Compression treatment device for metal waste

A technology of garbage compression and treatment device, applied in the direction of press, magnetic separation, solid separation, etc., can solve the problems of hidden safety hazards, high metal garbage, inability to screen recycling value, etc., to achieve the effect of convenient cleaning and convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

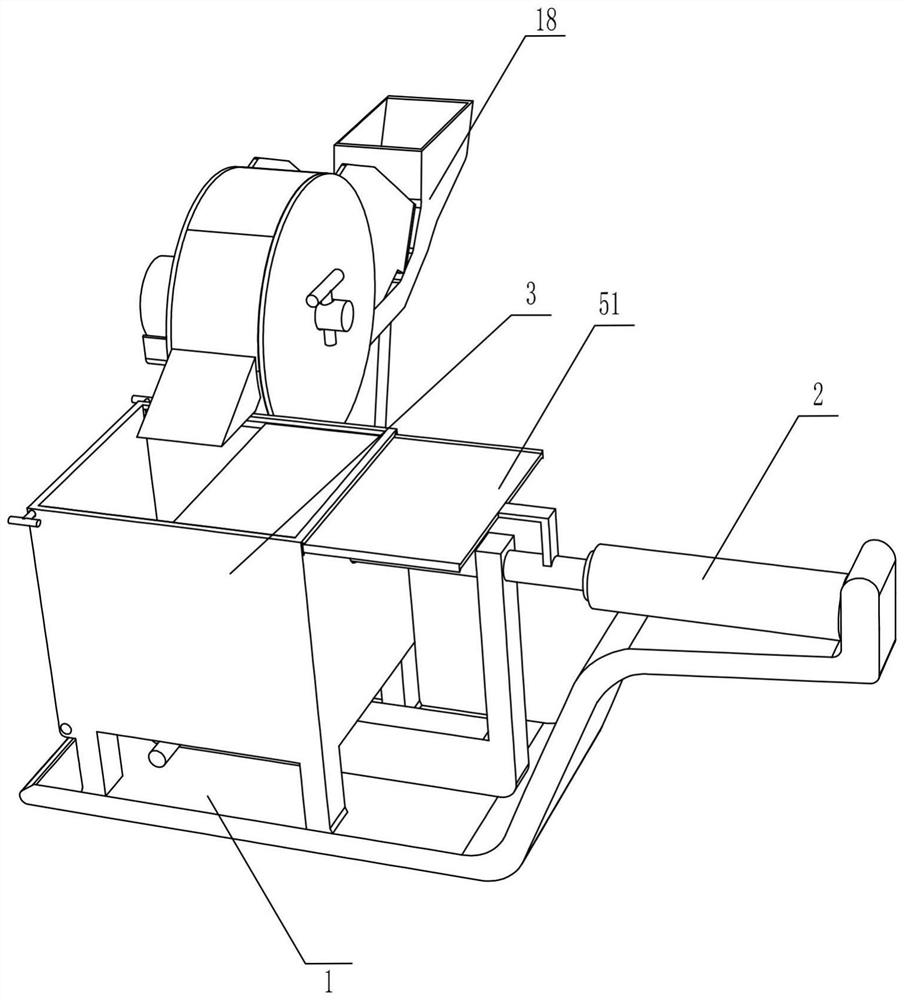

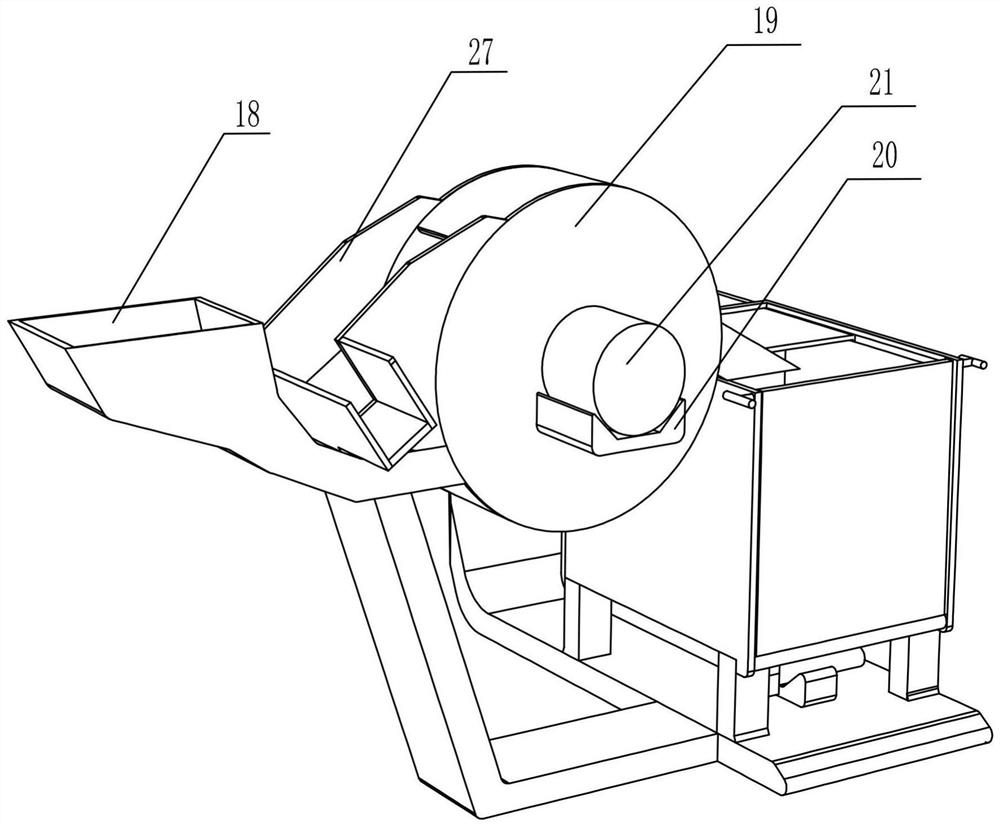

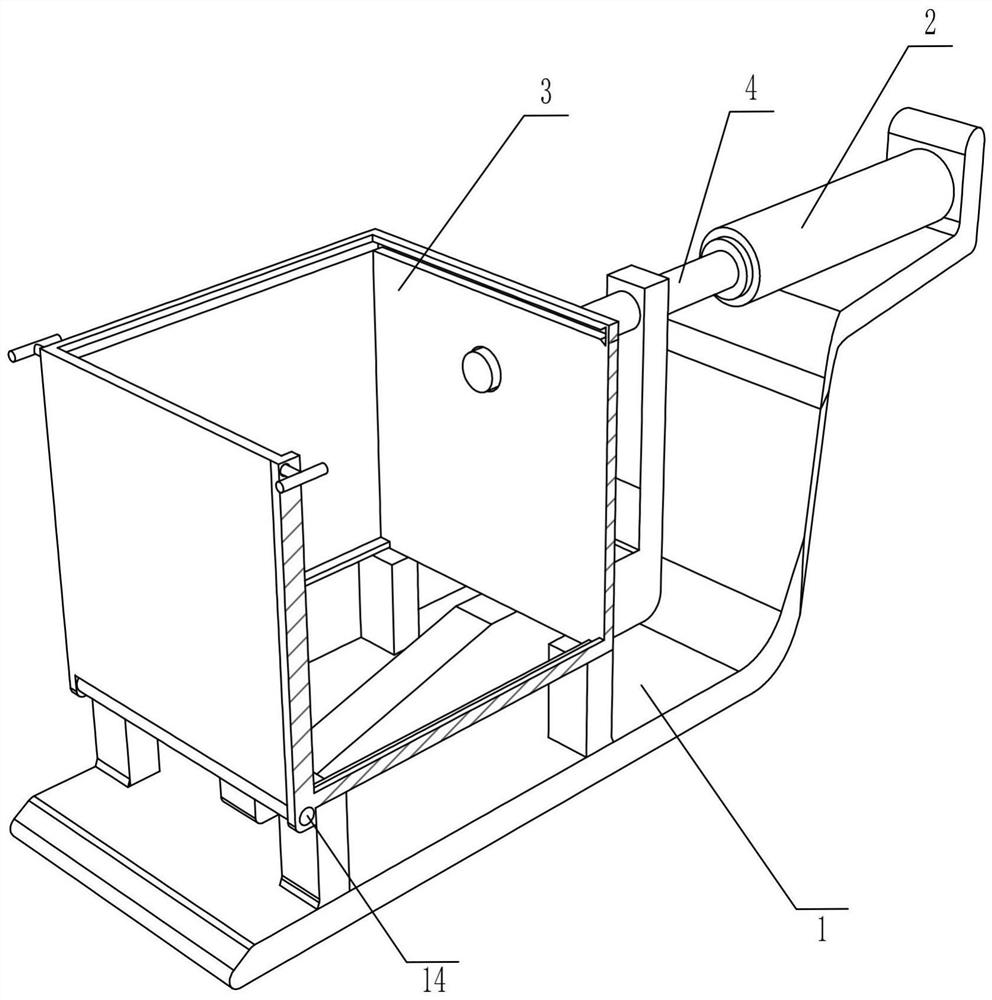

[0025] Such as Figure 1-Figure 8 As shown, a metal garbage compression treatment device includes a base 1, an electric push rod 2, an extrusion box 3, a push rod 4, a connecting frame 5, a sealing plate 51, an extrusion plate 6, a compression mechanism and a discharge mechanism , the electric push rod 2 that plays a driving role is fixedly installed on the base 1, and the extruded box 3 that is provided with two round holes and used as non-magnetic metal waste is fixedly installed on the base 1, and the push rod 4 It is fixedly installed on the left end of the electric push rod 2 and is slidably connected with the extrusion box body 3. The connecting frame 5 that plays a connecting role is fixedly installed on the push rod 4, and the sealing plate 51 that plays a sealing role is slidably installed on the extrusion box body 3. Pressed on the box body 3 and fixedly connected with the left end of the connecting frame 5, the extrusion plate 6 which acts as extrusion is fixedly in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com