Magnetic force loading device and loading method

A technology of loading device and magnetic force, applied in measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problem of inability to load, unsatisfactory force load simulation effect, and difficult to achieve the distribution density of loading points, etc. problem, to achieve the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

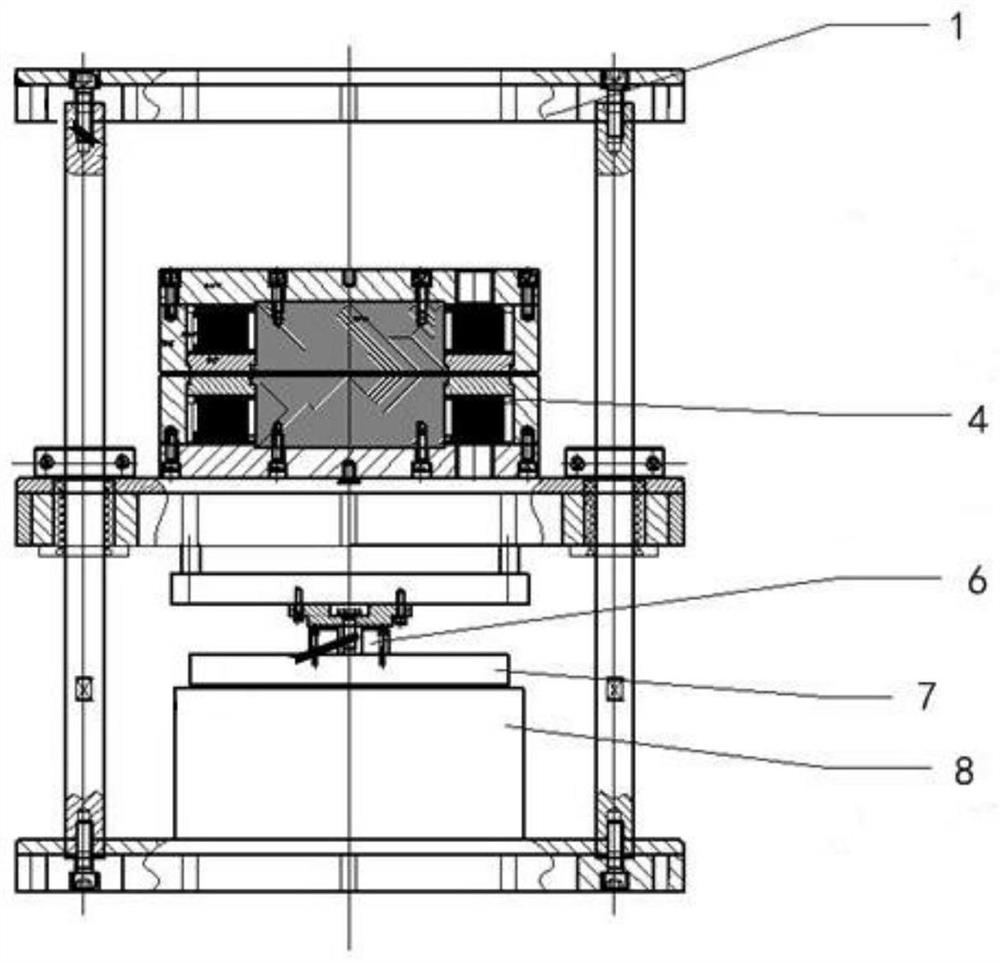

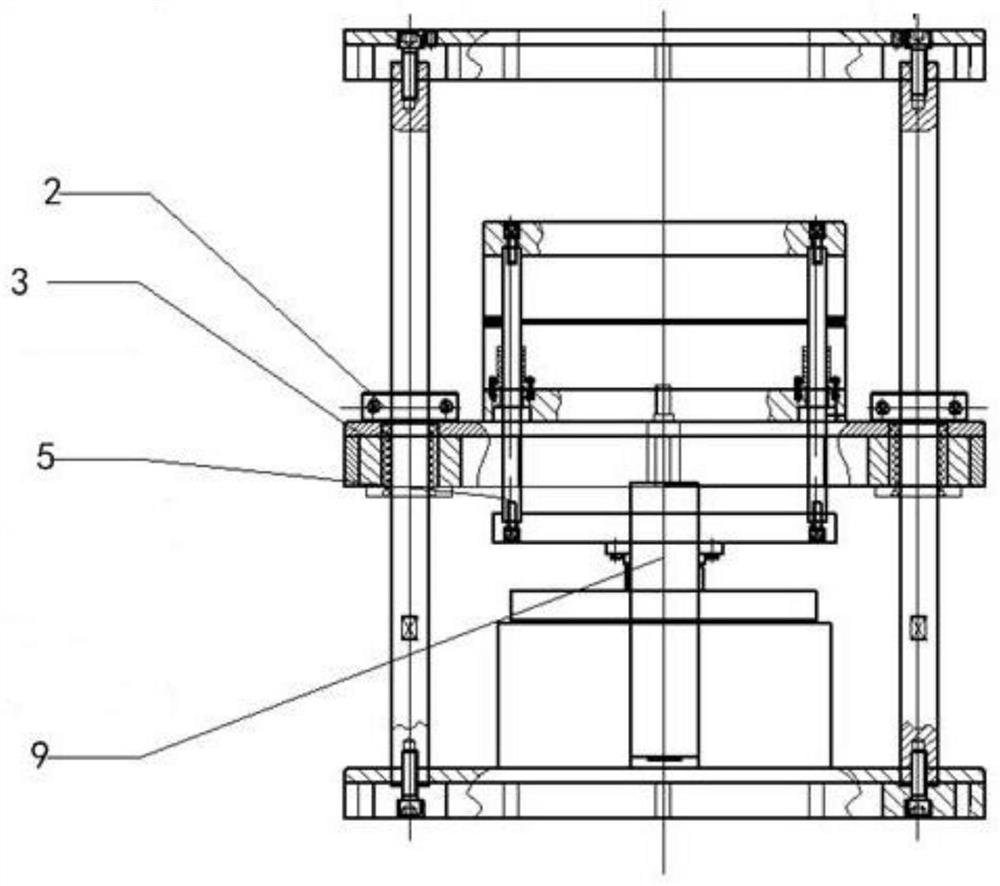

[0041] One embodiment of the present invention, magnetic loading device and loading method, such as Figure 1 to Figure 6 As shown, the magnetic loading device includes a mounting bracket 1 , a lifting platform 3 , a loading system 4 , a connecting guide device 5 , a tooling 7 , a test piece platform 8 and a lifting device 9 .

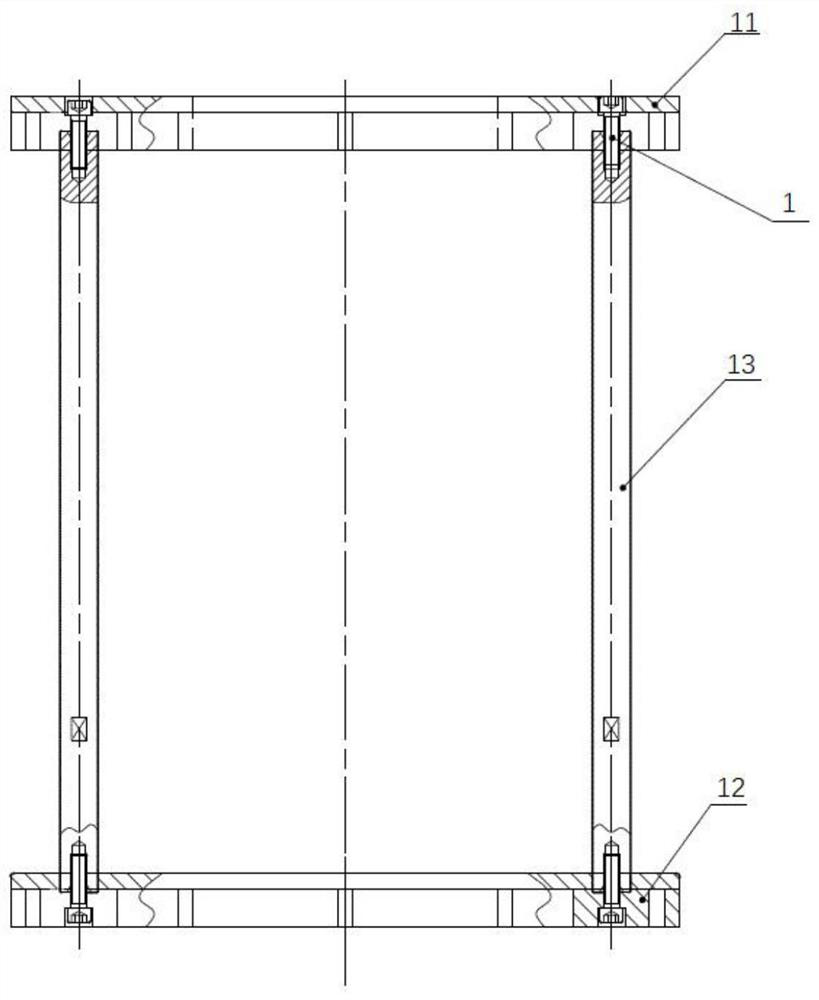

[0042] The mounting bracket 1 includes an upper plate 11, a lower plate 12 and a column 13. The mounting bracket 1 provides support for the magnetic force loading device, fixes the entire magnetic force loading device, carries the suction force between the electromagnets during the test, and serves as a motion guide for the lifting platform 3 , to facilitate the up and down movement of the lifting platform 3. Exemplarily, the upper plate 11 and the lower plate 12 are square plates. The lower plate 12 provides support for the entire magnetic loading device, and at the same time, the lower plate 12 provides an installation platform for the test piece pl...

Embodiment 2

[0062] In order to further verify the magnetic loading device of this embodiment, a verification test of the magnetic loading device was carried out for a C / SiC test piece with a size of 400×400×3 mm, and the force value and voltage and current data were recorded and analyzed. Specific steps include:

[0063] Step 1. Raise the lifting platform and install the test piece:

[0064] Loosen the locking screw of the locking device 2, and inflate the cylinder of the lifting device 9 through the three-dimensional five-way valve, so that the cylinder drives the lifting platform 3 and the loading system 4 on the lifting platform 3 to slowly rise along the column 13 of the mounting bracket 1 to The highest position, and then put a 400×400×3mm C / SiC test piece on the test piece platform 8 .

[0065] Step 2. Fixed loading system:

[0066] The cylinder of the lifting device 9 is deflated through the three-dimensional five-way valve, so that the cylinder drives the lifting platform 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com