Pipe, pipe joint, combined pipe, sealing element and connecting method of combined pipe

A connection method and pipe joint technology, which is applied in the direction of pipes/pipe joints/fittings, pipe connection arrangements, pipes, etc., can solve problems such as pipe leakage, threats to the overall building quality of high-rise buildings, and poor connection stability, so as to avoid leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

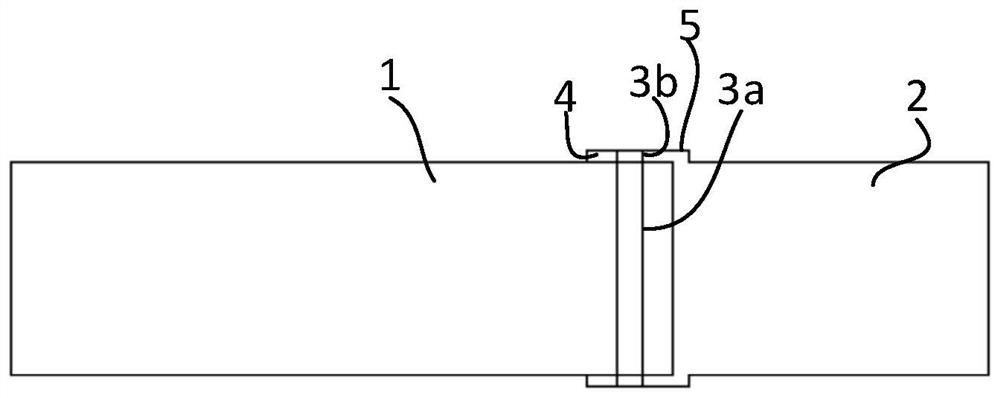

[0042] See attached figure 1 In the pipe provided by Embodiment 1 of the present invention, at the end of the pipe, at least one first groove or protrusion along the circumference of the pipe is provided along the inner or outer wall of the pipe. In this embodiment, the pipe 1 is provided with at least one (in this embodiment, two) grooves or protrusions 3a of the first type along the circumference of the pipe at least one (in this embodiment, two) grooves or protrusions 3a on the outer wall of the socket. The socket is provided with at least one (in this embodiment, two) first-type protrusions or grooves 3b on the inner wall, so that the grooves or protrusions 3a and the protrusions or grooves 3b form a one-to-one correspondence relation. Among them, in order to make the plugging between the pipe 1 and the pipe 2 more convenient, it is also possible to process a diameter-expanding convex ring at the socket 5 of the pipe 2 in the process of processing the pipe 2. At this time...

Embodiment 2

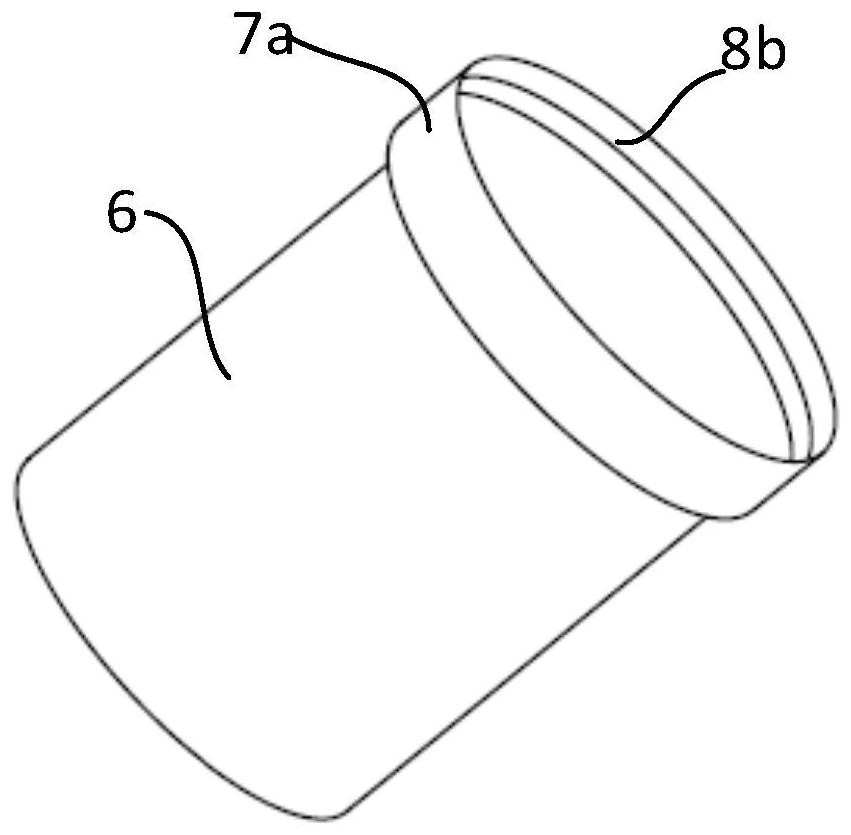

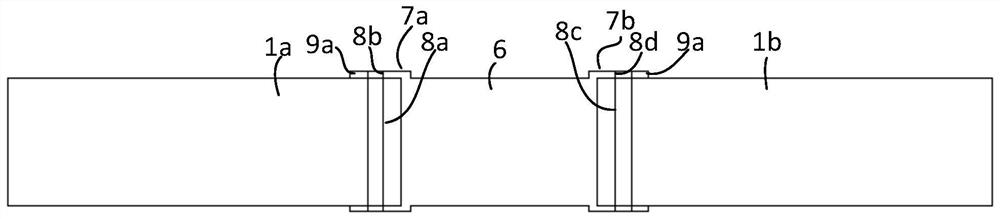

[0046] See attached figure 2 And attached image 3 The pipe joint provided by the second embodiment of the present invention is cylindrical, and the two axial ends of the pipe joint are respectively provided with a second type of groove or protrusion, and the shape of the second type of groove or protrusion is the same as that of the first type of concave Match the shape of the groove or protrusion. In this case, it is only necessary to make another pipe joint 6, so that the sockets 7a, 7b at both ends of the pipe joint 6 are respectively inserted into the pipe materials 1a, 1b to be inserted, and then the pipe materials 1a, 1b to be inserted can be realized. The connection between 1b is convenient for insertion and connection, and the manufacturing cost is low. Wherein the overall outer diameter of the pipe joint 6 may be uniform, or for the convenience of treating the connection between the inserted pipes 1a, 1b, a diameter-expanding protruding ring 7a and 7b may be proce...

Embodiment 3

[0048] See attached figure 1 The first composite pipe material provided by Embodiment 3 of the present invention includes multiple sections of the pipe material provided by the present invention, and each section of pipe material is connected in series through the first type of groove or protrusion. In this embodiment, the pipe 1 is provided with at least one (in this embodiment, two) grooves or protrusions 3a of the first type along the circumference of the pipe at least one (in this embodiment, two) grooves or protrusions 3a on the outer wall of the socket. The socket is provided with at least one (in this embodiment, two) first-type protrusions or grooves 3b on the inner wall, so that the grooves or protrusions 3a and the protrusions or grooves 3b form a one-to-one correspondence relation. Among them, in order to make the plugging between the pipe 1 and the pipe 2 more convenient, it is also possible to process a diameter-expanding convex ring at the socket 5 of the pipe 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com