Railway vehicle parking brake device capable of automatically stopping and manually stopping

A technology for parking braking and railway vehicles, which is applied to the operating mechanism of railway vehicle brakes, railway braking systems, pneumatic brakes, etc., and can solve the problems of occupying more human resources, complex structure and inconvenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments.

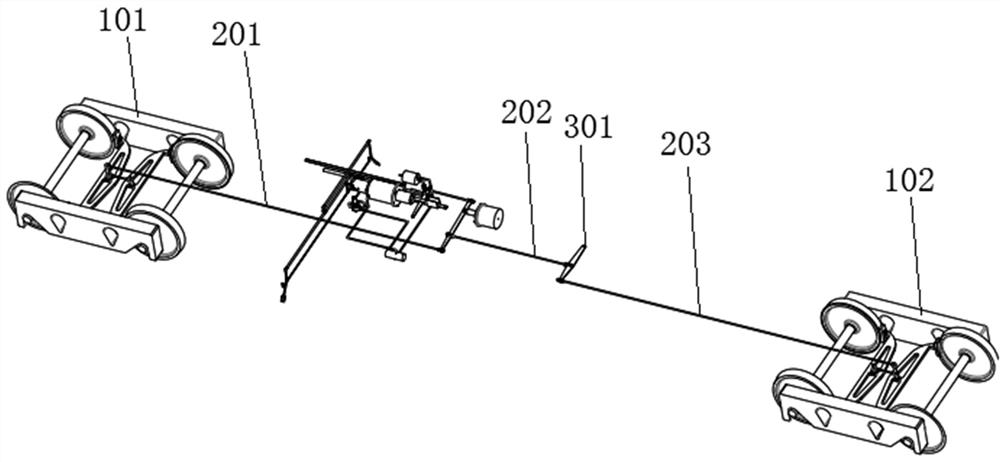

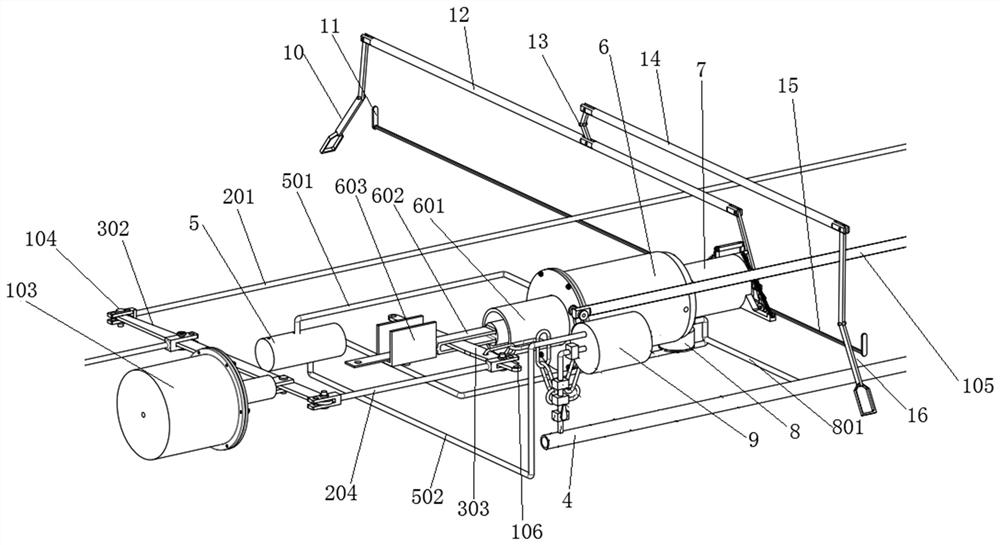

[0091] The utility model relates to a railway vehicle parking brake device capable of both automatic stop and manual stop, comprising a wind pressure mechanism, a hydraulic mechanism, a control mechanism and an executive mechanism.

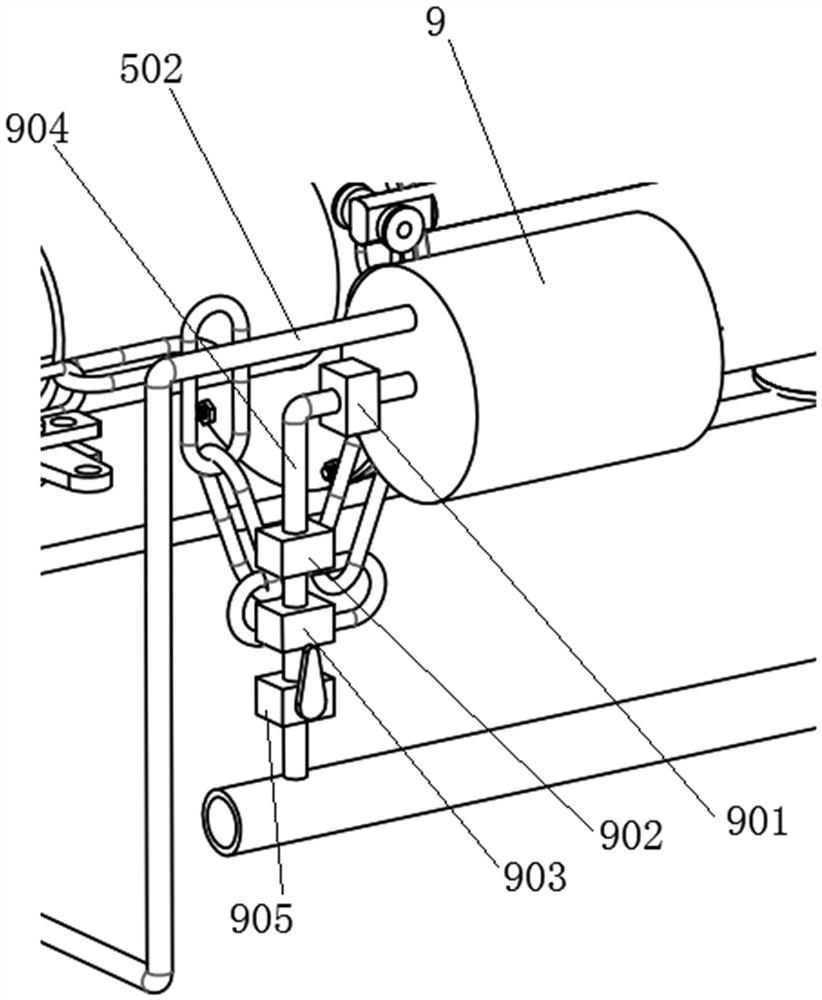

[0092] The air pressure mechanism includes a parking brake cylinder 6 , a parking air cylinder 9 , a local decompression valve 8 and a blocking valve 5 connected by air pipes.

[0093] Parking brake cylinder 6 The cylinder body is in the shape of a cylindrical barrel. The front end of the cylinder body is equipped with a parking brake cylinder front cover 606 with a first through hole in the center, and a second through hole is opened in the center of the rear end of the cylinder body; The first piston 608, the rear end of the first piston 60...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap