Fly trap for food processing

A technology of food processing and fly killers, which is applied to the application, devices for catching or killing insects, animal husbandry, etc. It can solve the problems of poor fly killing efficiency, inability to catch flies, unfavorable large-scale use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

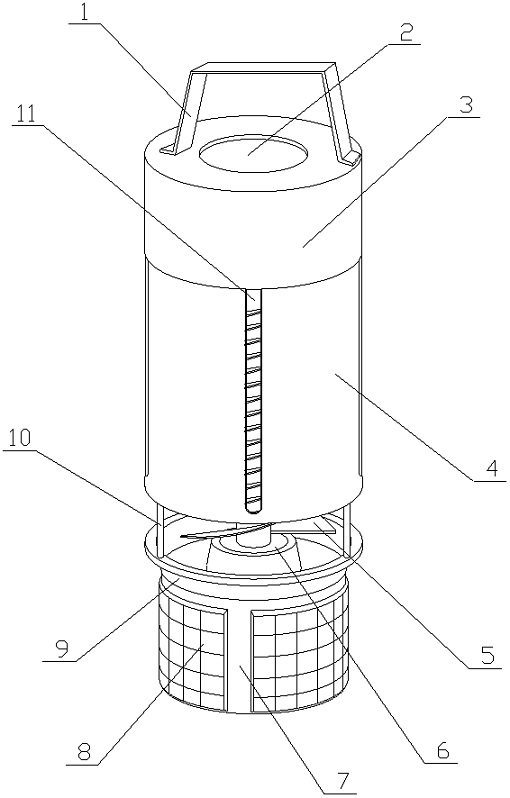

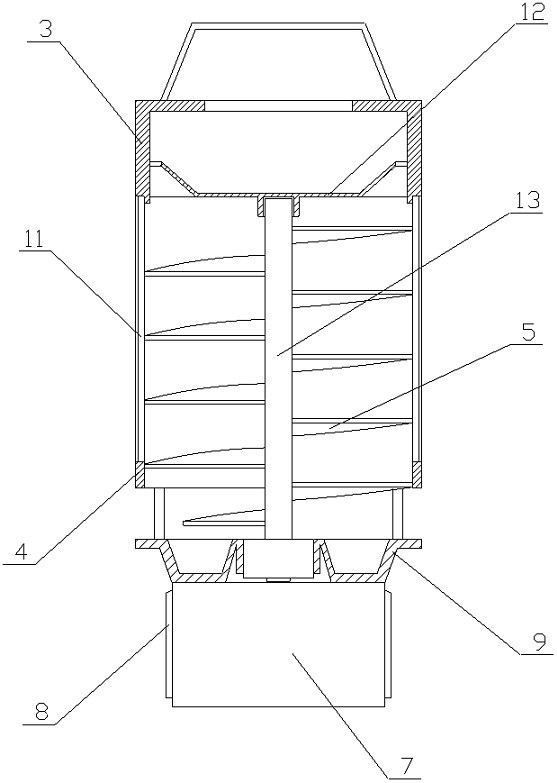

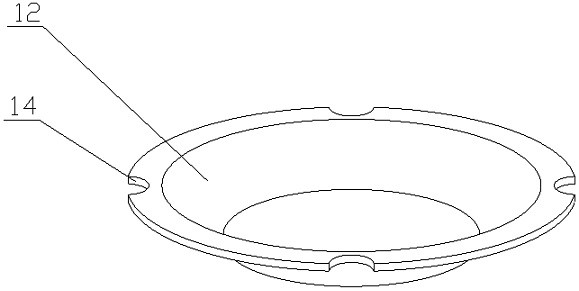

[0016] A fly killer for food processing of the present invention is achieved in the following way: a fly killer for food processing of the present invention consists of a fixed frame (1), a built-in lamp (2), an upper box (3), a lower box (4 ), spiral blade (5), drive motor (6), battery (7), photovoltaic panel (8), bait plate (9), fixed rod (10), light-transmitting film (11), inner partition (12) , a drive rod (13) and a catch hole (14), the bait tray (9) is placed on the top of the battery (7), and a plurality of photovoltaic panels (8) are placed on the outer wall of the battery (7). An annular groove is clamped on the bait pan (9), the edge of the bait pan (9) extends to a supporting platform, one end of a plurality of fixed rods (10) is placed on the edge of the bait pan (9) at an equal angle, and the lower box (4 ) placed on the other end of the fixing rod (10), the lower box (4) is distributed with a plurality of through grooves along the circumferential direction, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com