A braking hose pneumatic fixed pressure detection test machine

A brake hose and testing machine technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the pollution of the surrounding environment, waste of manpower and material resources, and low detection accuracy problem, to achieve the effect of good blockage and pressure resistance, accurate pressure test and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 Brake hose air pressure constant pressure detection test machine equipment composition and the role of each component:

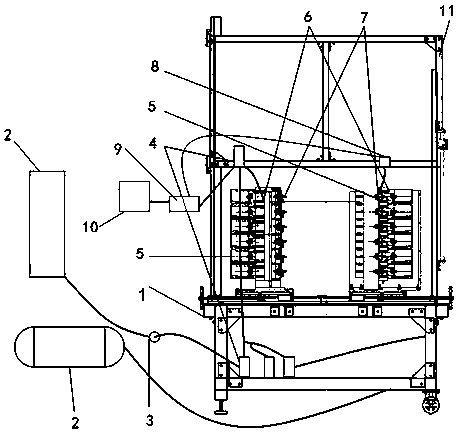

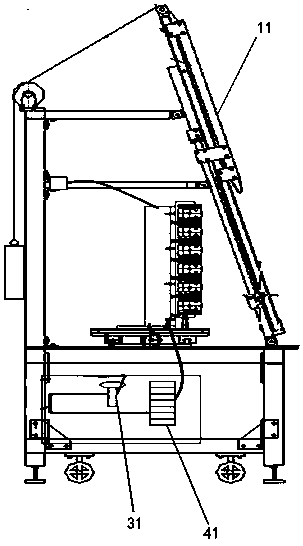

[0025] The present invention proposes a brake hose air pressure constant pressure testing machine, which includes a main frame 1, a filter 3, a solenoid valve device 4 and a safety door 11 device, and is characterized in that the testing machine also includes: an air source 2, a test Component supporting device 5, cylinder 6, pressure measuring joint 7, pressure sensor 8 and PLC control system 9; air source 2 is connected to cylinder 6 through filter 3 and solenoid valve 4 to provide test medium for the testing machine, and the test medium is compressed gas ; The cylinder 6 is arranged on the test piece support device 5, and is installed at one end of the pressure measuring joint 7. When the testing machine detects, both ends of the test hose are connected to the pressure measuring joint; the pressure sensor 8 is installed on the cylinder 6, ...

Embodiment 2

[0033] Example 2 The working process of the brake hose air pressure constant pressure detection test machine:

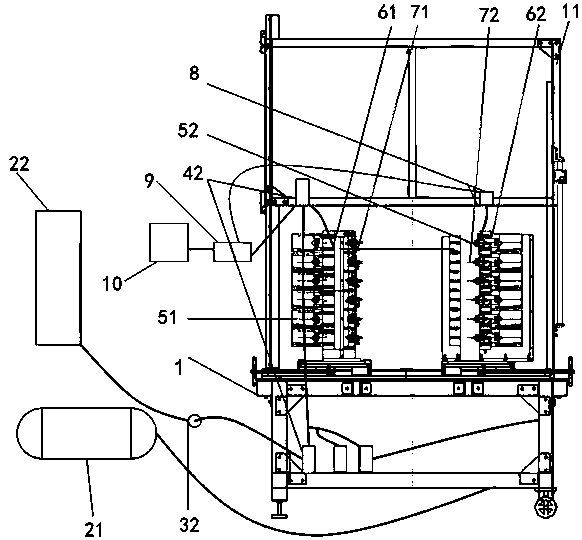

[0034]Connect the low-pressure air source 21, high-pressure air source 22 and power supply, open the air source valve, and turn on the power switch, so that the high-pressure air source 22 reaches the high-pressure solenoid valve 42 after being filtered by the high-pressure filter 32, so that the low-pressure air source 21 is filtered by low pressure After being filtered by the filter 31, it reaches the low-pressure solenoid valve 41; adjust the rotating and detachable clamp locking device of the pressure measuring joint 7 to suit the hose to be tested, check whether the pressure measuring joint 7 is in good condition, and manually operate to check whether each action is in place , confirm that all parts are ready correctly, and then select the automatic operation state on the touch screen 10 of the man-machine interface; fix the test piece through the action of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com