Pivot structure for opening and closing composite tent support

A technology of composite materials and tents, which is applied in the direction of tents/canopies, building types, buildings, etc., can solve the problems of not being able to meet the needs of tents, long installation time, small size of connectors and connecting rods, etc., to solve messy placement, improve Work efficiency, the effect of increasing practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

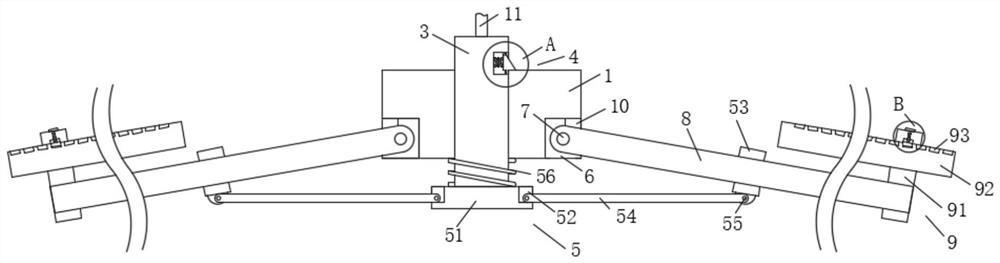

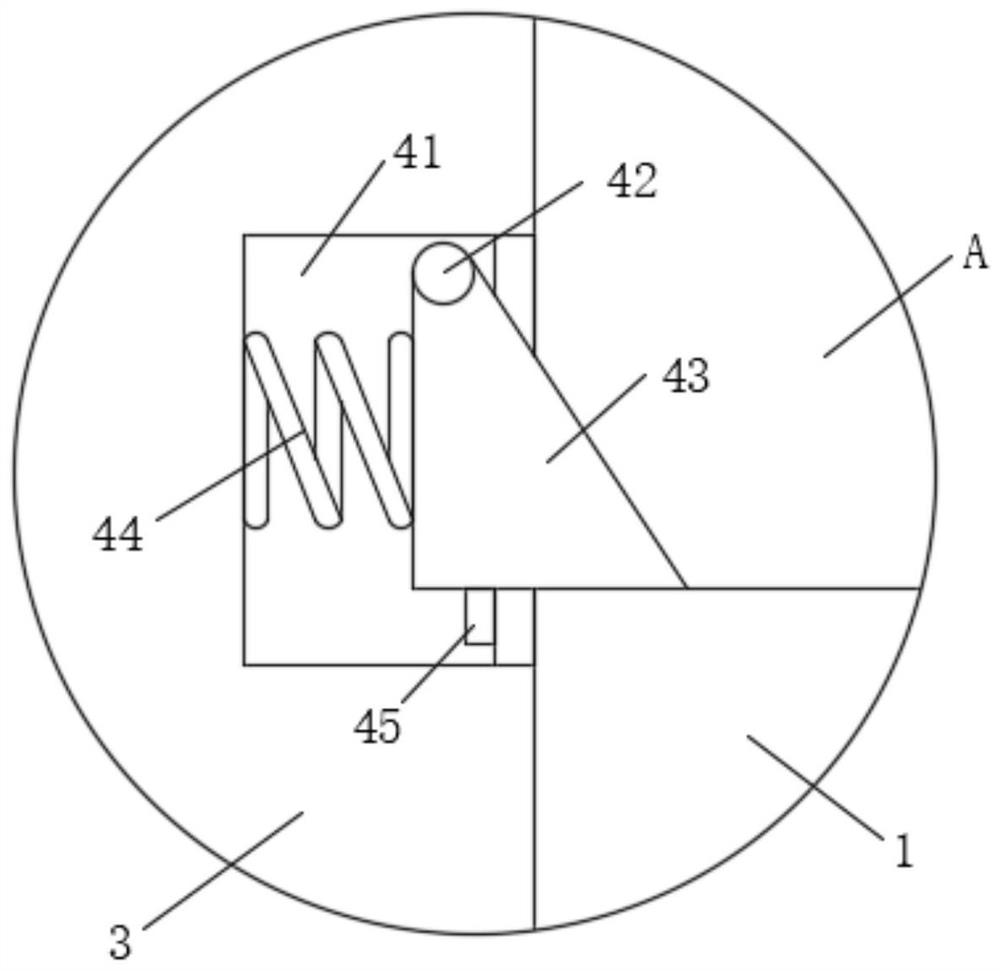

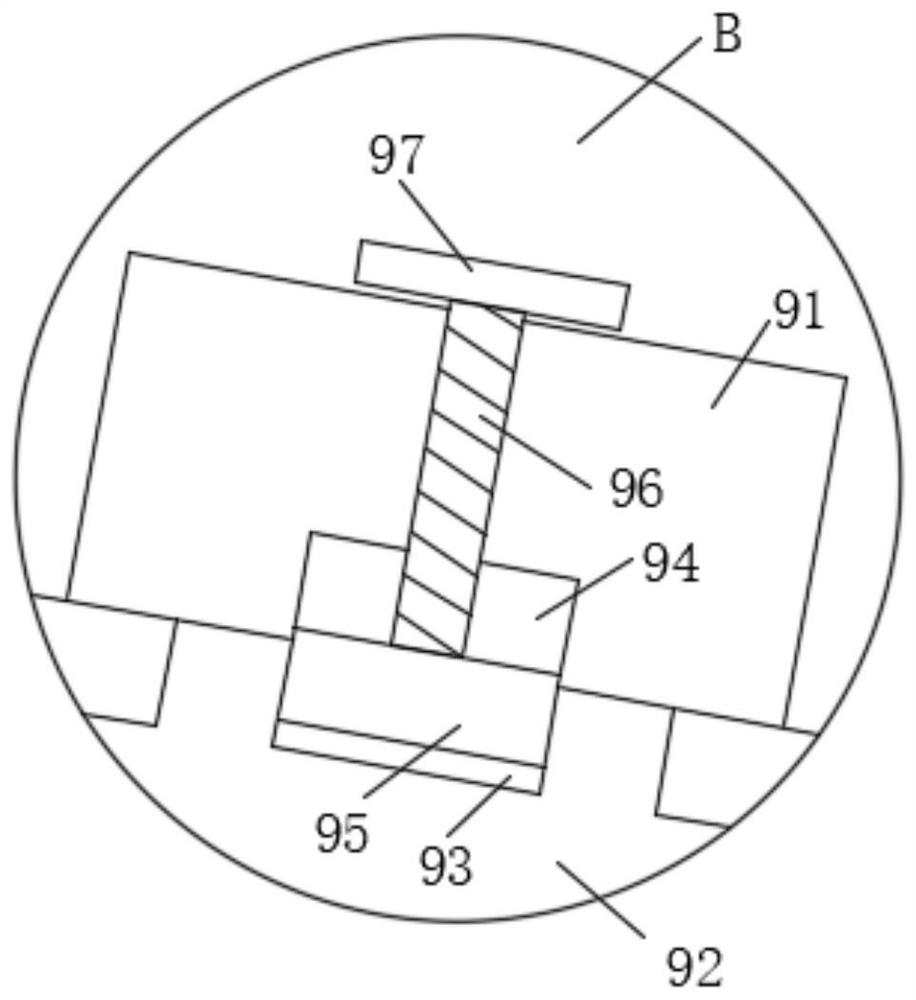

[0026] Example: such as Figure 1-5 As shown, the central structure for opening and closing a composite tent support of the present invention includes a support base 1, a fixed rod 3, a fixation mechanism 4, a support mechanism 5, a fixed bracket 8 and a telescopic mechanism 9, and the middle position of the support base 1 is provided with a A through hole 2, the fixed rod 3 is clamped in the through hole 2, the fixed mechanism 4 is fixedly connected in the fixed rod 3 and is located at the upper end of the support base 1, and four installations are evenly arranged on the outside of the lower end of the support base 1. Holes 6, four mounting holes 6 are fixedly connected with a first shaft 7, four fixed brackets 8 are provided, and the upper ends of the four fixed brackets 8 are respectively rotatably connected to the four first shafts 7 , the lower ends of the four fixed brackets 8 are fixedly connected with a telescoping mechanism 9, and the lower ends of the fixed rod 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com