A garment processing technology

A processing technology and clothing technology, applied in the field of clothing processing technology, can solve problems such as difficulty in removing thread ends, enhanced adhesion of thread ends and clothing, etc., and achieve the effect of convenient subsequent cutting and sewing processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0041] The embodiment of the present application discloses a garment processing technology, which includes the following steps:

[0042] Step 1. Prenatal ironing of clothing fabrics;

[0043] Step 2, cutting the garment fabric into garment pieces of certain specifications;

[0044] Step 3, sewing the garment parts in step 2 according to the corresponding connection relationship, so that the garment is initially formed;

[0045] Step 4. Remove the thread ends on the surface of the garments from the sewn and formed garments through the thread removal equipment, and then iron the garments after delivery;

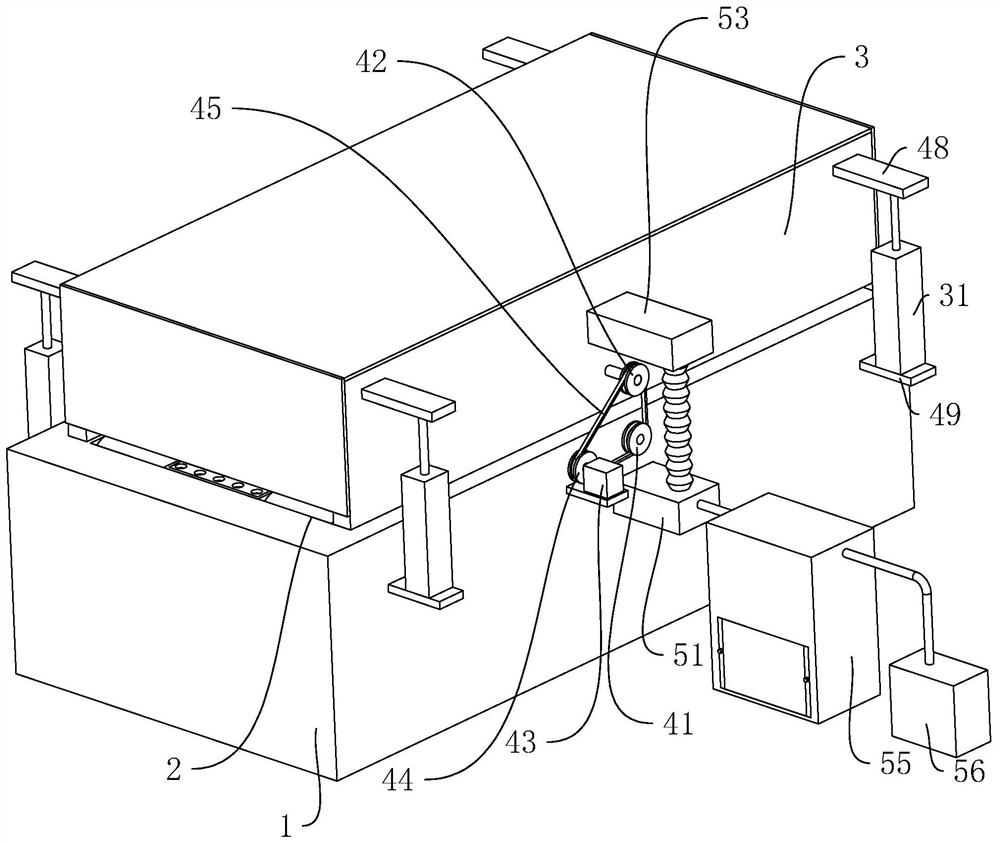

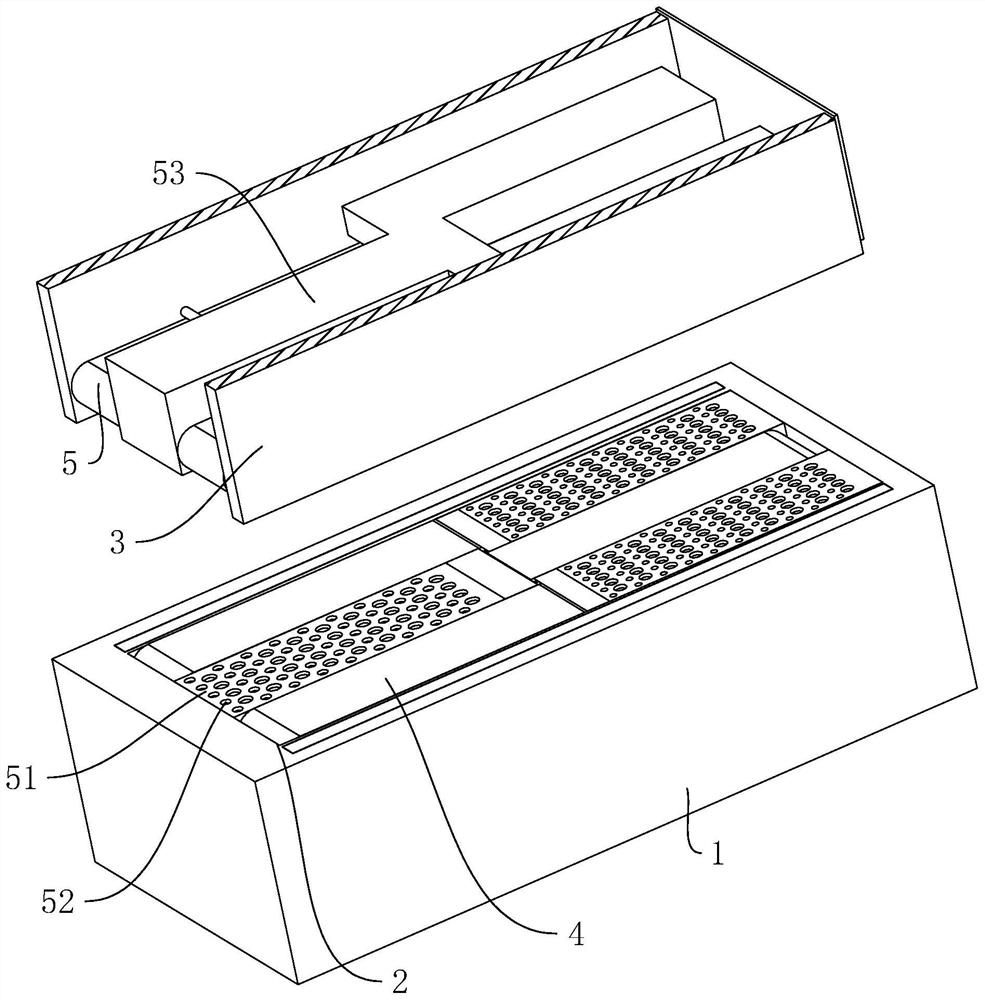

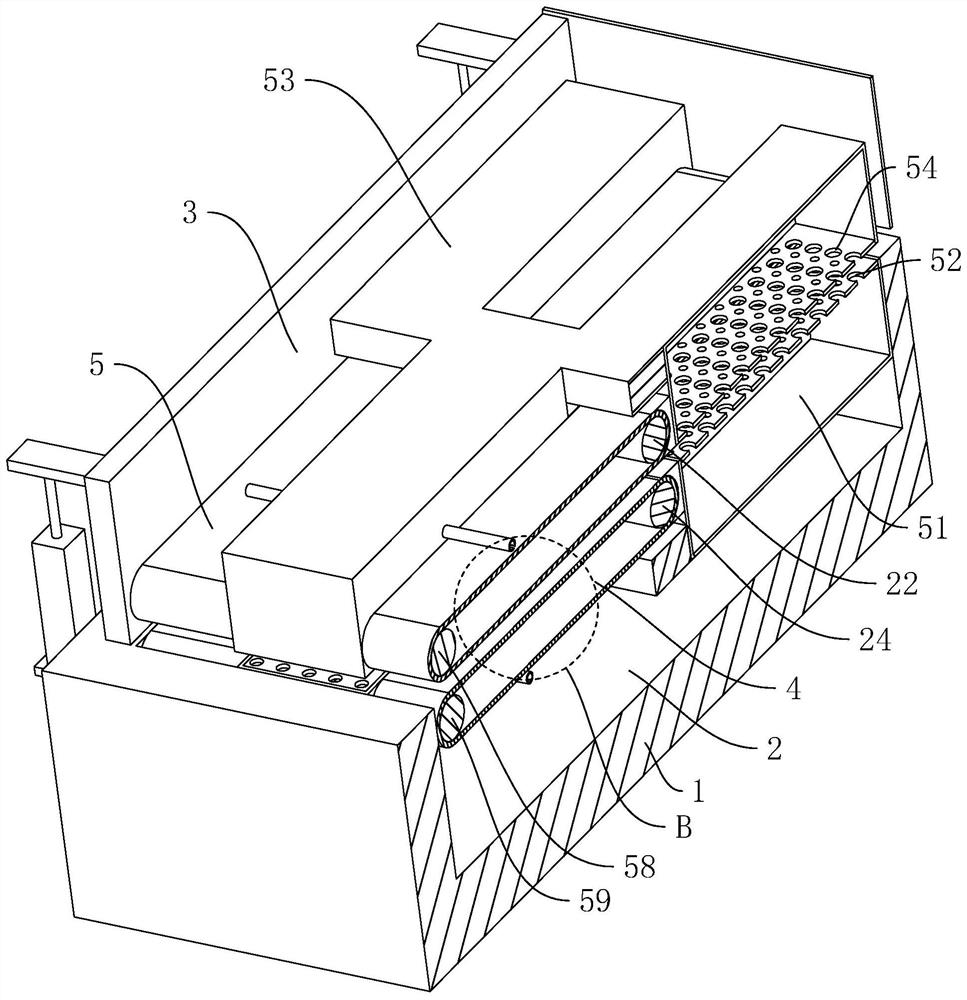

[0046] Lint removal equipment as described in step 4, refer to figure 1 and figure 2 , including the main platform 1, the moving direction of the clothing is parallel to the length direction of the main platform 1, the two sides of the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com