Efficient heat dissipation LED lamp bead based on heat dissipation area

A technology of LED lamp beads and heat dissipation area, which is applied in the direction of lighting and heating equipment, components of lighting devices, cleaning methods using tools, etc., which can solve high maintenance costs, reduce maintenance costs, large personnel and resource investment, etc. problem, achieve the effect of reducing energy consumption and use cost, improving stability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

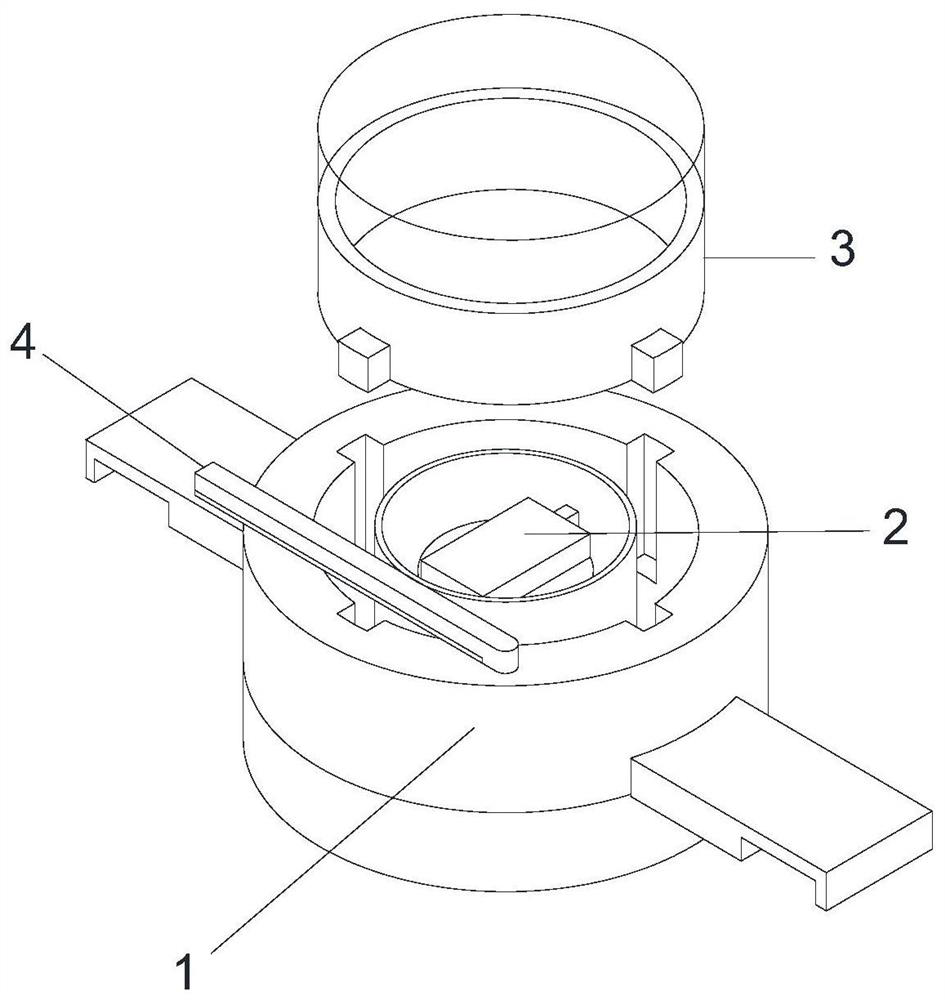

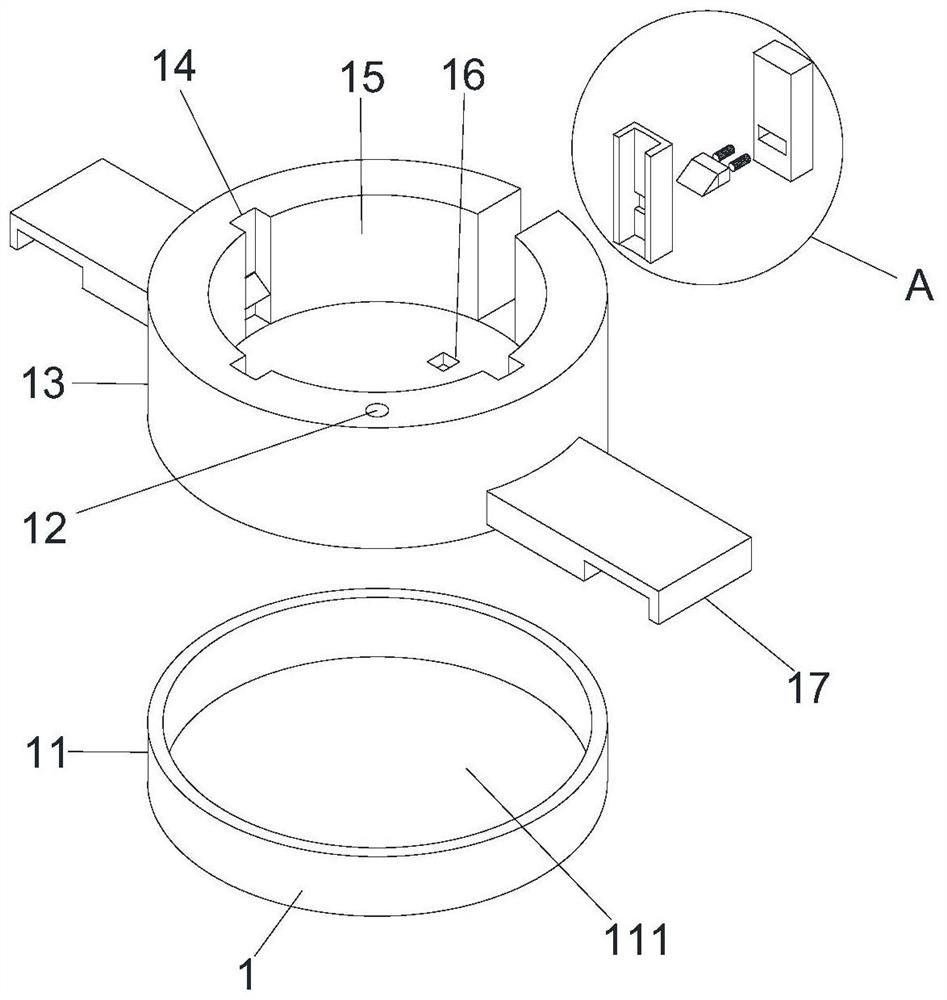

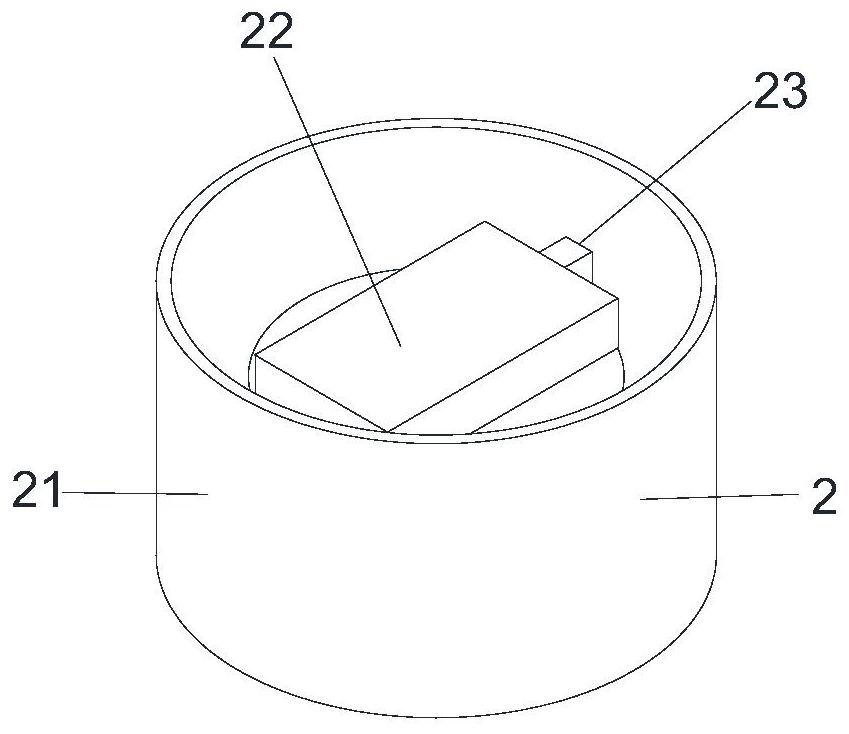

[0025] Embodiment: a kind of high-efficiency heat dissipation LED lamp bead based on heat dissipation area, such as Figure 1-Figure 6 Shown, comprise support 1, support 1 comprises frame body 13, two fixed mounts 17 and four slide grooves 14, the lower surface of frame body 11 is provided with chassis 11, and the upper surface of chassis 11 is fixed with the lower surface of frame body 13 Connection, the middle part of the upper surface of the chassis 11 is provided with a circular groove one 111, and a sweeping device 4 is arranged in the circular groove one 111, and the sweeping device 4 includes a sweeping rod 45, a rotating rod 43 and a liquid storage cylinder 41, and the liquid storage cylinder The front end of 41 is provided with telescopic rod 48, the lower surface of heat conducting rod one 23 is provided with heat conducting rod two 47, the lower surface of heat conducting rod one 23 is fixedly connected with the left end of the upper surface of heat conducting rod tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com