Bending resistance detection device for elevator guide rail production

An elevator guide rail and detection device technology, which is applied to measurement devices, uses a stable bending force to test the strength of materials, and tests of mechanical parts, etc., can solve the problems of simple structure of the detection device, low detection efficiency, influence of detection results, etc., To achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

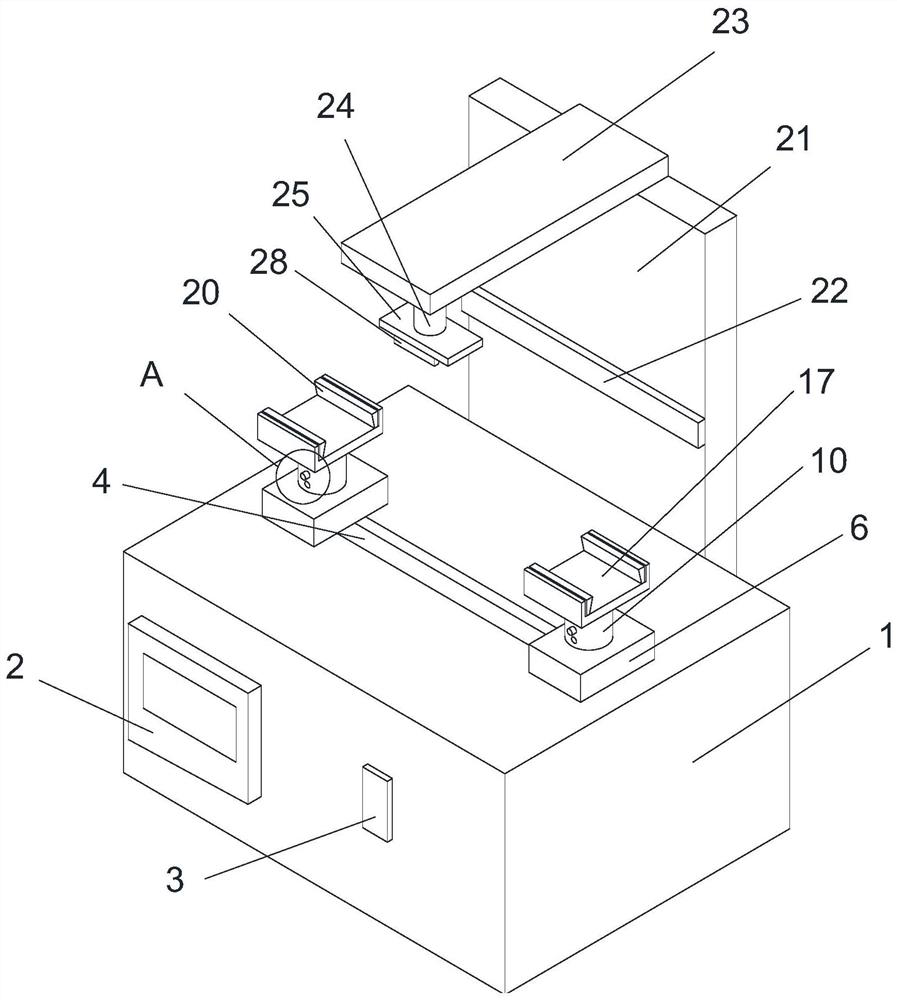

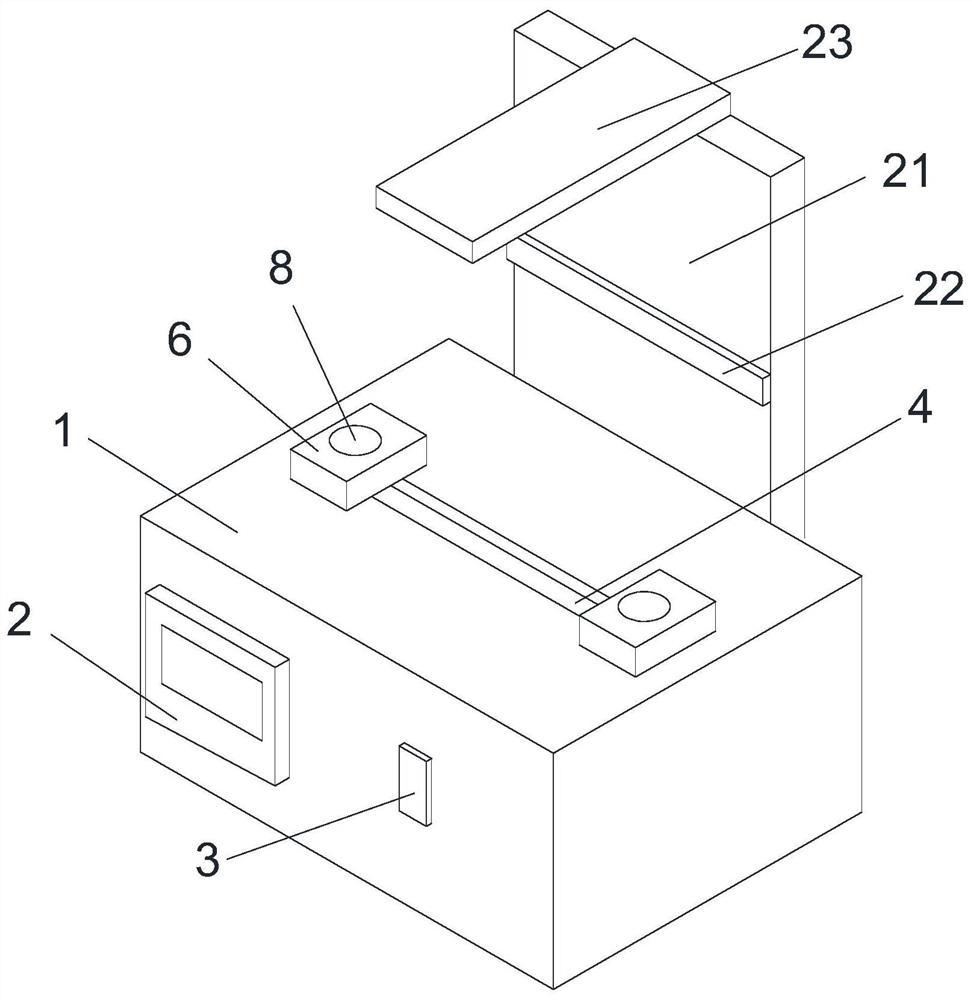

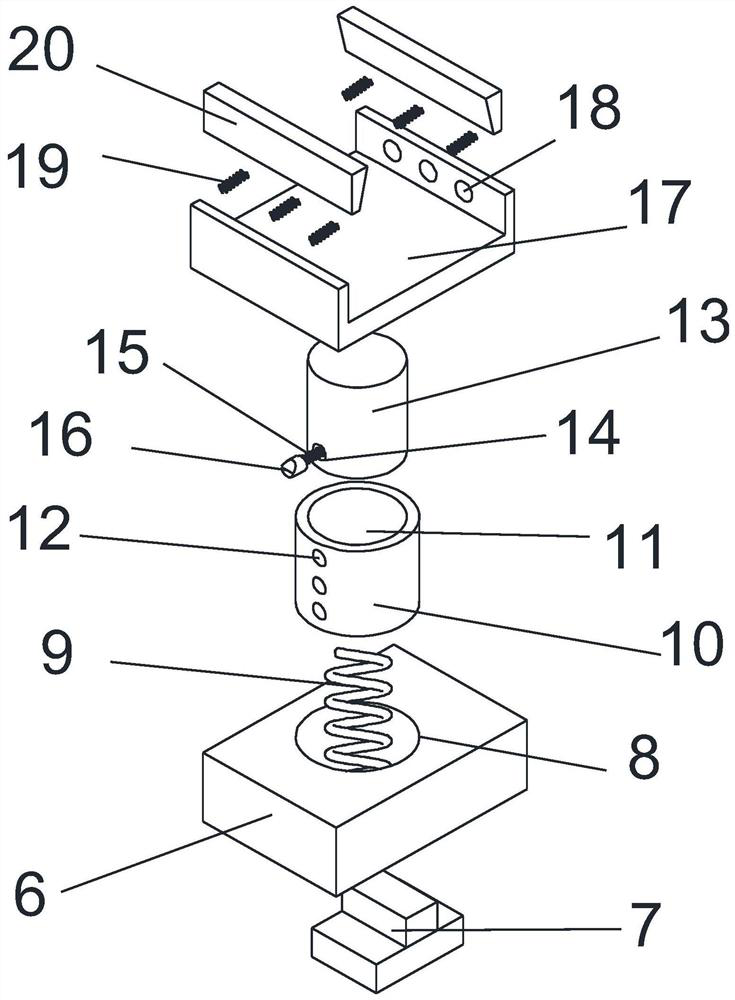

[0025] Embodiment: a kind of bending resistance detection device for elevator guide rail production, such as Figure 1-Figure 6 As shown, including a main body 1, the main body 1 is a rectangular block, the rear end of the right wall of the main body 1 is fixedly installed with a display 2, and the display 2 is a prior art, which will not be discussed here, and the right side wall of the display 2 is fixedly installed with a display screen The front end of the right wall of the main body 1 is fixedly equipped with a switch 3, the switch 3 is located in front of the display 2, the upper wall of the main body 1 is provided with an adjustment groove 4, the adjustment groove 4 is a "T" shaped groove in cross section, and the adjustment groove 4 The telescopic rods 5 are fixedly installed at the corresponding points on the front and rear walls of the interior, and the two groups of telescopic rods 5 are distributed in mirror images. There are two groups of adjustment blocks 6 above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com