Vacuum reaction system for grain boundary diffusion technology

A technology of reaction system and grain boundary diffusion, applied in lighting and heating equipment, furnace components, furnace types, etc., can solve the problems of slow cooling speed of sintering equipment and inability to achieve rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The application will be described in further detail below in conjunction with the accompanying drawings.

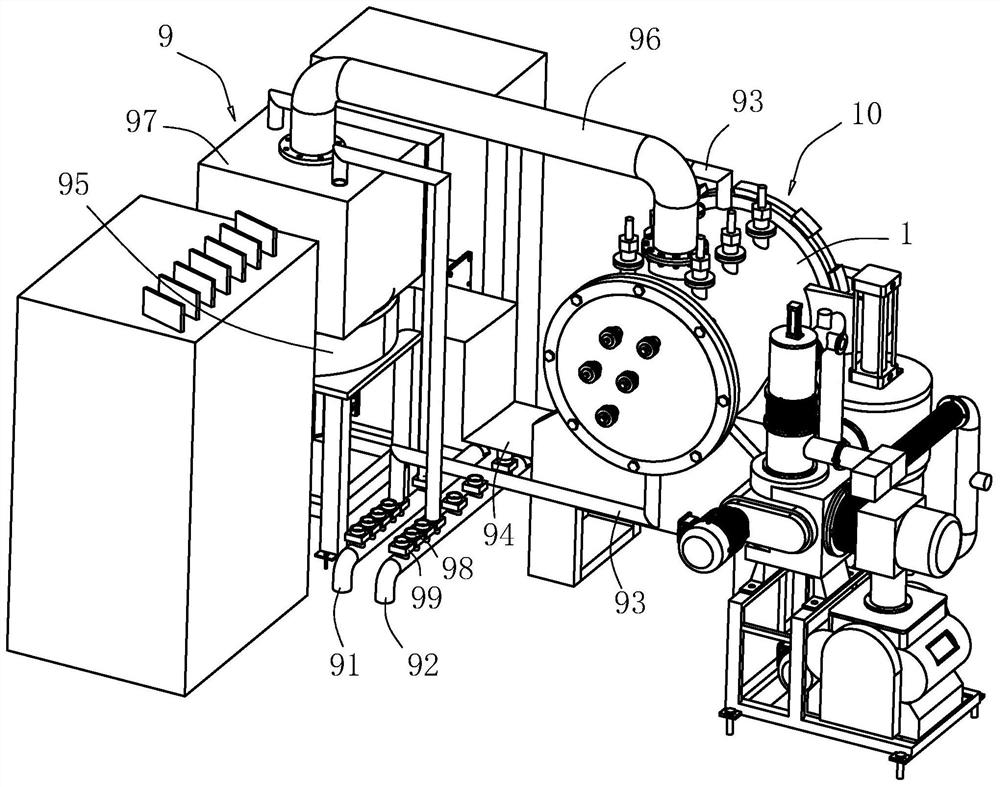

[0036] refer tofigure 1 , the present application provides a vacuum reaction system for grain boundary diffusion process, including a vacuum furnace 10 capable of heating internal workpieces and a rapid cooling device 9 arranged outside the vacuum furnace 10 and capable of cooling the vacuum furnace 10 .

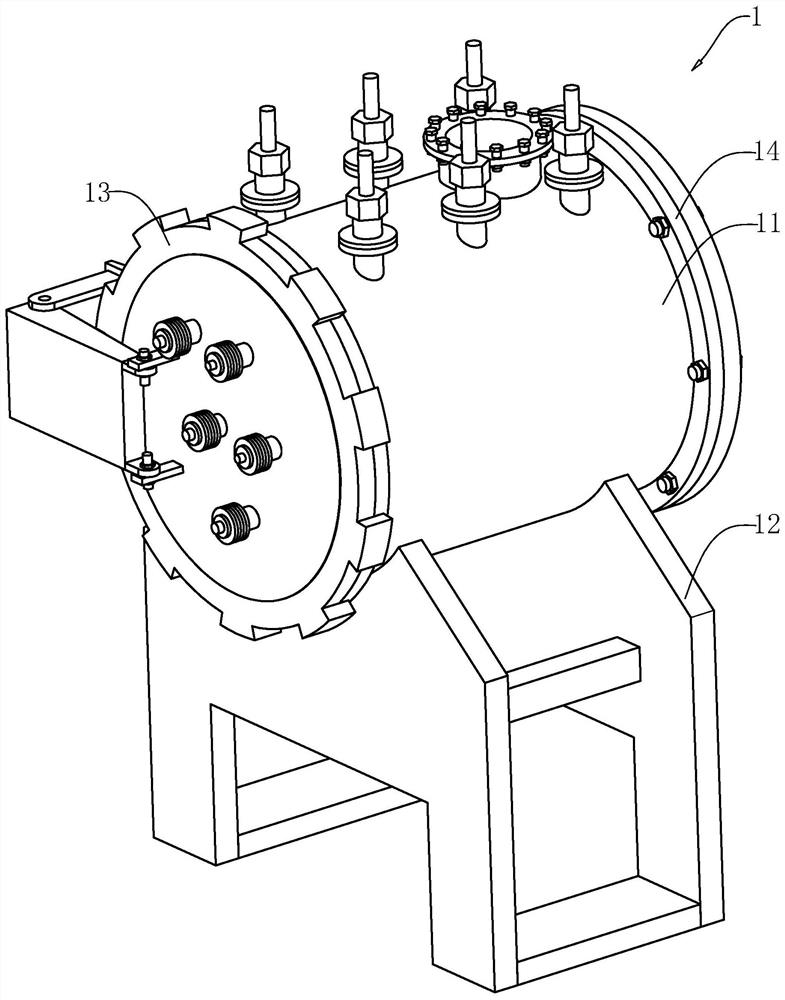

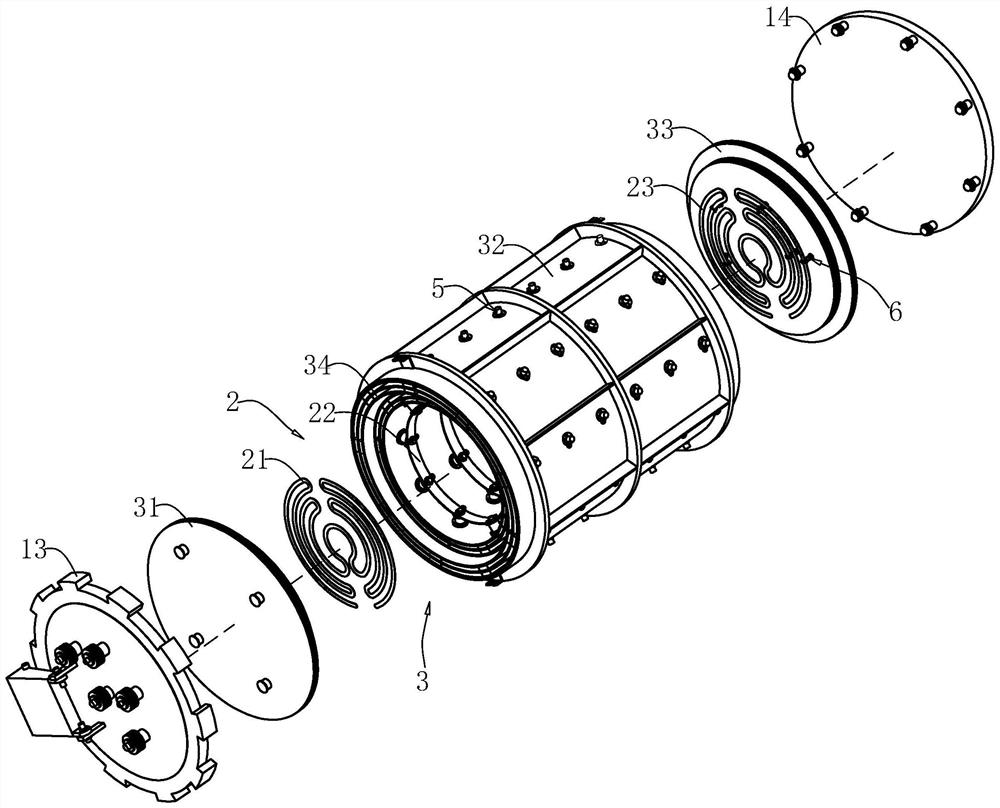

[0037] refer to figure 2 with image 3 , the vacuum furnace 10 includes a furnace body 1, a heater 2 arranged in the furnace body 1, and a reflective screen 3 between the furnace body 1 and the heater 2; the furnace body 1 is mainly used to place workpieces to be processed; the heater 2 is mainly used to heat the workpiece at high temperature; the reflective screen 3 is mainly used to keep the furnace body 1 warm and insulated.

[0038] refer to figure 2 , the furnace body 1 includes a furnace shell 11 with a hollow interior and open ends at both ends. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com