Method for adjusting ice cream machine stirring speed and ice cream hardness and ice cream machine

A stirring speed, ice cream machine technology, applied in frozen sweets, food science, applications, etc., can solve the problems of slow ice cream stirring speed, stalling, and non-adjustable speed of ice cream stirring, so as to improve the quality and taste, and expand the scope of functions , the effect of reasonable air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0031] see Image 6 , the invention discloses a method for adjusting the stirring speed of an ice cream machine and the hardness of ice cream, comprising the following steps:

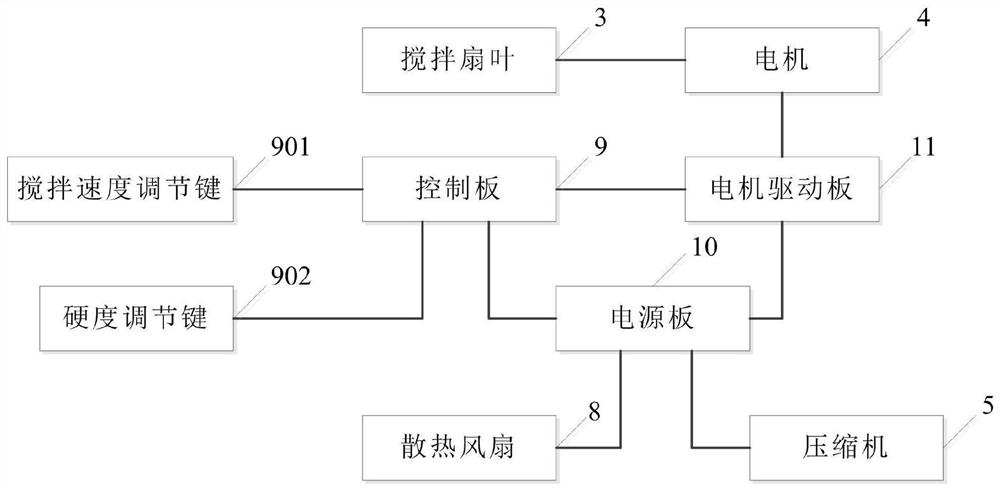

[0032] S601. The control board receives the target stirring speed and the target hardness of the ice cream respectively set by the user through the stirring speed adjustment key and the hardness adjustment key;

[0033] In the embodiment of the present invention, the above-mentioned control panel is provided with an operation panel, and the stirring speed adjustment key and the hardness adjustment key are arranged on the operation panel. The stirring speed adjustment key and the hardness adjustment key here can be push-type adjustment keys or touch The adjustment key is not limited in this embodiment; the user can set the target stirring speed and the target hardness of the ice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com