Rotational flow electronic cigarette atomizer structure and rotational flow electronic cigarette atomizer thereof

An electronic cigarette vaporizer and swirl technology, applied in the field of electronic cigarettes, can solve the problems of waste, insufficient atomization, discomfort, etc., and achieve the effects of saving e-liquid, preventing e-liquid leakage, and reducing discomfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

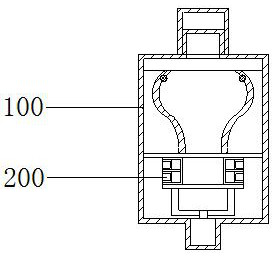

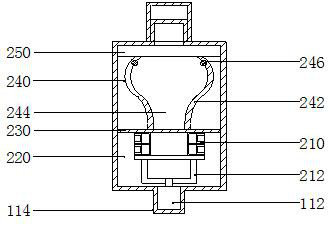

[0037] see Figure 1-5 , the present invention provides a technical solution: the structure of the swirl electronic smoke atomizer and the swirl electronic smoke atomizer include a shell assembly 100 and an internal assembly 200 .

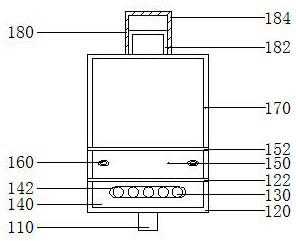

[0038] see figure 1 , figure 2 , Figure 4 as well as Figure 5 The shell assembly 100 includes a connecting piece 110, a base 120, a first cylinder 150, a second cylinder 170 and a mouthpiece 180, the connecting piece 110 is connected to the bottom of the base 120, and the base 120 is provided with a first air inlet 130 , the first cylinder 150 is connected above the base 120 , the first cylinder 150 is provided with a second air inlet 160 , the second air inlet 160 is inclined, and the second cylinder 170 is connected to the first cylinder 150 Above, the mouthpiece 180 is connected to the upper end of the second barrel 170 . A first sealing ring 122 is disposed between the base 120 and the first cylinder 150 , and a second sealing ring 152 ...

Embodiment 2

[0041] see Figure 1-5 , the present invention provides a technical solution: the structure of the swirl electronic smoke atomizer and the swirl electronic smoke atomizer include a shell assembly 100 and an internal assembly 200 .

[0042] see figure 1 , figure 2 , Figure 4 as well as Figure 5 , the housing assembly 100 includes a connector 110, a base 120, a first cylinder 150, a second cylinder 170 and a mouthpiece 180, the connector 110 is connected to the bottom of the base 120, and the connector 110 includes an electrode bolt 112 and an insulating sleeve 114 , the electrode bolt 112 is connected to the bottom of the base 120 , and the insulating sleeve 114 is sleeved on the outside of the electrode bolt 112 . The electrode bolt 112 is electrically connected to the electronic cigarette battery, and the insulating sleeve 114 protects the electrode bolt 112 . The base 120 is provided with a first air inlet 130 , and the outside of the base 120 is slidably sleeved wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com