Single shot and running fire rubber band gun

A rubber band gun, burst technology, used in spring guns, weapons without explosives, offensive equipment, etc., can solve the problems of inability to launch, low remaining ammunition, prone to ricochet, double bullets, etc., to increase service life, Increase enjoyment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

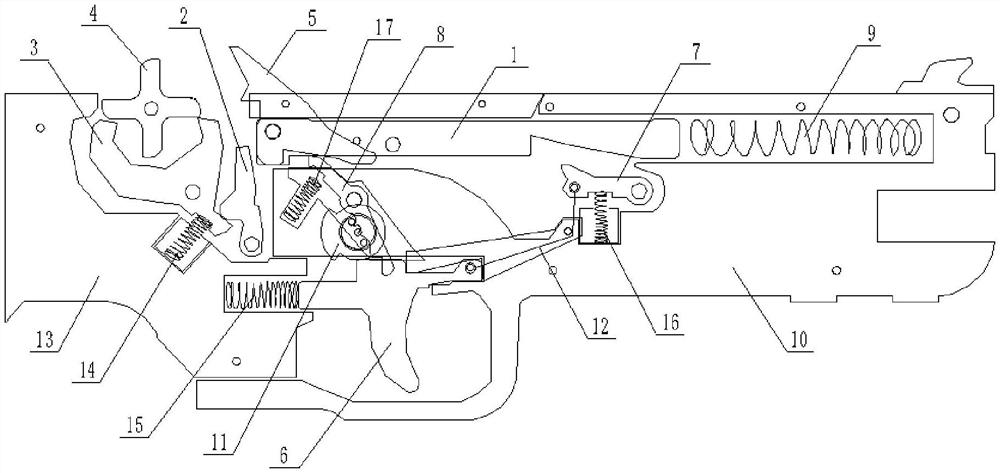

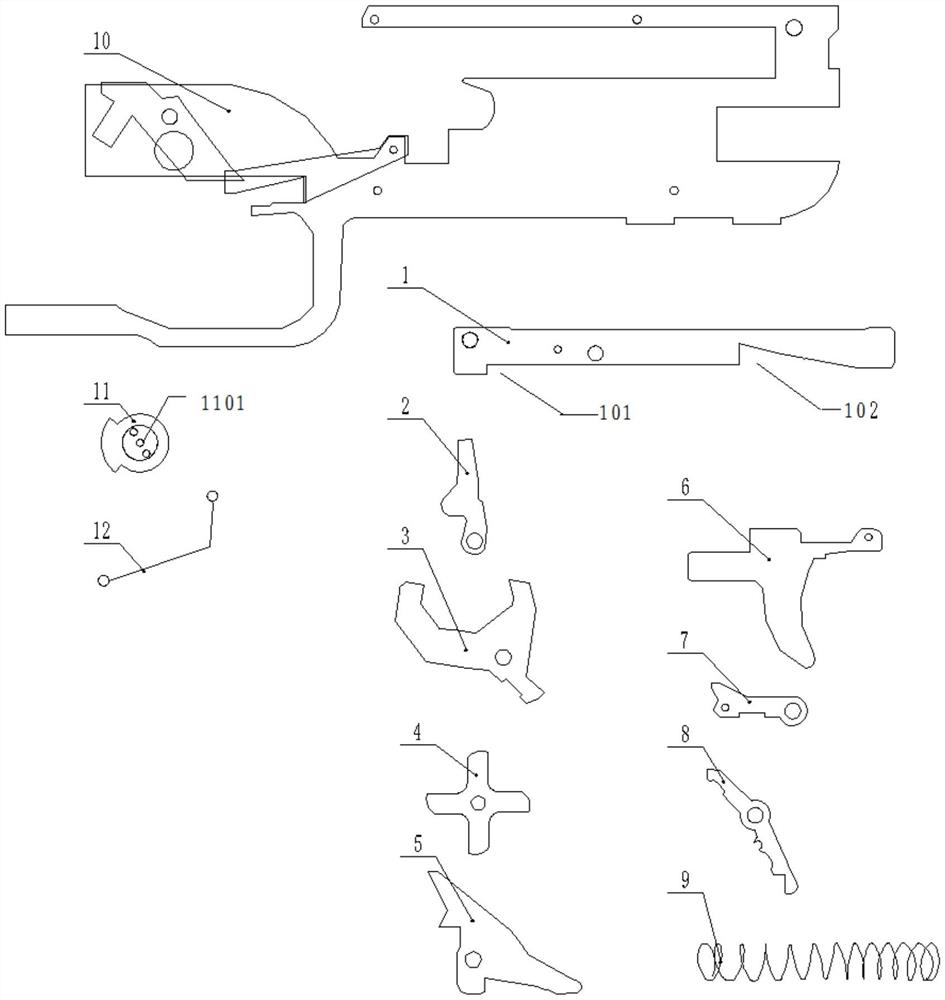

[0014] like Figure 1 to Figure 2 As shown, the present invention discloses a single burst rubber band gun, and the adopted technical solution includes a sliding pull bolt 1, a swing bumper 2, a gear release 3, a swing gear 4, a swing fin 5, a trigger 6, and a sliding pull bolt Stop buckle 7, single burst switching buckle 8, large pressure spring 9, gun core main board 10, single burst switching knob 11, excitation pull cord 12 and gun body tail 13; the sliding pull bolt 1 is placed on the gun core In the gun bore above the main board 10; a swing fin 5 with a stroke of 90 degrees is installed above the sliding pull bolt 1; the swing bump 2 is installed on the right side of the gear release 3 and contacts it; the gear release 3 Installed between the inner walls of the gun body tail 13; the swing gear 4 is installed between the inner walls of the gun body tail 13 and snapped into the gear release 3; the trigger 6 is installed below the gun barrel main board 10; the sliding pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com