A shot blasting machine

A technique of polishing machine and shot blasting, which is applied in the direction of abrasive jetting machine tools, metal processing equipment, used abrasive processing devices, etc., and can solve problems affecting machine operation and service life, machine dust accumulation, and damaged metal shots, etc., to achieve Clean and effective, fast transportation, and improved linkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

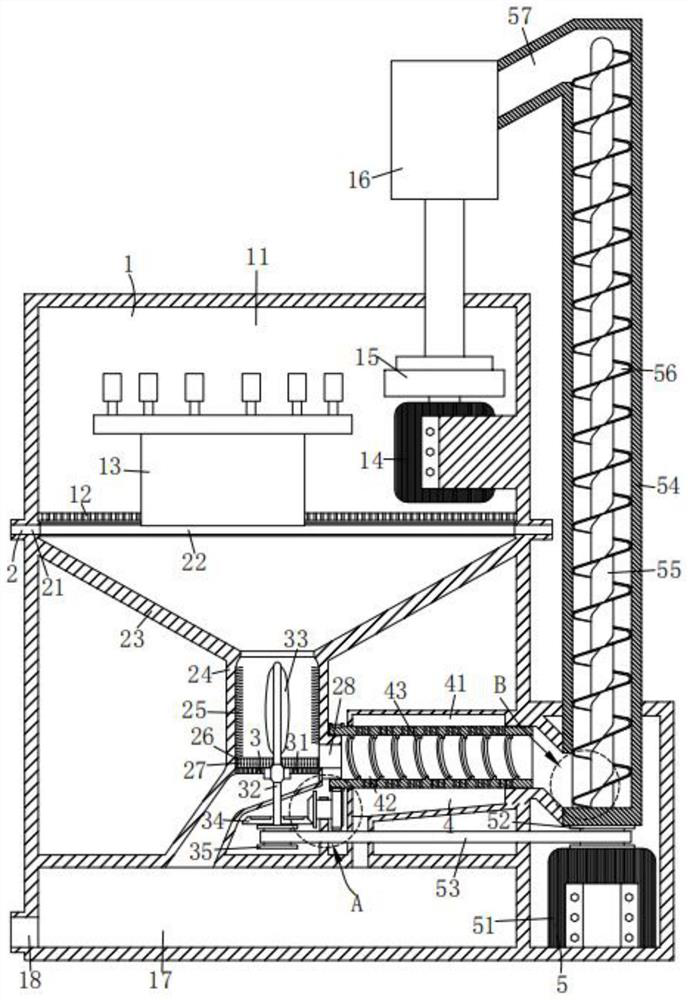

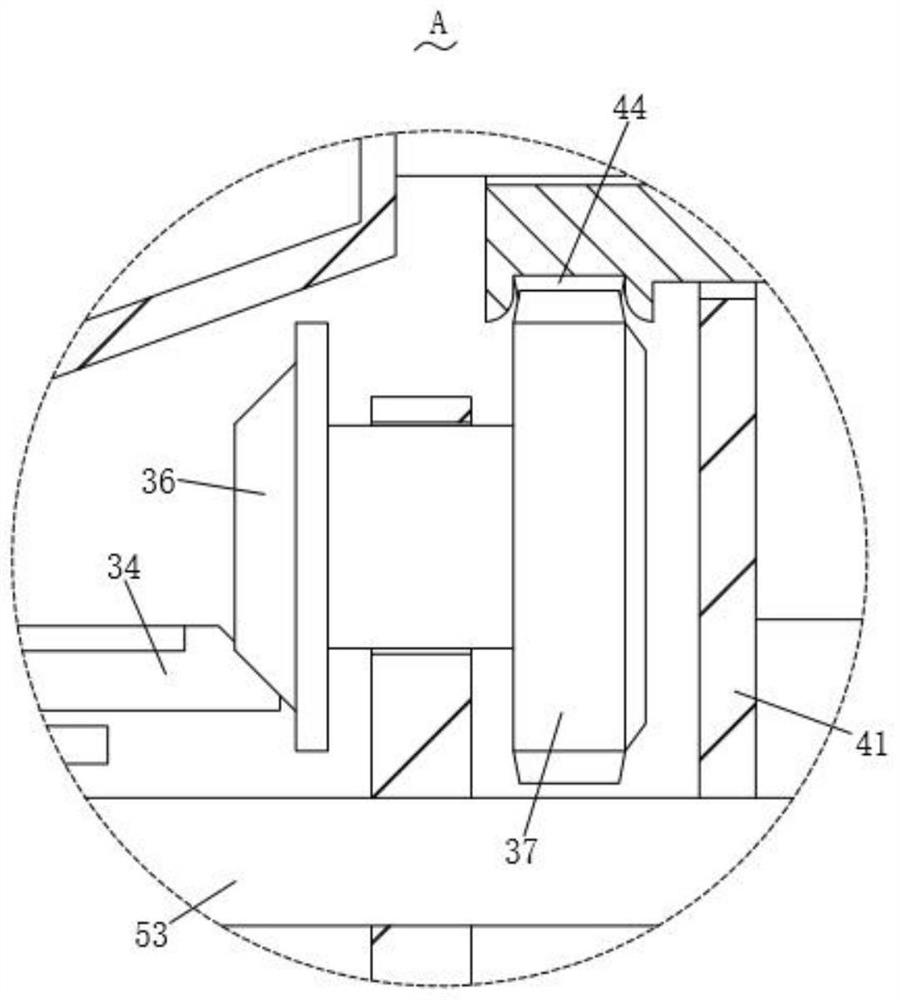

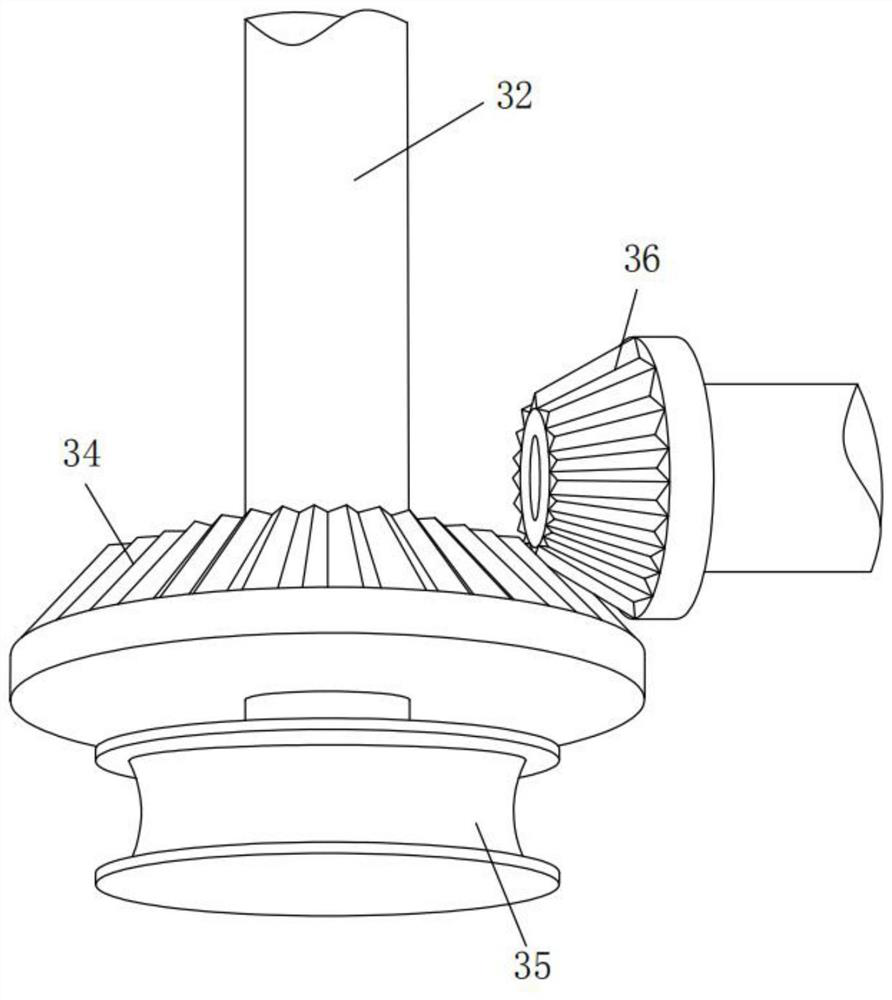

[0024] Such as Figure 1-Figure 5 As shown, a kind of shot blasting machine of the present invention comprises body structure 1, cleaning structure 2, rotating structure 3, dehydration structure 4 and collection structure 5; Inside the body structure 1; the body structure 1 for processing workpieces is connected with the collection structure 5; the water for driving the cleaning structure 2 to rotate and the dehydration structure 4 to rotate The rotating structure 3 is rotatably connected to the inside of the cleaning structure 2; the dehydration structure 4 for drying and transporting the metal shot is rotatably connected with the cleaning structure 2 and the rotating structure 3; it is used for transporting the metal shot, allowing the metal Th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap