Combined heat exchanger, heat exchange system and optimization method thereof

A technology of heat exchange system and heat exchange unit, applied in the field of heat exchange system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

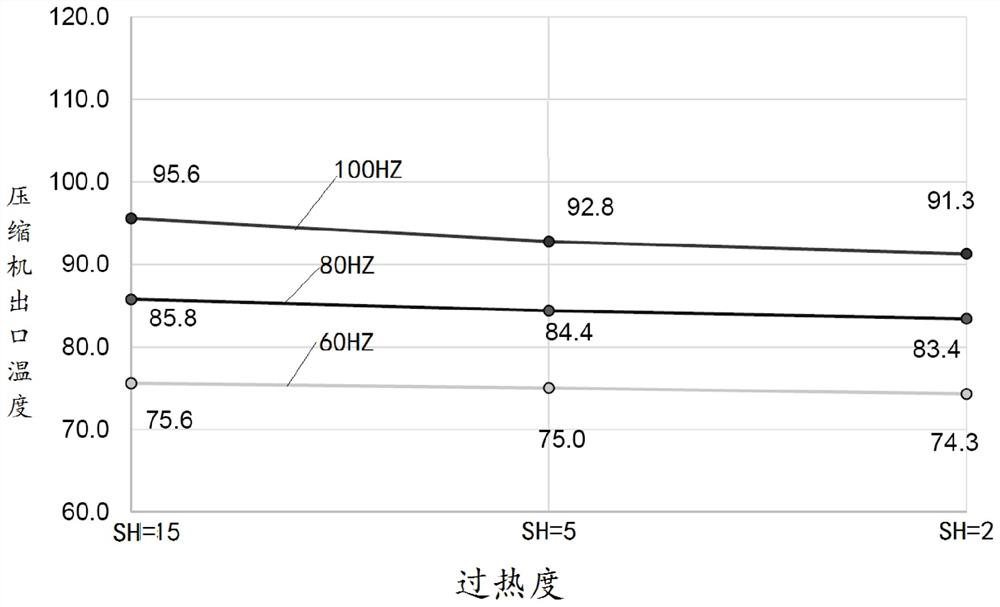

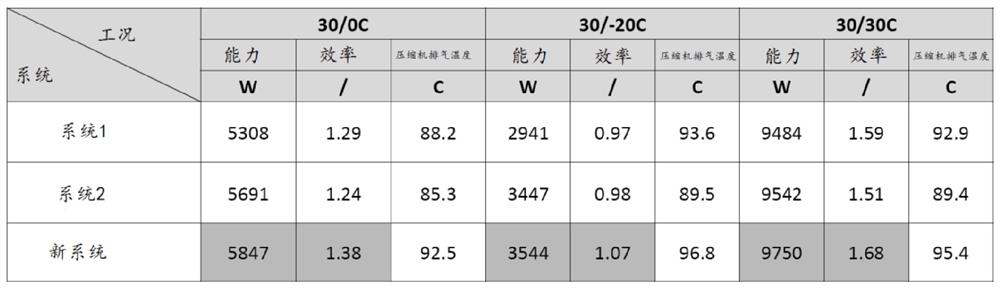

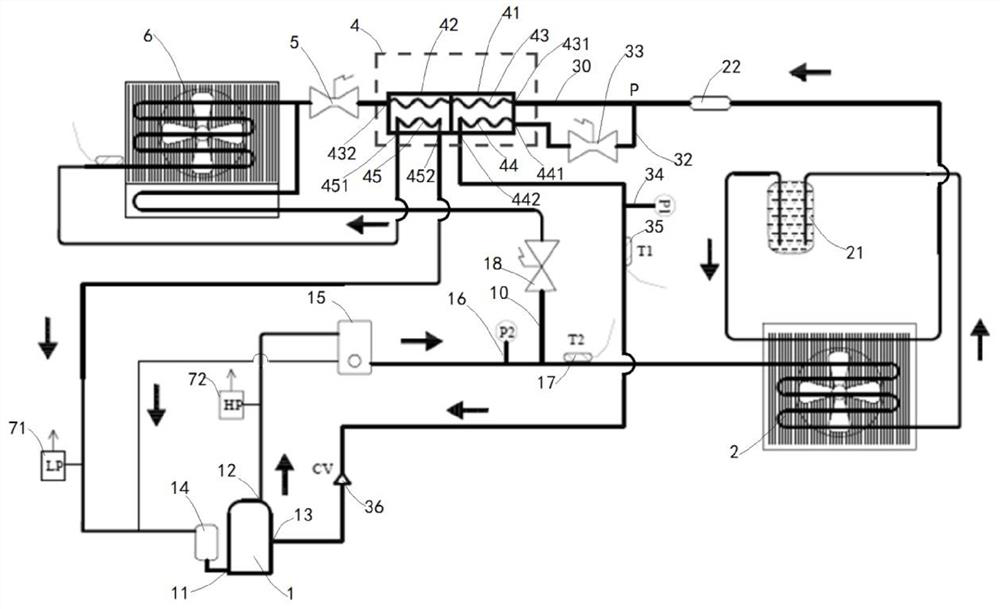

[0035] first reference figure 1 Let’s introduce the heat exchange system according to the embodiment of the present invention. This system can be used in various working conditions, especially for the refrigeration system of electric transport vehicles. sensitive. The heat exchange system includes: a steam enthalpy injection compressor 1 , a condenser 2 , an expansion valve 5 and an evaporator 6 in the main loop. The steam enthalpy injection compressor 1 includes a compressor inlet 11 , a compressor outlet 12 and a steam enthalpy injection port 13 . As shown in the figure, the high-temperature and high-pressure steam leaving the compressor outlet 12 of the heat exchange system passes through the oil separator 15 to separate the oil, and then returns to the compressor inlet 11 through the oil return pipe and the gas-liquid separator 14, while the refrigerant enters the condensation After leaving the condenser 2, the refrigerant passes through the liquid storage drier 21 and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com