Camera module pressure test structure

A camera module and stress testing technology, which is applied in image communication, television, electrical components, etc., can solve the problems of cumbersome operation and low efficiency, and achieve high test accuracy, convenient use, and accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

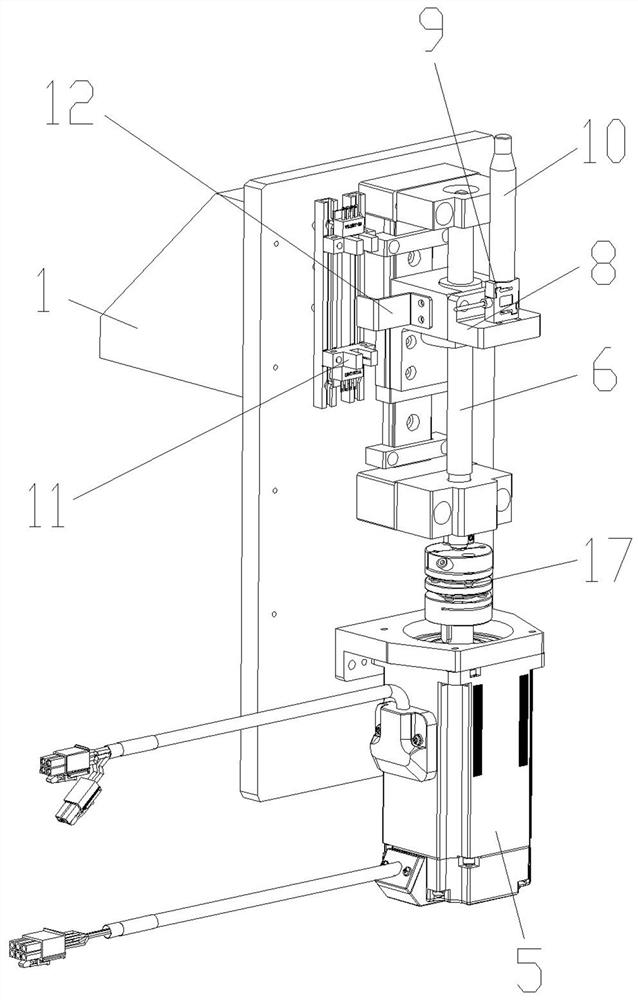

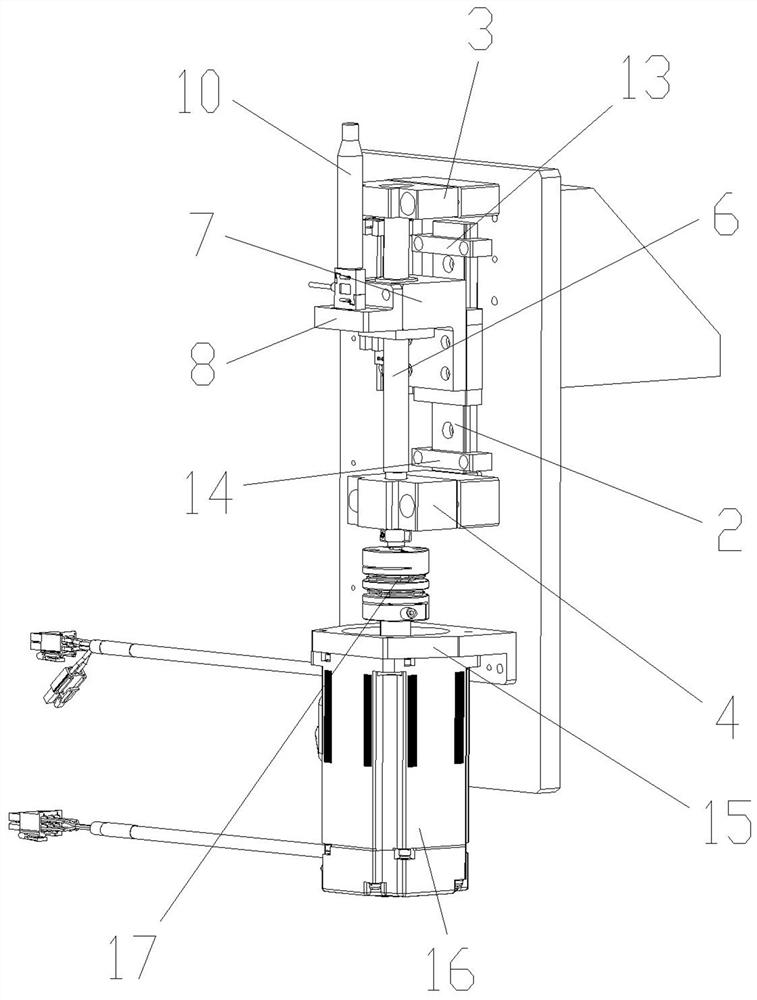

[0013] Such as Figure 1 to Figure 2 As shown, in this embodiment, the present invention includes a mounting seat 1, on which a guide rail assembly 2, an upper bearing seat 3, a lower bearing seat 4 and a drive module 5 are arranged, and the upper bearing seat 3 and A threaded mandrel 6 is cooperatingly arranged between the lower bearing seats 4, a threaded mandrel seat 7 is slidably arranged on the guide rail assembly 2, the threaded mandrel 6 is arranged on the said threaded mandrel seat 7, and on the said threaded mandrel 6 A top block 8 is provided, and a pressure sensor 9 is provided on the top block 8 , and a thimble 10 is provided on the pressure sensor 9 , and the driving module 5 is in transmission cooperation with the screw rod 6 . Compared with the deficiencies of the prior art, in the present invention, during the test, the screw rod 6 drives the jack block 8 to move upward through the drive module 5, so that the upper end of the ejector pin 10 can be fixed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com