A bending structure for container house assembly

A technology of container houses and bending parts, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of loose connection and inability to move the connecting parts, and achieve convenient connection and fixing, good connection sealing effect and tight connection Effect

Active Publication Date: 2022-05-31

河北宝丰轻钢彩板有限责任公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a bending part structure for the assembly of container houses, so as to solve the problem that the connecting parts proposed in the above-mentioned background technology are fixed on the frame and cannot be moved, and there will be gaps between the connected plates, and the length Time is eroded by rainwater, which will cause the problem of loose connection between the connecting parts

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

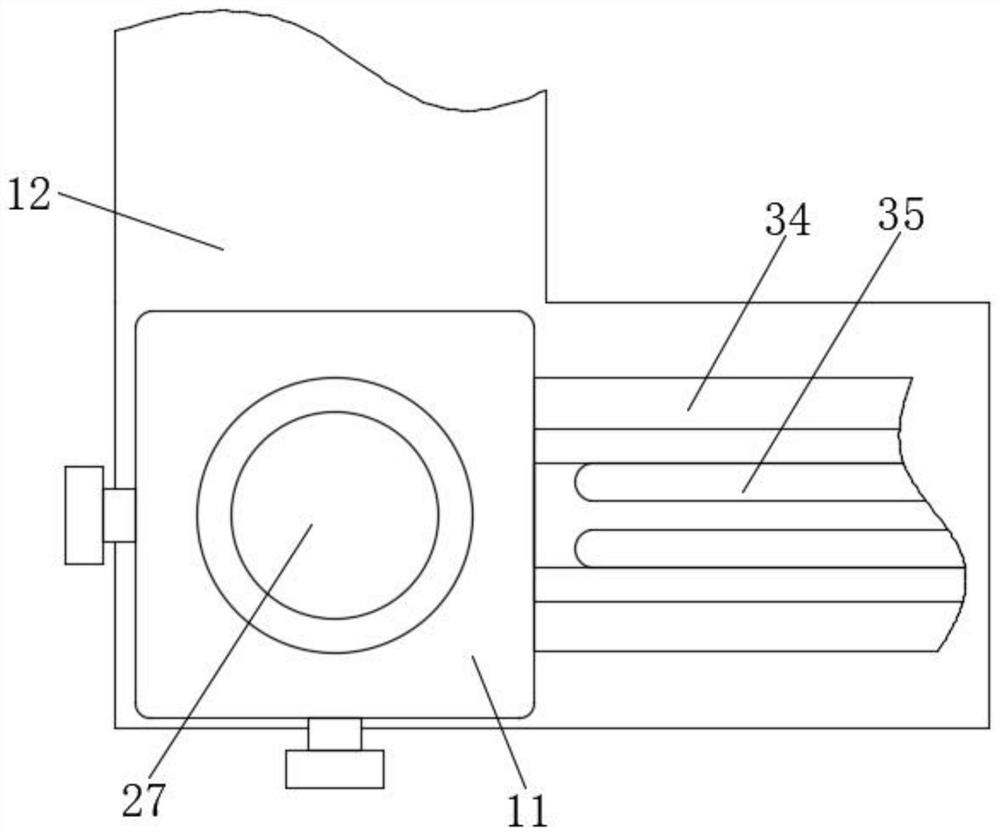

[0030] Through the rotation of the turntable 32, the gear 38 is rotated, and the support cylinder 37 supports the turntable 32.

[0031] It will be apparent to those skilled in the art that the invention is not limited to the details of the above-described exemplary embodiments, but also

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

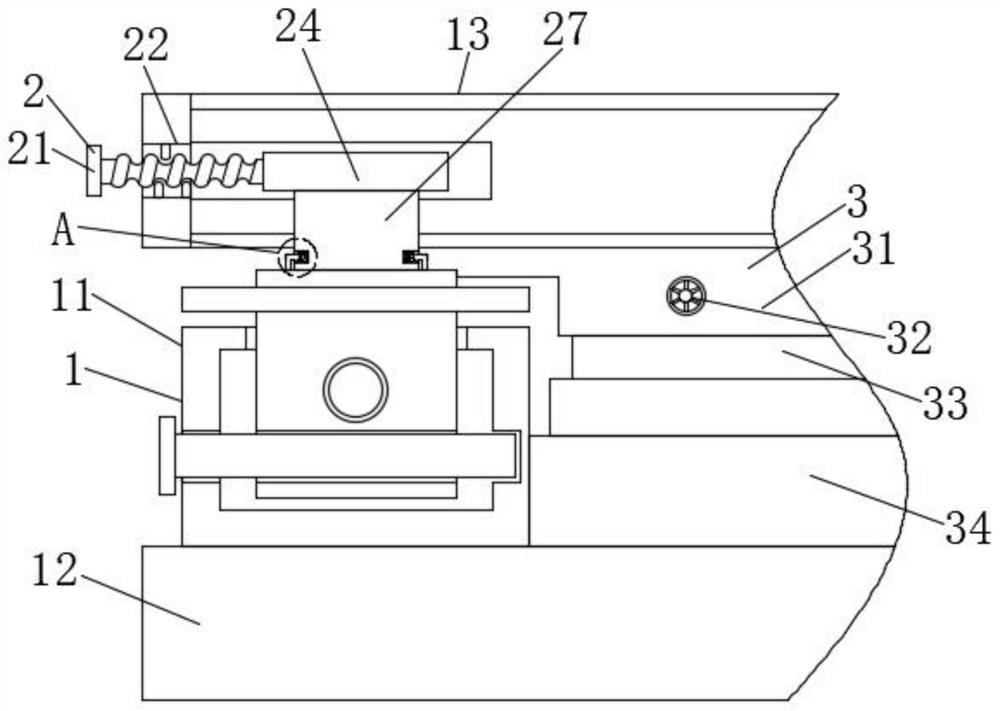

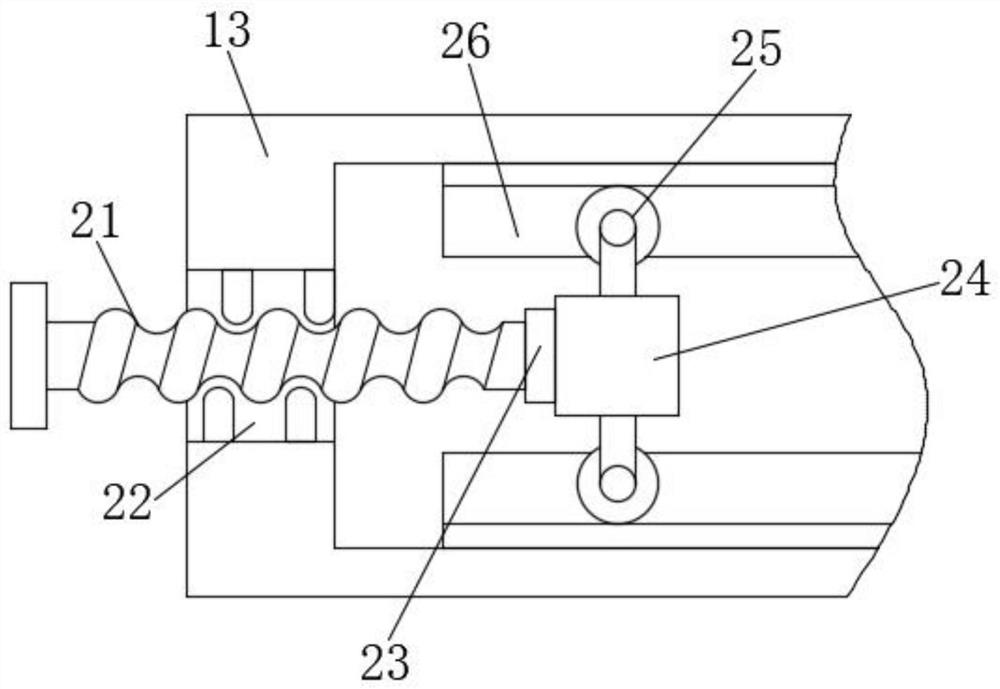

The invention relates to the technical field of container connection equipment, in particular to a bending part structure for container house assembly, including a plate body, the plate body includes a connecting cylinder, and the bottom end of the connecting cylinder is fixedly connected with a first connecting plate , the upper surface of the connecting cylinder is fixedly connected with a second connecting plate, the surface of the second connecting plate is provided with an adjustment mechanism, the adjusting mechanism includes an adjusting handle, and the surface of the second connecting plate is movably connected with an adjusting A rotating handle, the surface of the adjusting rotating handle is sleeved with a screw sleeve, the bottom end of the screw sleeve is movably connected with a rotating drum, and the surface of the rotating drum is fixedly connected with an adjusting block. The position of the connecting piece on the frame of the present invention can be moved, which is convenient for adjusting the position during installation, thereby facilitating its connection and fixing, and there is a sealing connecting plate on the connecting piece, which can realize the sealed connection between the connecting pieces and prevent rainwater from flowing through the frame. The inflow in the connection gap will cause corrosion to the connection parts.

Description

A bending part structure for container house assembly technical field The present invention relates to the technical field of container connection equipment, in particular to a kind of bending part structure used for the assembly of container houses. structure. Background technique Galvanized steel sheet is a welded steel sheet with hot-dip plating or electro-galvanized coating on the surface, and is generally widely used in construction, household appliances, automobiles, etc. Ship, container manufacturing and electromechanical industries, etc., galvanized steel plate is divided into ordinary electrolytic plate and anti-fingerprint electrolytic plate. On the basis of the electrolytic plate, a fingerprint-resistant treatment is added, which can resist sweat, and is generally used on parts without any treatment. [0003] The connection and fixing parts between the container houses are generally formed by bending galvanized steel sheets. It has the characteristics of c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): E04C2/08E04C2/30E04B1/61E04B1/68

CPCE04C2/08E04C2/30E04B1/61E04B1/68Y02A30/00

Inventor 李曼

Owner 河北宝丰轻钢彩板有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com