Hardness plug temperature measuring method

A hardness plug, hardness technology, applied in the field of hardness plug temperature measurement, can solve the problem of not reflecting the temperature change of the object to be measured, and achieve the effect of accurate reflection, true and accurate results, and avoidance of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

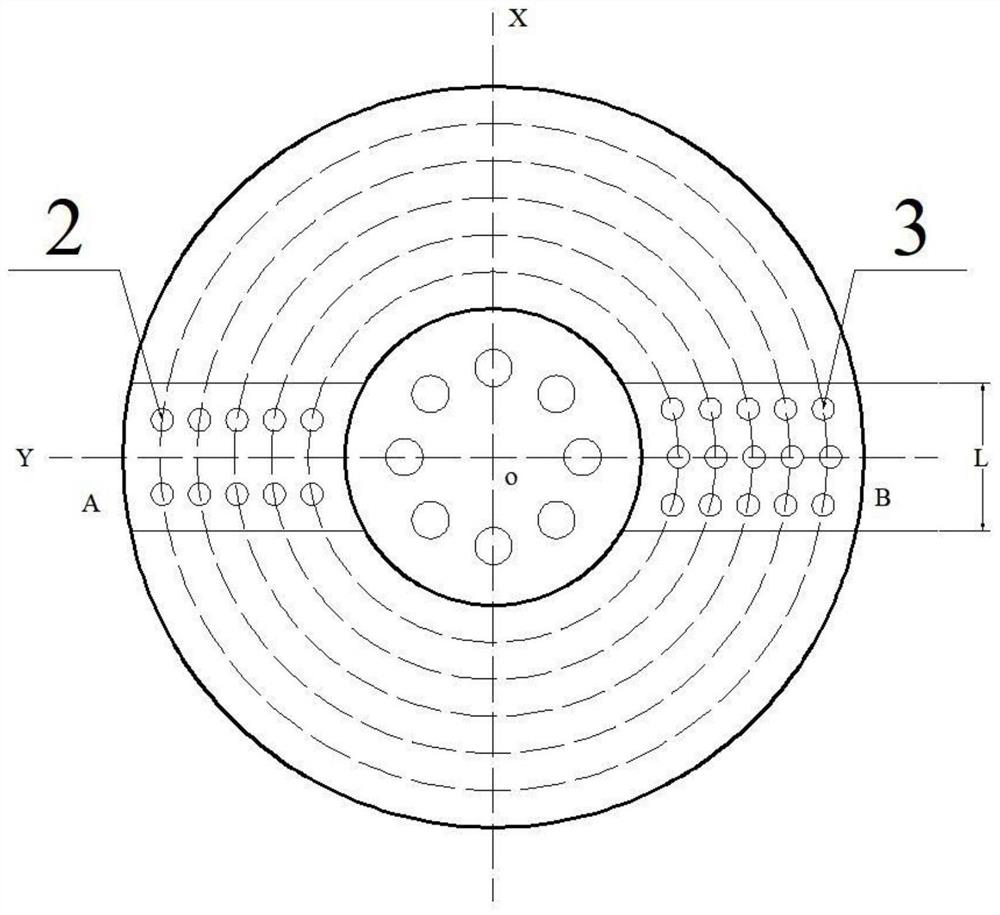

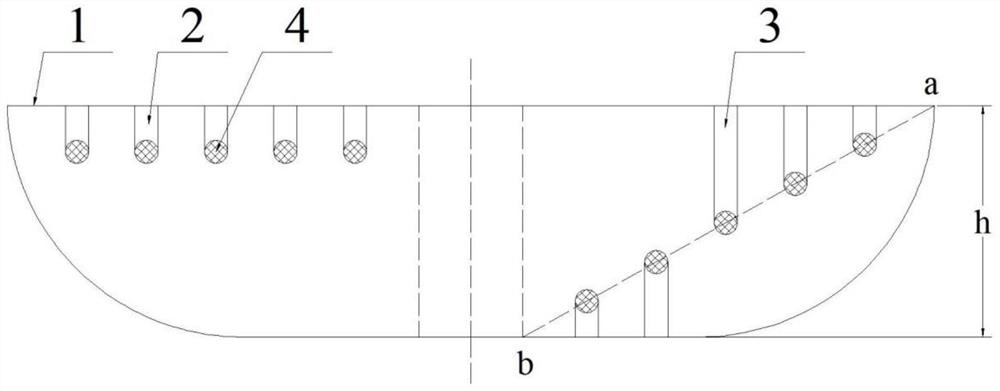

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] In this embodiment, an engine flywheel of a heavy truck is used as the object 1 to be tested, and a hardness plug 4 is drilled on the working surface of the object 1 to be tested. The method for making the hardness plug 4 of the present embodiment is as follows:

[0035] First, select GCr15 steel as the material for preparing the hardness plug 4, process it into a hardness plug 4 of M3×0.5×4, and use it for later use after complete quenching. fire, measure the hardness of the hardness plug 4, and make a corresponding relationship diagram between the hardness of the hardness plug 4 and the tempering temperature, and the fitting can obtain the tempering temperature-hardness linear equation of the hardness plug 4 used as:

[0036] T=-1.0585X+943.01

[0037] Among them, T is the tempering temperature of hardness plug 4, the unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com