A modular splicing method of beam-column system

A modular, beam-column technology, applied in the direction of architecture, building construction, etc., can solve the problems of long construction time, waste of materials, long construction period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

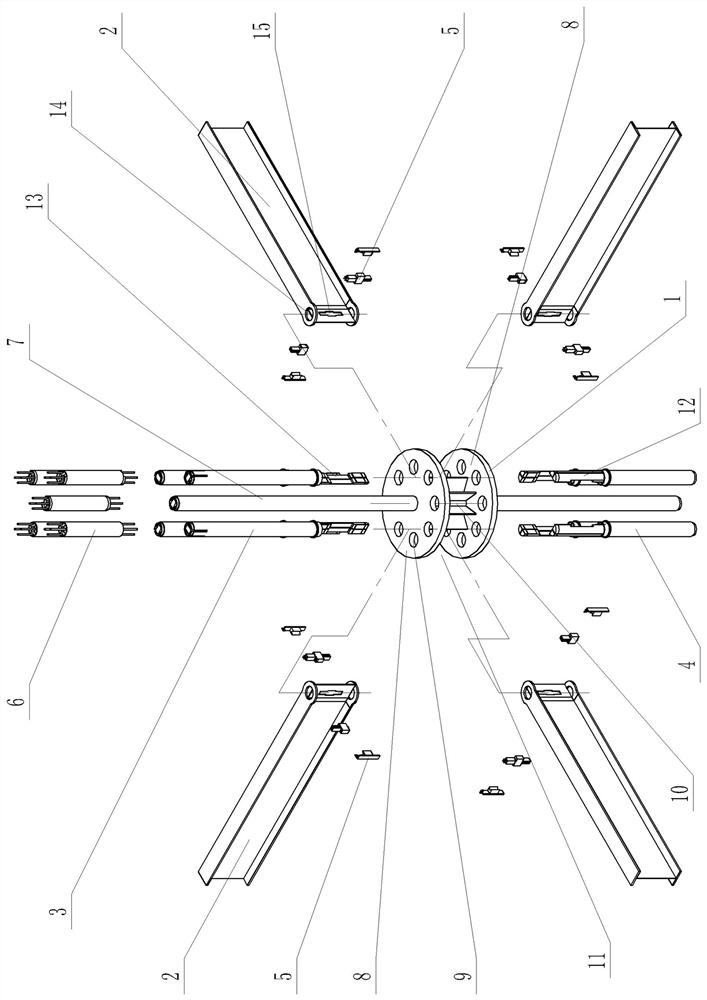

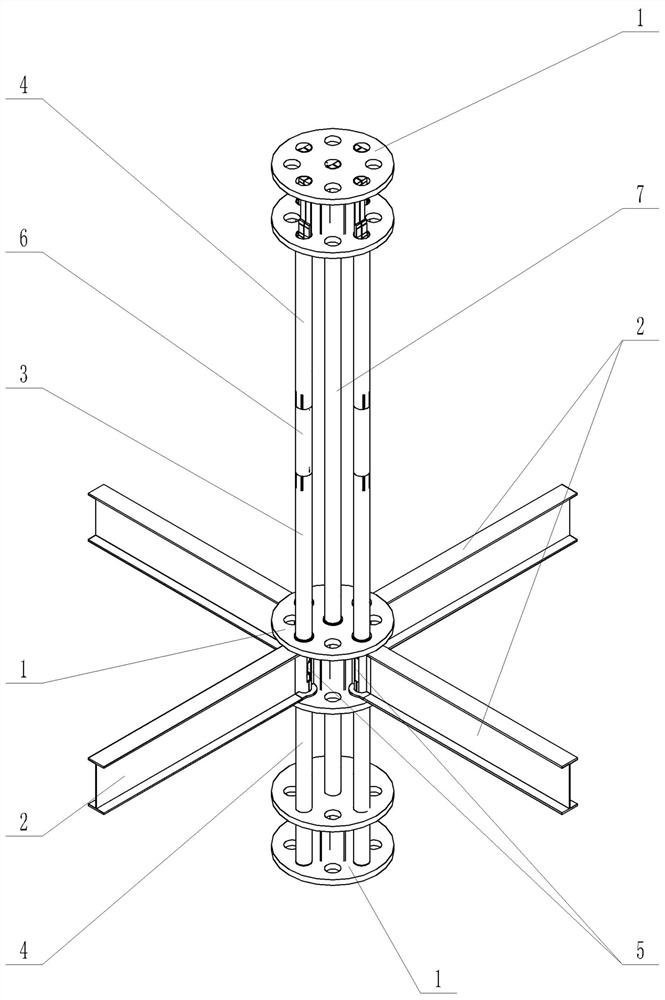

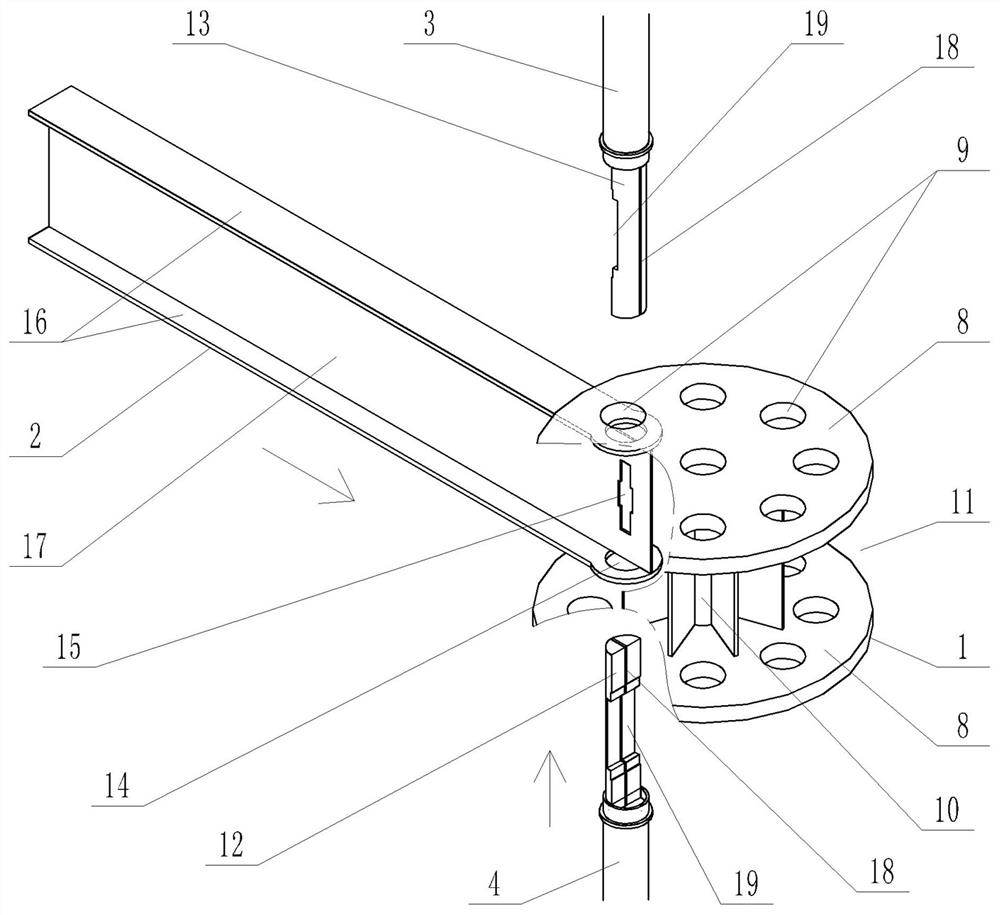

[0041] The specific steps of the present invention are described in detail. The beam-column system modular splicing method includes the following steps:

[0042] Step 1. First, according to the construction needs, fix the flange fastening plate 1 at the desired position; the flange fastening plate 1 is composed of two parallel-arranged circular beam column insertion plates 8, and the two horizontally arranged beam column The middle part of the socket 8 is connected by a vertical socket connection column 10 . Moreover, the middle part of the plug-in connection column 10 of the flange fastening disc 1 is provided with an intermediate column 7 through which the intermediate column 7 is used for basic positioning and is also a core stabilizing unit; The outer periphery of 7 is respectively provided with a number of beam column sockets 9 equidistantly arranged along the circumference; between the two beam column inserts 8 of the flange fastening plate 1, there is also a socket for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com