Hydraulic damper with external leakage preventing function

A technology of hydraulic damper and external leakage, which is applied in hydraulic and damping buffer, anti-seismic, and mechanical fields. It can solve the problems of hydraulic damper losing damping function, hydraulic damper oil leakage, and failure to work normally, so as to reduce the risk of external leakage, The effect of ensuring reliable operation and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

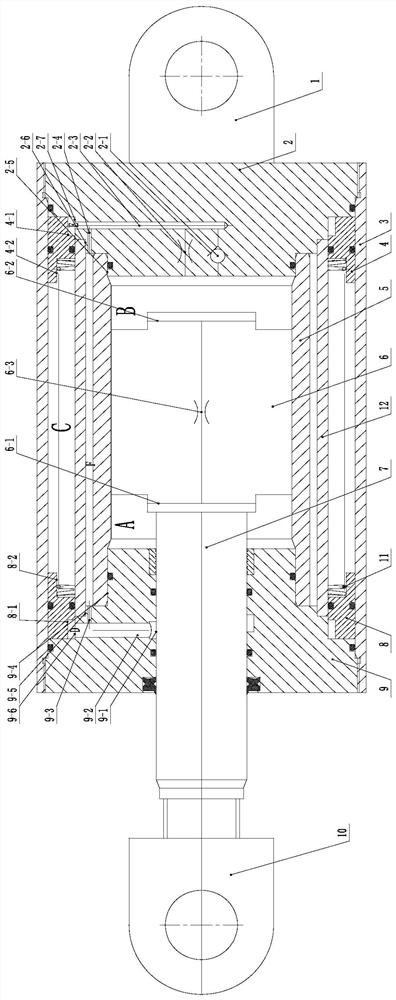

[0017] like figure 1 As shown, a hydraulic damper with the function of preventing external leakage, including the right pin head 1, the right end cover 2, the outer cylinder 3, the right piston 4 of the auxiliary oil tank, the inner cylinder 5, the damper piston 6, and the damper piston rod 7. Auxiliary fuel tank left piston 8, left end cover 9, left pin head 10, auxiliary fuel tank piston return spring 11 and middle cylinder 12;

[0018]The outer peripheral wall of the right end cover 2 is sequentially processed from left to right with the first step 2-5 of the right end cover, the second step 2-6 of the right end cover and the third step 2-7 of the right end cover, the third step of the right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com