Flexible guide rail of the first conveying channel of the packaging machine

A technology of flexible guide rails and conveying channels, applied in packaging machines, mechanical conveyors, packaging, etc., can solve the problems of box collision deformation, box blockage, etc., and achieve the effect of avoiding box blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

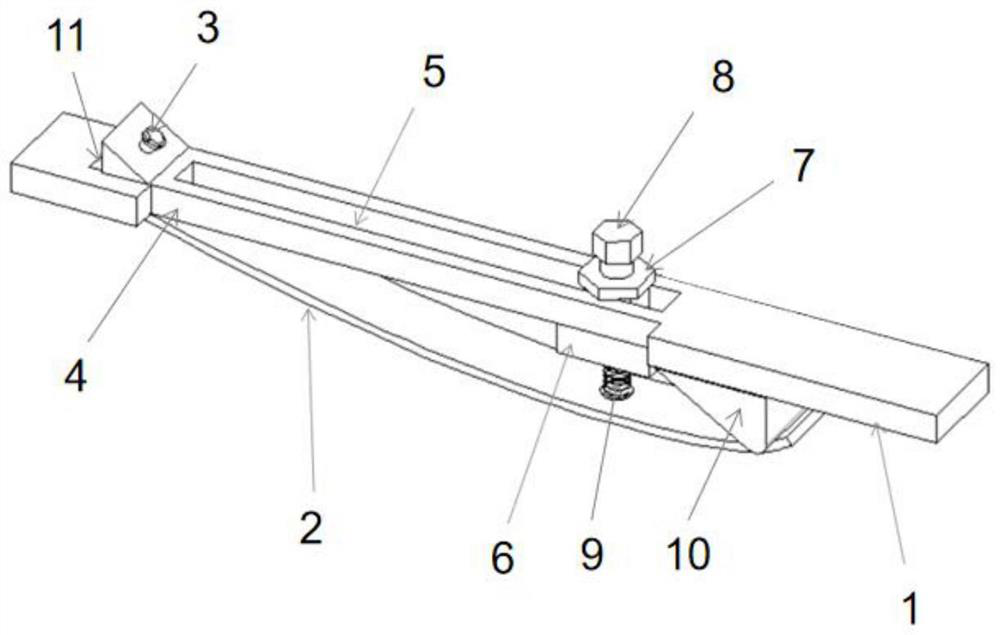

[0022] as attached figure 1 As shown, the flexible guide rail of the first conveying channel of the packaging machine includes a guide rail bracket 1, a guide rail adjustment device, a pressure adjustment device and an elastic guide rail 2. The pressure adjustment device can adjust the position and pressure of the contact point of the elastic guide rail 2, and the guide rail adjusts The device can adjust the length of the elastic guide rail 2. One end of the elastic guide rail 2 is a fixed end, which is connected to the back of the guide rail bracket 1, and the other end is fixed by the guide rail adjusting device.

Embodiment 2

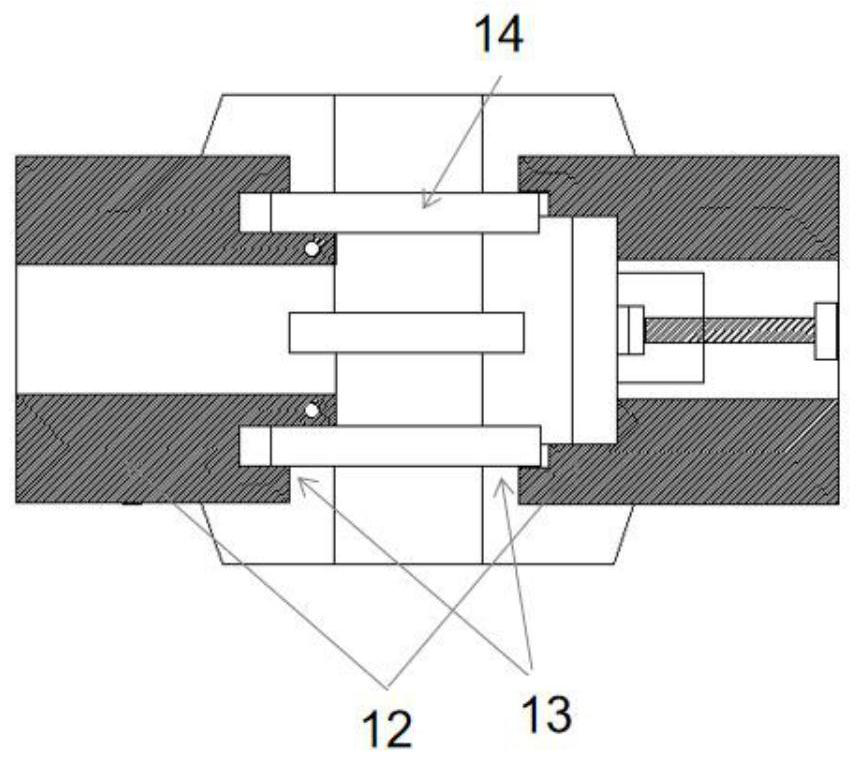

[0024] Based on Embodiment 1, Embodiment 2 further defines the guide rail adjusting device. One end of the guide rail bracket 1 away from the fixed end of the elastic guide rail 2 is bifurcated, the forward extending part is provided with an elastic guide rail hole 11, and the other part extends obliquely upward. The guide rail adjustment device can be a set nut connection or a pin connection. When it is connected with a fixing nut, the upwardly extending part is provided with a threaded hole, the unfixed end of the elastic guide rail 2 passes through the elastic guide rail hole 11 , and the fixing nut is threadedly matched with the threaded hole to push the elastic guide rail 2 tightly. When it is a pin connection, positioning holes are provided on the inclined upward extension part and the corresponding position on the elastic guide rail, and a row of adjustment holes are opened on the elastic guide rail. The unfixed end of the elastic guide rail 2 passes through the elastic ...

Embodiment 3

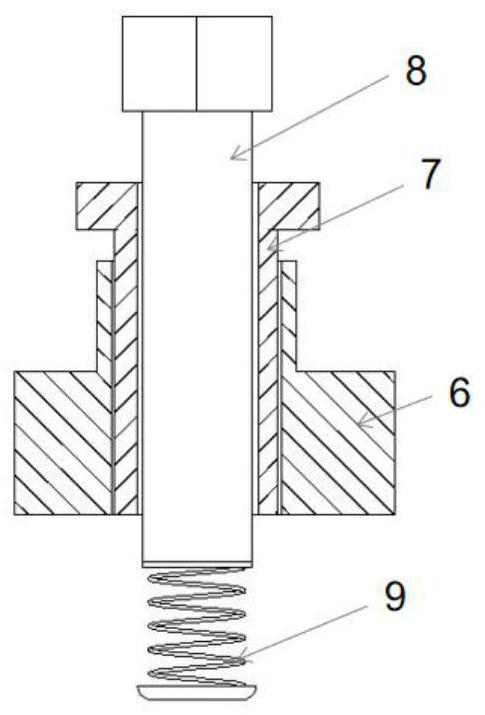

[0026] Based on Embodiment 1 or Embodiment 2, Embodiment 3 further defines the pressure regulating device. The pressure regulating device includes a screw 8, a slider locking nut 7, a slider 6 and an elastic part. The bottom of the screw is connected with an elastic part. The slider locking nut 7 is T-shaped and has a threaded hole in the middle. The outer wall is engraved with threads, the threaded hole is matched with the thread of the screw 8, and the thread of the outer wall is matched with the thread of the slider.

[0027] The guide rail bracket 1 can open a long chute 5 in the middle, the screw 8 of the pressure regulating device passes through the long chute 5 and is threaded to the slider 6 , and the elastic part at the bottom of the screw 8 bears against the top surface of the elastic guide rail 2 . The guide rail bracket 1 can also open a row of adjustment holes in the middle thereof, the screw rod 8 of the pressure adjustment device passes through the adjustment ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com