Shockproof pump shaft assembly for magnetic drive pump and magnetic drive pump

A magnetic pump and pump shaft technology, which is applied to pump elements, components of a pumping device for elastic fluids, pumps, etc., can solve the problems of damaged shaft sleeves, poor dynamic balance, and difficult processing, and achieve concentricity. Good compensation, avoiding direct contact and high processing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

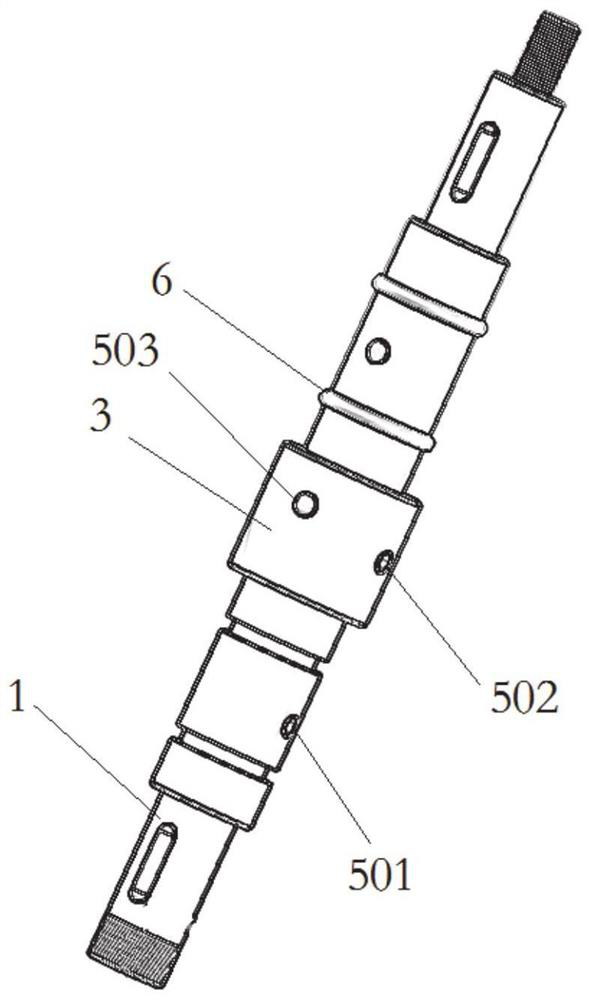

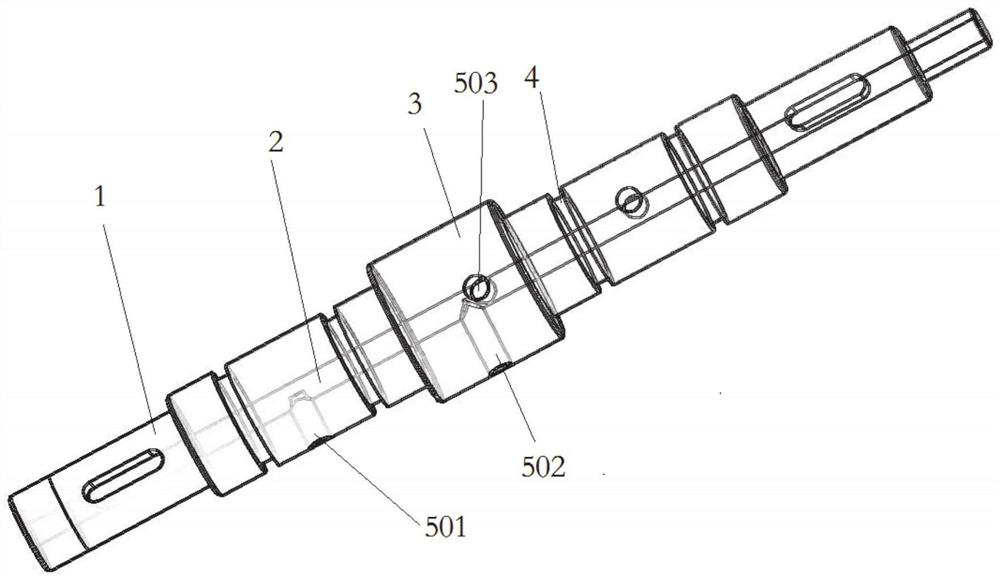

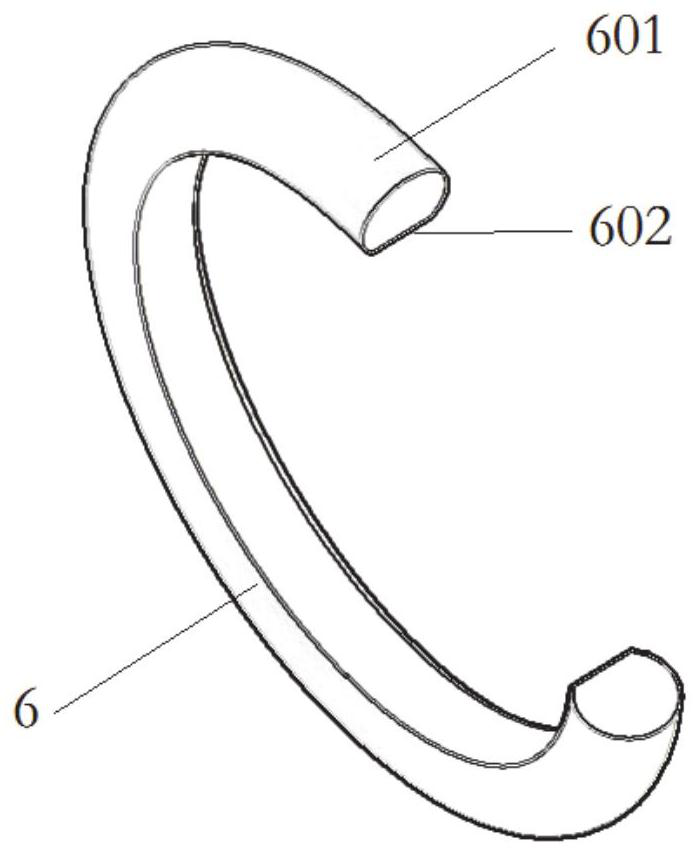

[0026] Such as Figure 1-Figure 3 As shown, a shock-proof pump shaft assembly for a magnetic pump is characterized in that it includes a pump shaft 1. A shaft sleeve is sleeved on the outer side of the pump shaft 1, and a rubber is provided between the shaft sleeve and the outer side of the pump shaft 1. Expanding ring 6, the outer side of the rubber expanding ring 6 is formed by a combination of an inner ring surface 601 and an outer arc surface 602, so that the cross-sectional profile of the rubber expanding ring 6 is D-shaped;

[0027] The outer circular side of the pump shaft 1 is provided with an annular groove 4, the inner ring surface 601 of the rubber expansion ring 6 fits the ring surface of the annular groove 4, and the outer arc surface 602 of the rubber expansion ring 6 protrudes from the annular groove 4 to The sleeve provides elastic support.

[0028] The pump shaft 1 is provided with a cooling flow channel 2 which penetrates the pump shaft 1 along the central axis o...

Embodiment 2

[0039] This embodiment provides a magnetic pump, which uses the shockproof pump shaft assembly for the magnetic pump described in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com