PWM modulation method and system for multi-module motor, vibration and common mode current suppression

A modulation method and common mode current technology, applied in control systems, current controllers, motor control, etc., to achieve the effects of reducing vibration noise, high power density, and suppressing common mode currents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

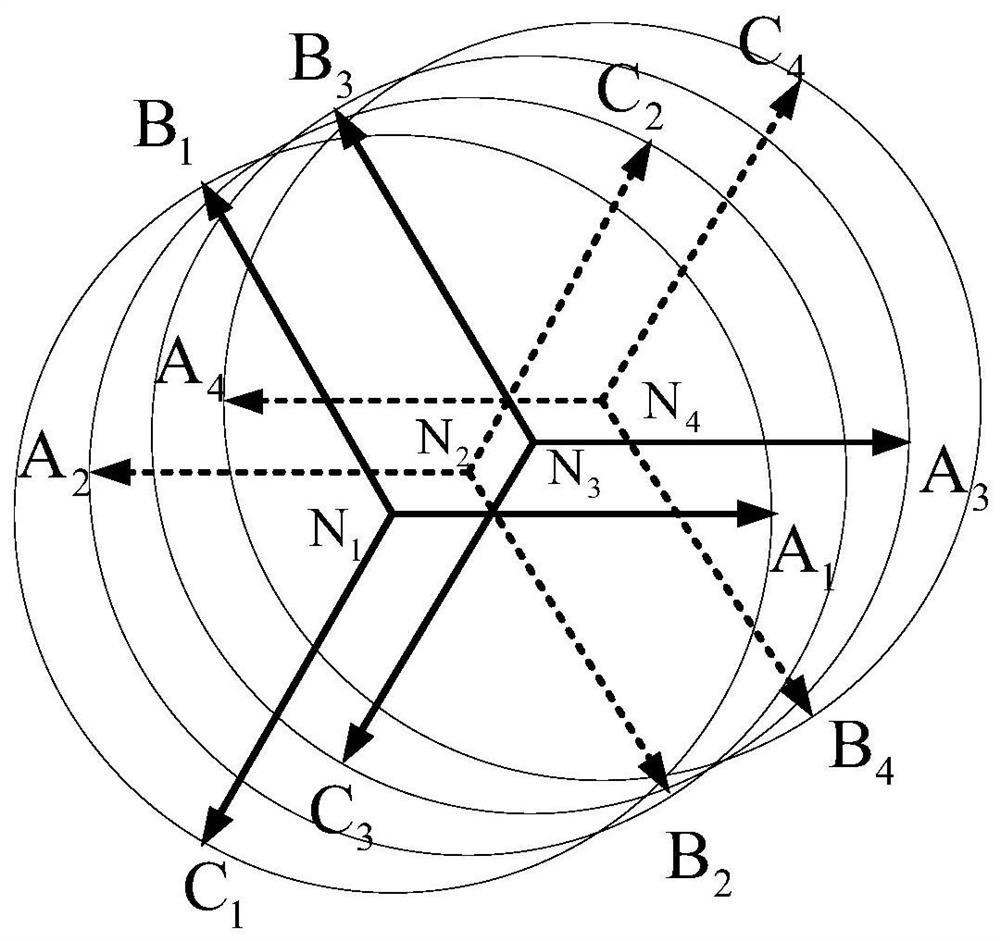

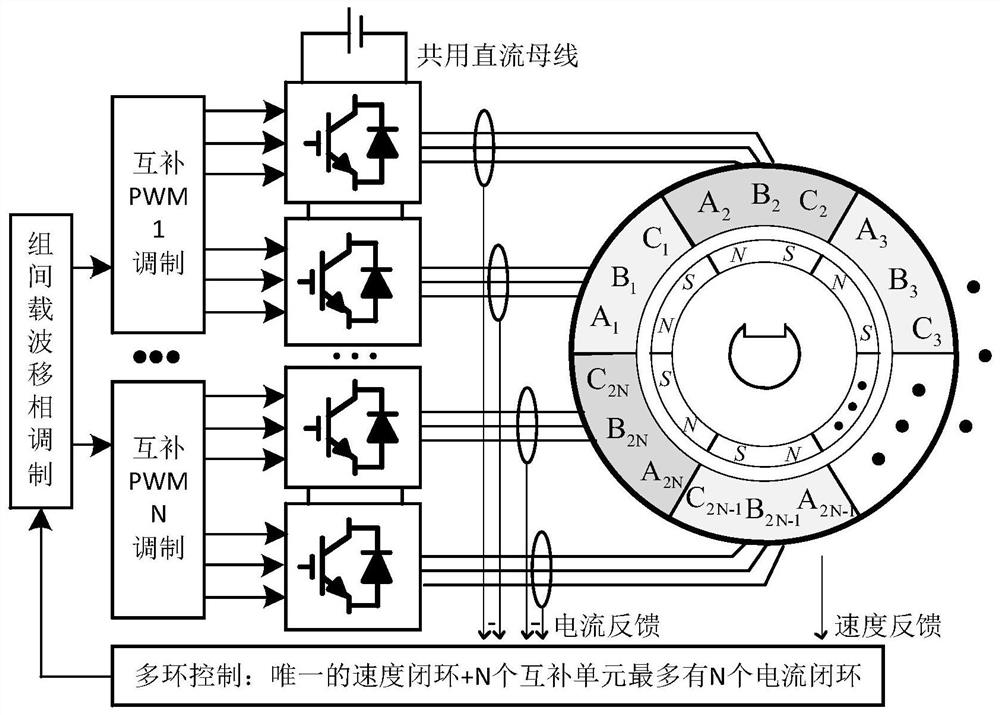

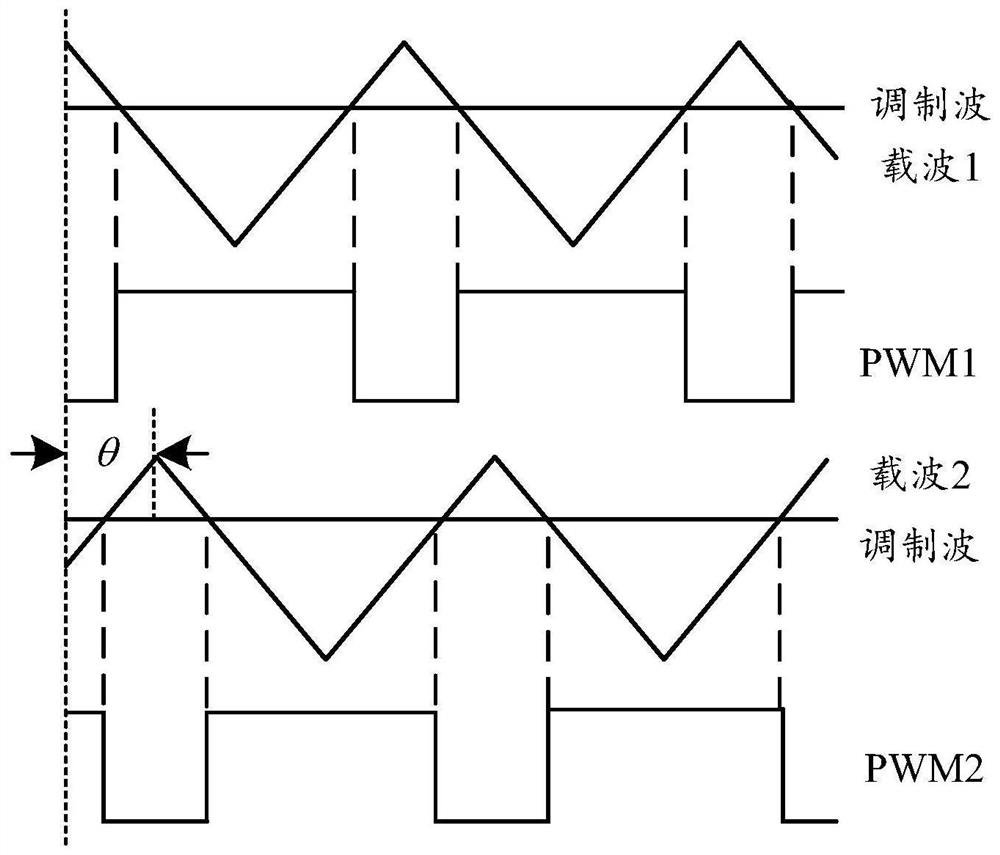

[0037] The invention proposes a multi-module motor, the stator of which is composed of an even number of Y-connected three-phase windings, each set of windings has the same impedance, and the neutral points are not connected to each other, here it is expressed as 2N sets of three-phase windings, and N is greater than 2 positive integer. There is very little magnetic circuit coupling between each set of windings, which avoids the increase of winding current ripple caused by the circulating current after carrier phase shifting, so the coupling inductance is unnecessary.

[0038] From a structural po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com