Inter-axle differential mechanism structure

A technology of inter-axle differentials and differentials, applied in differential transmissions, belts/chains/gears, mechanical equipment, etc., can solve problems such as consumption, high cost of use, and poor fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

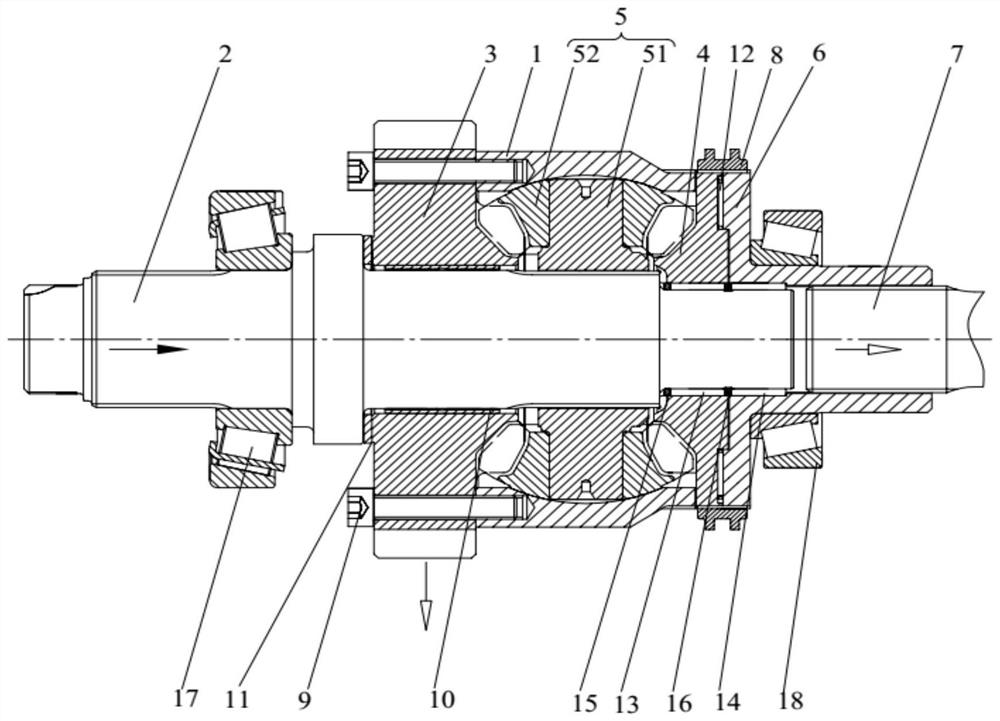

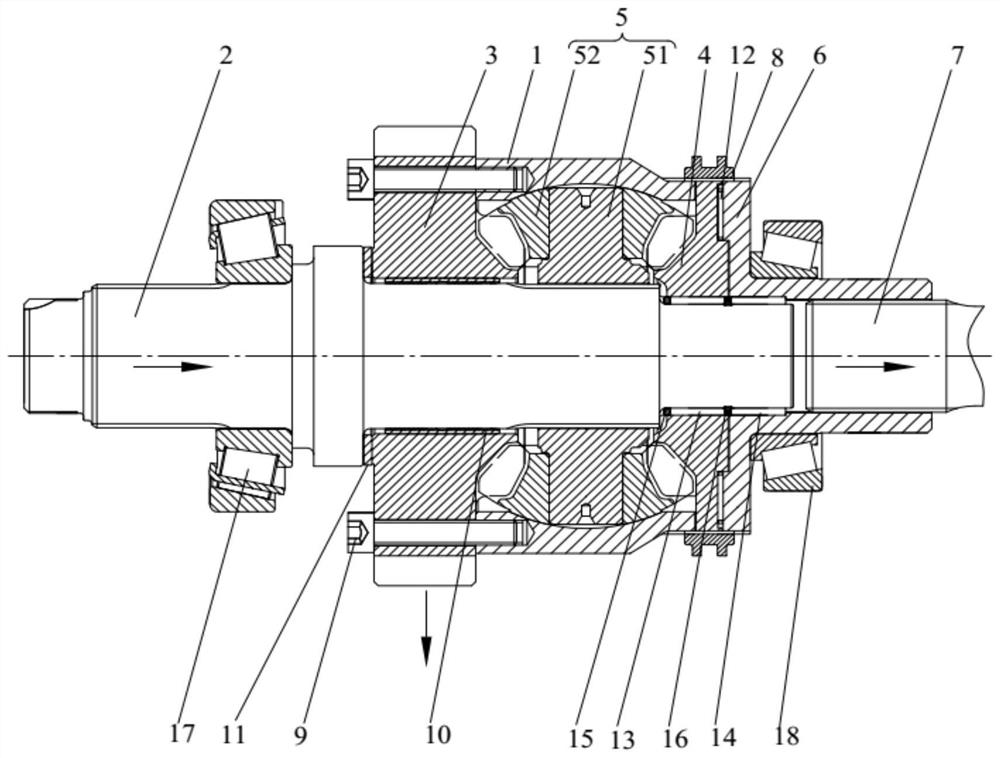

[0046] This embodiment provides an inter-axle differential structure, which is suitable for the field of automobile axles, especially the double-axle joint drive structure of the middle axle drive and the rear axle drive. Such asfigure 1 As shown, the structure of the inter-axle differential includes a differential housing 1, an input shaft 2, an output gear 3, a side gear 4, a transmission gear assembly 5, a bearing bracket 6, an output shaft 7 and a shift fork ring 8, and the differential The transmission housing 1 plays the role of overall support, and the input shaft 2 can also be called a cylindrical gear shaft. The input shaft 2 is passed through the differential housing 1, and the input shaft 2 is the input end of the torque. The output gear 3 is sheathed on the input shaft 2 and connected to one side of the differential case 1 . The output gear 3 is transmission connected to the middle axle, and the torque input from the input shaft 2 is transmitted to the middle axle t...

Embodiment 2

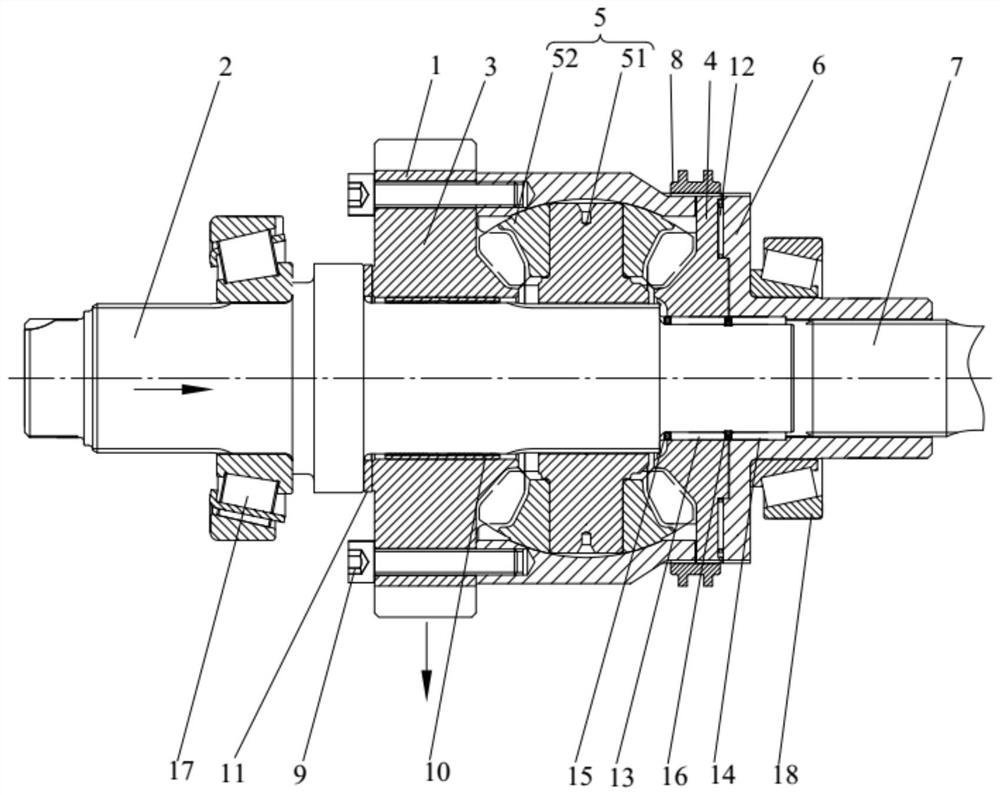

[0065] The structure and working principle of this embodiment and the first embodiment are generally similar, and the only difference lies in the connection mode between the output gear 3 and the differential case 1 . like Figure 4 As shown, in this embodiment, the output gear 3 is provided with a first connecting tooth, and the differential case 1 is provided with a second connecting tooth corresponding to the first connecting tooth, and the first connecting tooth and the second connecting tooth pass through The tooth-embedded structures 19 are connected together, and the first connecting tooth and the second connecting tooth are engaged with each other, and the fixing effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com