Egg tray forming and drying method

A technology of egg tray and drying chamber, which is applied in the direction of textiles and papermaking, etc., can solve the problems of affecting the yield rate, high drying cost, and long time, and achieve the effect of simple drying method, guaranteed drying efficiency, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and technical solutions, and the implementation of the present invention will be described in detail through preferred embodiments, but the implementation of the present invention is not limited thereto.

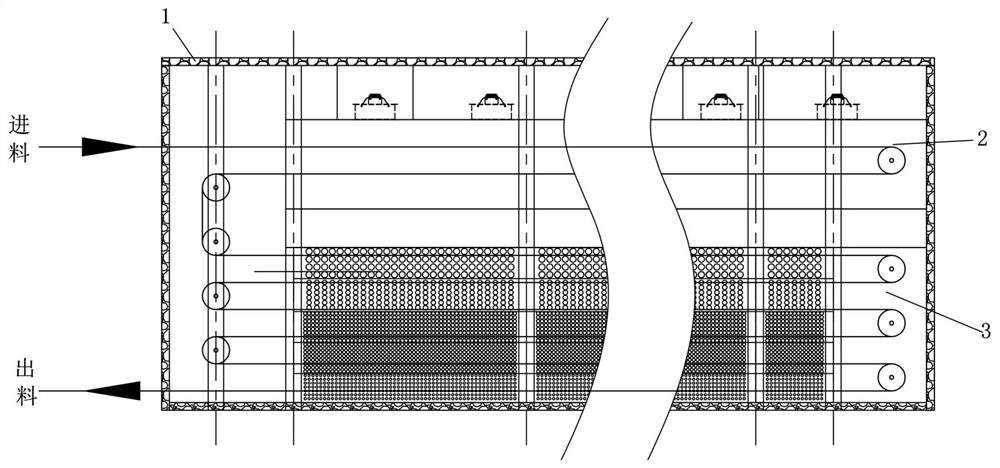

[0016] Embodiment of the present invention, see figure 1 As shown, a drying method for forming egg trays is provided, which is used for drying paper-plastic wet blanks. It is realized based on a double-layer structure of drying equipment 1. The upper layer of the drying equipment 1 is provided with a dehumidification chamber 2, and the lower layer is provided with a drying chamber. Dry chamber 3; the drying method includes the following contents: a dehumidification process and a drying process, wherein,

[0017] In the dehumidification process, in the dehumidification chamber 2, the paper-plastic wet billet is preheated and dehumidified in hot air. The dehumid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com