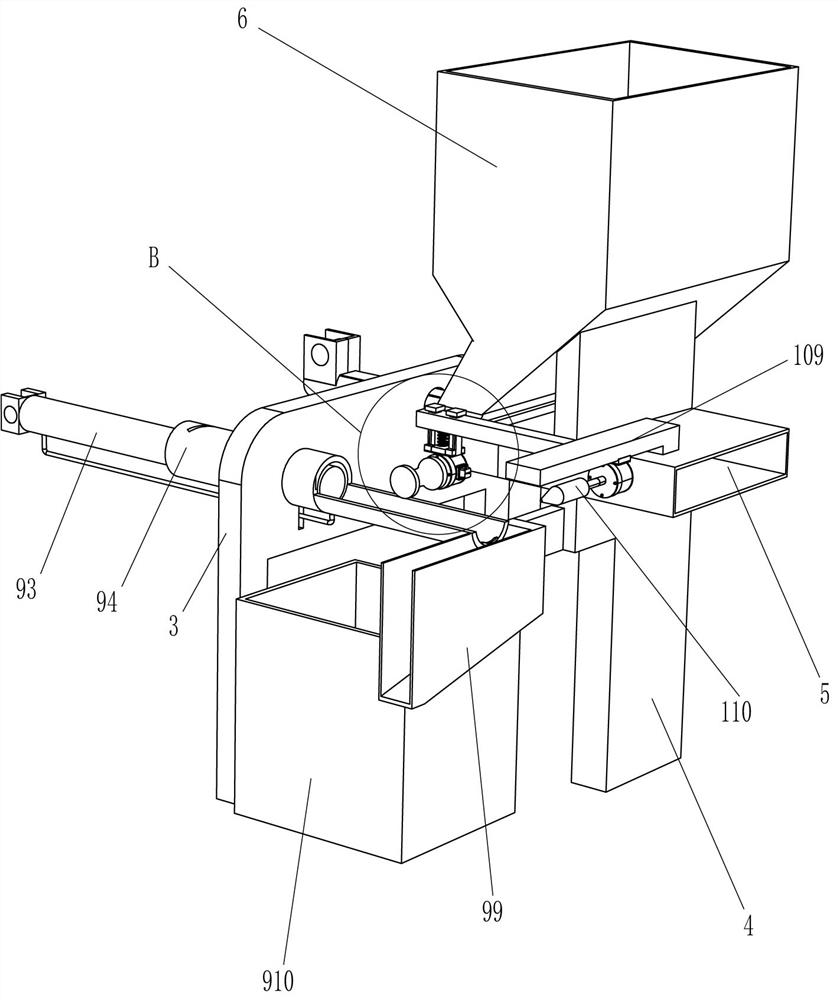

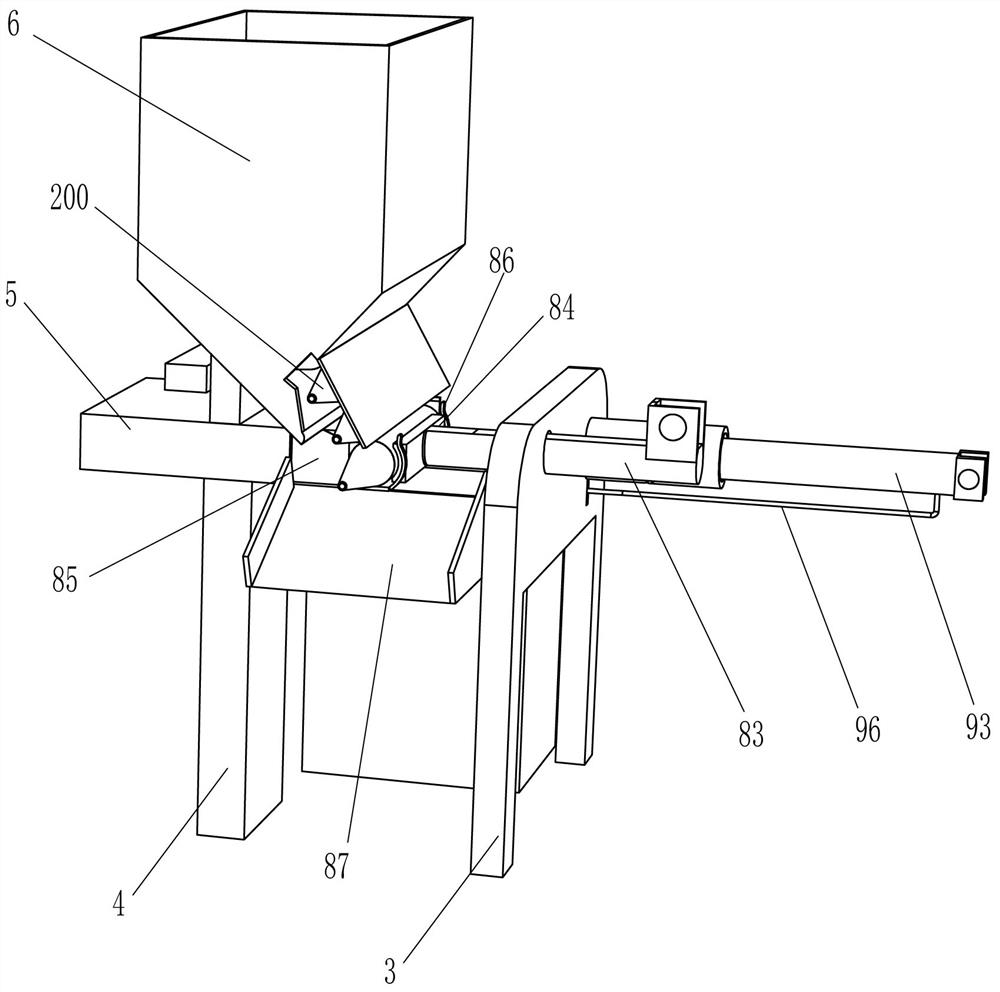

[0030] A waste glass rubber hose processing equipment, such as Figure 1-7 As shown, it includes a base 1, a mounting frame 2, a guide frame 3 and a support frame 4, and also includes a guide frame 5, a blanking frame 6, a driving mechanism 7, an end cutting mechanism 8 and a material extruding device 9, and the base 1 The left side of the top is connected with the installation frame 2, the top right side of the base 1 is connected with the guide frame 3, the top of the base 1 on the right side of the guide frame 3 is connected with the support frame 4, the upper part of the support frame 4 is embedded with a guide frame 5, and the guide The inner bottom of the frame 5 is left high and the right bottom is inclined, the top of the support frame 4 is connected with the blanking frame 6, the blanking frame 6 communicates with the guide frame 5, the driving mechanism 7 is installed on the mounting frame 2, and the driving mechanism 7 An end cutting mechanism 8 and a material extru...

Embodiment 2

[0036] On the basis of Example 1, such as figure 1 , figure 2 , image 3 with Figure 8 Shown, also includes gift-giving mechanism 10, and gift-giving mechanism 10 includes 1 / 4 toothless gear 101, rotating rod 102, full-toothed gear 103, belt drive assembly 104, fixed frame 105, drive shaft 106, rotating disk 107, positioning Bar 108, connecting frame 109 and conical head electric roller 110, on the drive shaft 72 of three-quarter missing tooth plate 73 lower side, be connected with 1 / 4 missing tooth gear 101, the right side on the mounting bracket 2 is connected There is a rotating rod 102, the top of the rotating rod 102 is connected with a full-toothed gear 103, and the full-toothed gear 103 meshes with a quarter missing tooth gear 101, and the top of the base 1 on the right side of the support frame 4 is connected with a fixed frame 105, and the fixed frame 105 The top left side of the top is connected with a transmission shaft 106 in a rotating manner, and a belt driv...

Embodiment 3

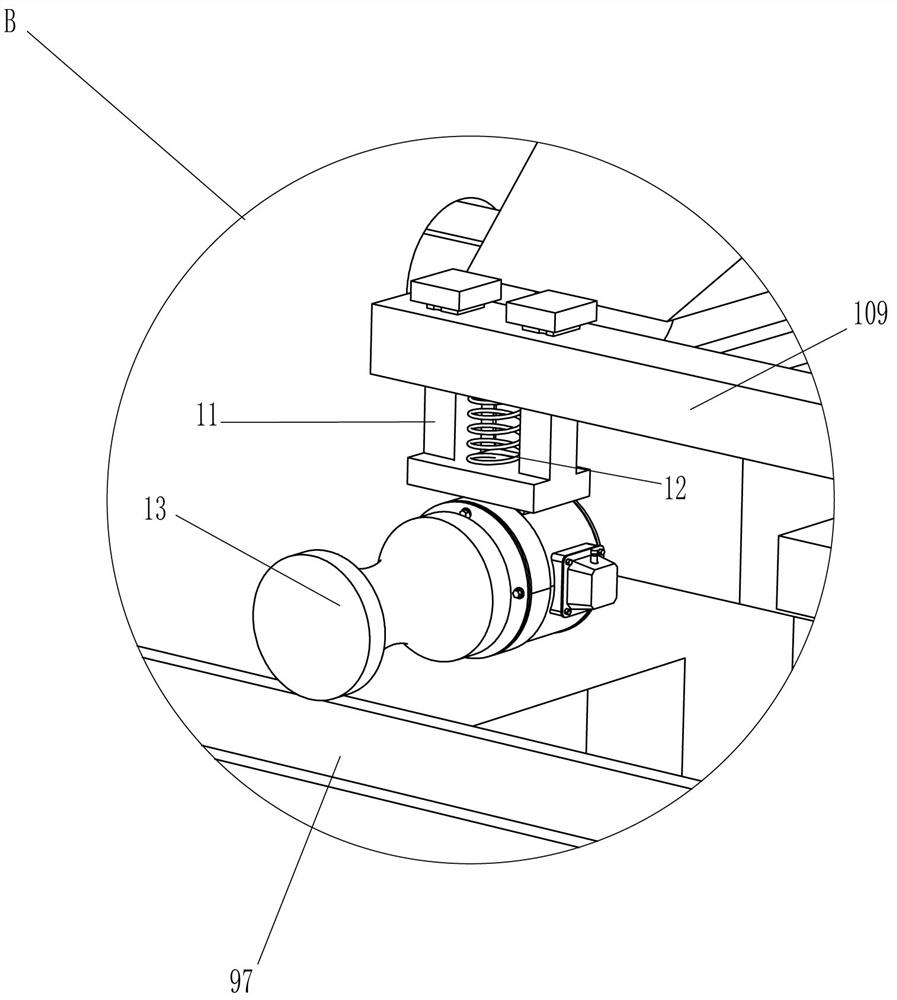

[0039] On the basis of Example 2, such as Figure 9 Shown, also include sliding frame 11, compression spring 12 and feeding roller 13, the top left side of connecting frame 109 is vertically slidably connected with sliding frame 11, and sliding frame 11 runs through connecting frame 109, and the inner top of sliding frame 11 is connected There is a compression spring 12, the top of the compression spring 12 is connected with the bottom of the connecting frame 109, and the bottom of the sliding frame 11 is connected with a feeding roller 13.

[0040] The compression spring 12 can make the feed roller 13 and the discarded glass glue plastic tube 200 after the bottle mouth is cut off on the semicircular pipe 97 close to each other, and the feed roller 13 is manually activated to make the feed roller 13 rotate clockwise, and the feed roller 13 rotates clockwise and the taper head The cooperation of the electric roller 110 can make the waste glass glue plastic pipe 200 after the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com