Fpcb assembly for battery module, method for manufacturing same, and battery module comprising same

A battery module and circuit board assembly technology, applied in battery pack components, printed circuit manufacturing, circuit bendable/stretchable components, etc., can solve problems such as increased material cost and achieve the effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, preferred embodiments of the present disclosure will be described in detail with reference to the accompanying drawings. Before the description, it should be understood that the terms used in the specification and appended claims should not be construed as limited to the ordinary and dictionary meanings, but on the basis of the principle of allowing the inventor to define the terms appropriately to obtain the best explanation Interpretation is based on meanings and concepts corresponding to technical aspects of the present disclosure.

[0035] Therefore, the descriptions presented herein are only for illustrative preferred examples and are not intended to limit the scope of the present disclosure, so it should be understood that other equivalents and Revise.

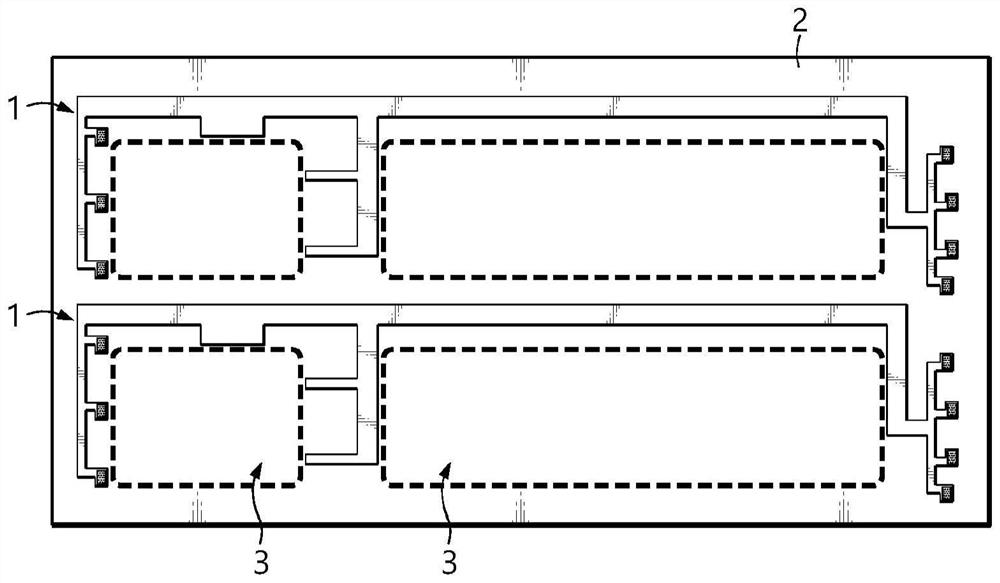

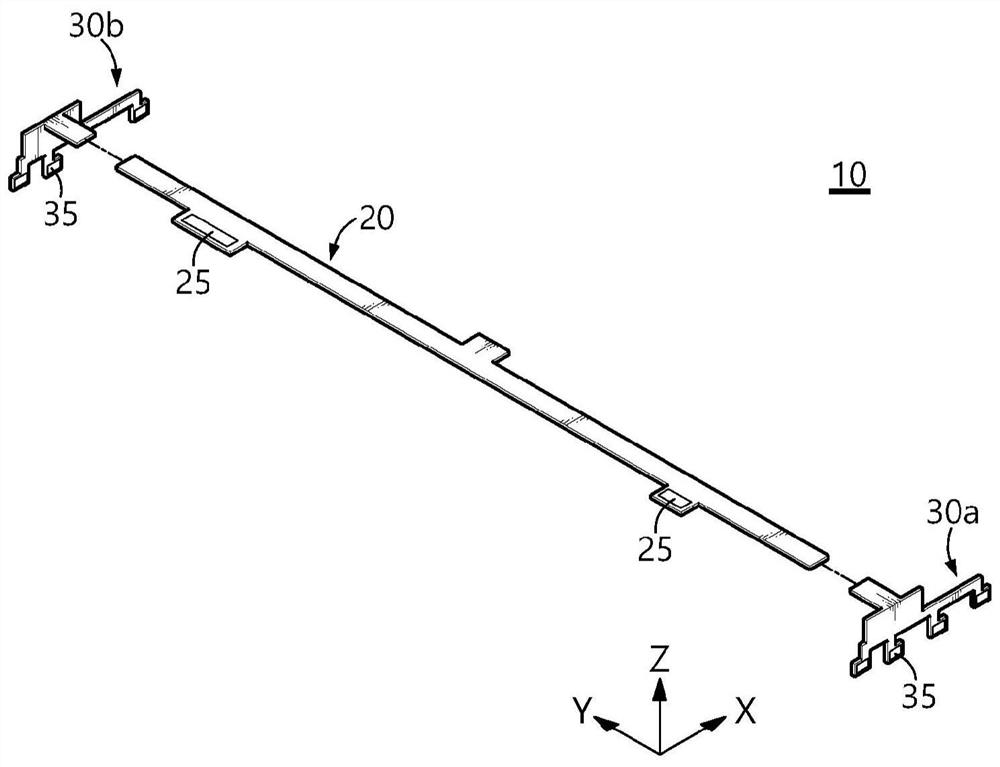

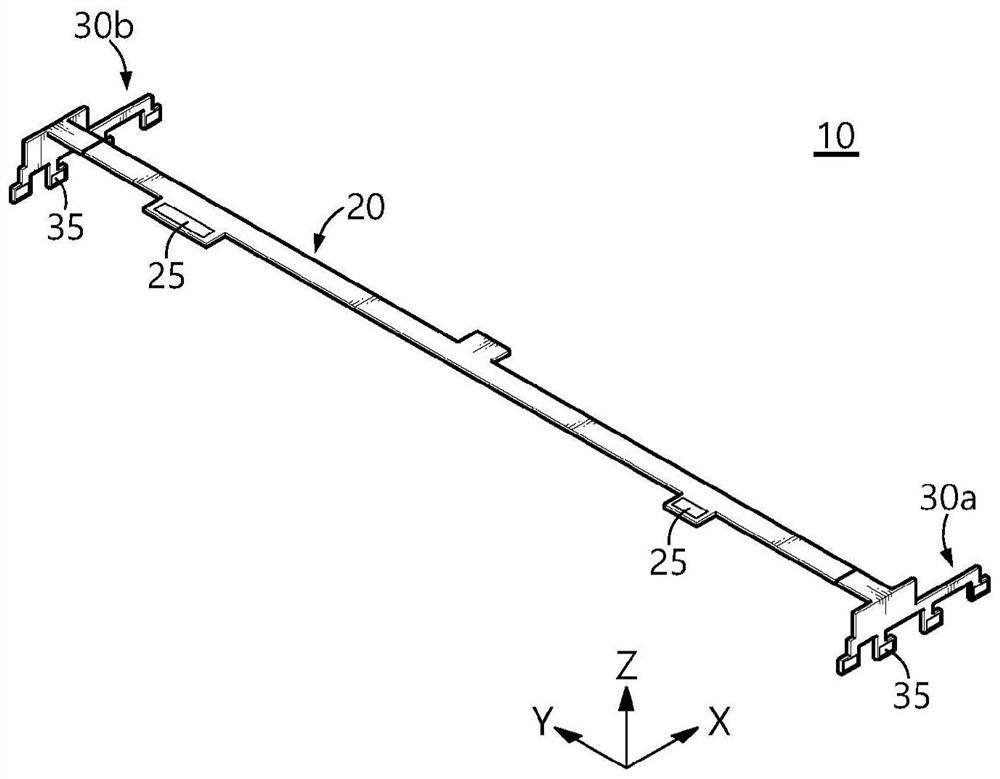

[0036] The FPCB assembly described below may be included in a battery module and used as a wiring part that senses voltage and temperature of a secondary battery cell and transmits the voltage and te...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap