Production method for producing metformin hydrochloride

A technology of metformin hydrochloride and a production method, which is applied in the directions of organic chemistry methods, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of low yield, increased production cost, low purity of metformin hydrochloride impurities, and impact on the quality of metformin hydrochloride finished products, etc. problems, to achieve the effect of improving quality and yield, reducing impurities and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

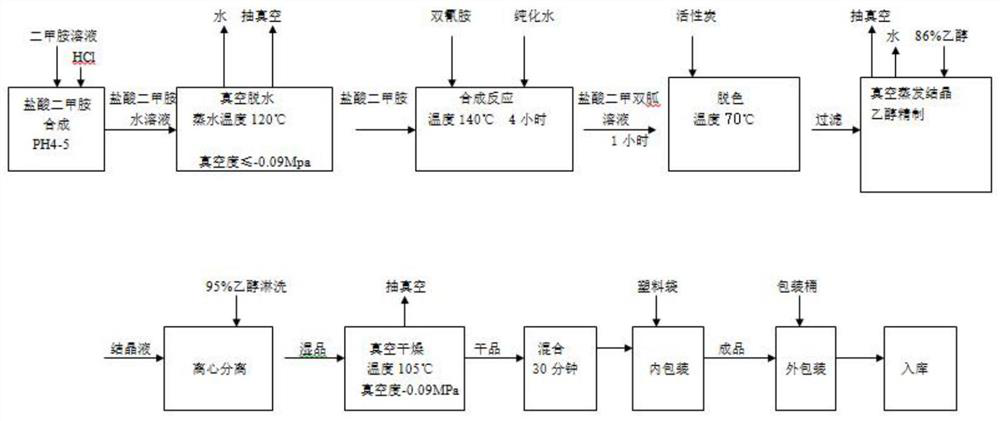

[0031] refer to figure 1 , a production method for producing metformin hydrochloride, comprising the synthesis, crystallization and refining of metformin hydrochloride crude product.

[0032] The synthesis of metformin hydrochloride crude product comprises the following steps: pump the dimethylamine hydrochloride solution in the salt forming tank into the synthesis tank through vacuum, evaporate the material to dryness at 120°C, then add 600kg of dicyandiamide, control the steam at ≥0.4Mpa, and the reaction temperature 140°C, react for 4 hours, pass circulating water to cool down to 105°C, add 2500kg of purified water, heat to 50°C, keep stirring for 1 hour, and let stand for 30 minutes.

[0033] The preparation of dimethylamine hydrochloride solution comprises the following steps: add 920 kg of dimethylamine into the dimethylamine hydrochloride salt forming tank through the dimethylamine metering tank, cool the temperature of the tank interlayer with cold brine, start stirrin...

Embodiment 2

[0049] refer to figure 1 , a production method for producing metformin hydrochloride, comprising the synthesis, crystallization and refining of metformin hydrochloride crude product.

[0050] The synthesis of metformin hydrochloride crude product comprises the following steps: pump the dimethylamine hydrochloride solution in the salt forming tank into the synthesis tank through vacuum, evaporate the material to dryness at 120°C, then add 600kg of dicyandiamide, control the steam at ≥0.4Mpa, and the reaction temperature 140°C, react for 4 hours, pass circulating water to cool down to 105°C, add 2500kg of purified water, heat to 50°C, keep stirring for 1 hour, and let stand for 30 minutes.

[0051]The preparation of dimethylamine hydrochloride solution comprises the following steps: add 920 kg of dimethylamine into the dimethylamine hydrochloride salt forming tank through the dimethylamine metering tank, cool the temperature of the tank interlayer with cold brine, start stirring...

Embodiment 3

[0067] refer to figure 1 , a production method for producing metformin hydrochloride, comprising the synthesis, crystallization and refining of metformin hydrochloride crude product.

[0068] The synthesis of metformin hydrochloride crude product comprises the following steps: pump the dimethylamine hydrochloride solution in the salt forming tank into the synthesis tank through vacuum, evaporate the material to dryness at 120°C, then add 600kg of dicyandiamide, control the steam at ≥0.4Mpa, and the reaction temperature 140°C, react for 4 hours, pass circulating water to cool down to 105°C, add 2500kg of purified water, heat to 50°C, keep stirring for 1 hour, and let stand for 30 minutes.

[0069] The preparation of dimethylamine hydrochloride solution comprises the following steps: add 920 kg of dimethylamine into the dimethylamine hydrochloride salt forming tank through the dimethylamine metering tank, cool the temperature of the tank interlayer with cold brine, start stirrin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap