Optical system, camera module and electronic equipment

A technology of optical system and camera module, applied in optics, optical components, instruments, etc., can solve problems such as driving risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

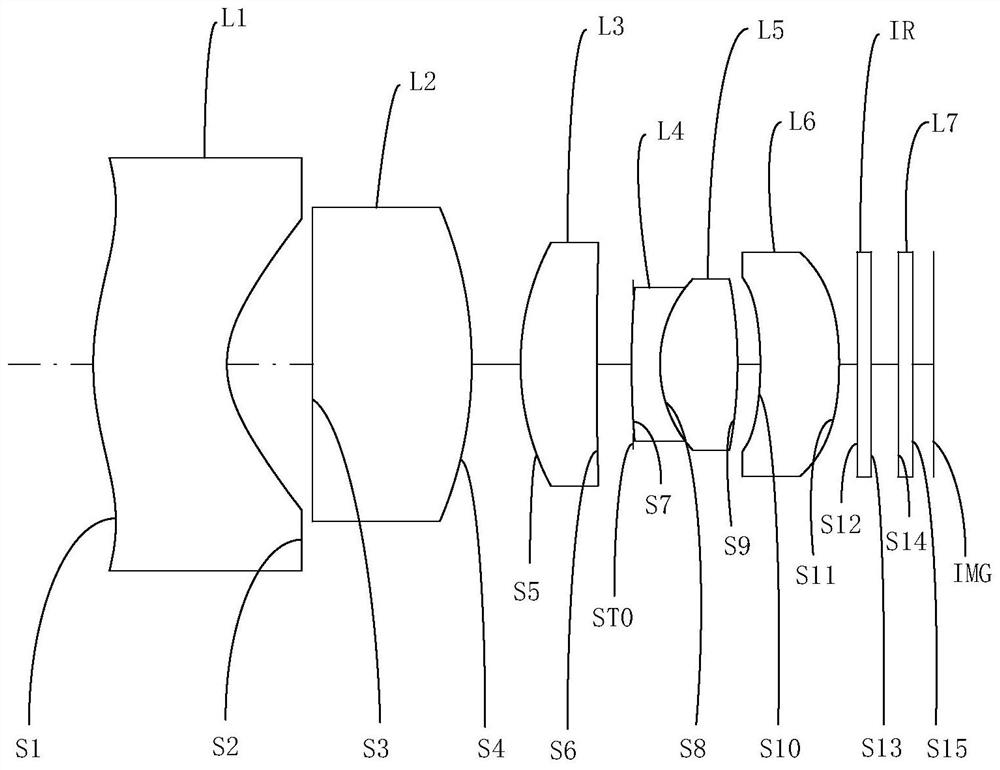

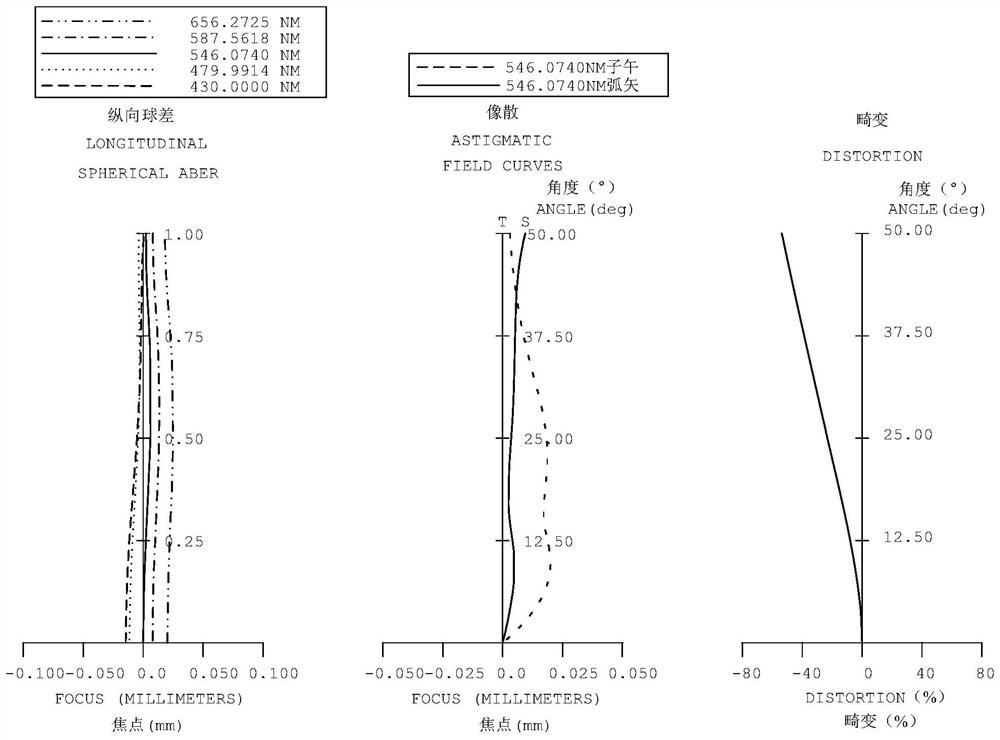

[0053] Please refer to Figure 1a and Figure 1b , the optical system of this embodiment includes in sequence from the object side to the image side along the optical axis direction:

[0054] The first lens L1 has a negative refracting force. The object side S1 of the first lens L1 is convex at the near optical axis and concave at the circumference; the image side S2 of the first lens L1 is concave at the near optical axis and concave at the circumference. place is flat;

[0055] The second lens L2 has a positive refractive power, the object side S3 of the second lens L2 is a plane, and the image side S4 is a convex surface;

[0056] The third lens L3 has a positive refractive power, the object side S5 of the third lens L3 is a convex surface, and the image side S6 is a concave surface;

[0057] The fourth lens L4 has negative refractive power, the object side S7 of the fourth lens L4 is convex, and the image side S8 is concave;

[0058] The fifth lens L5 has a positive ref...

no. 2 example

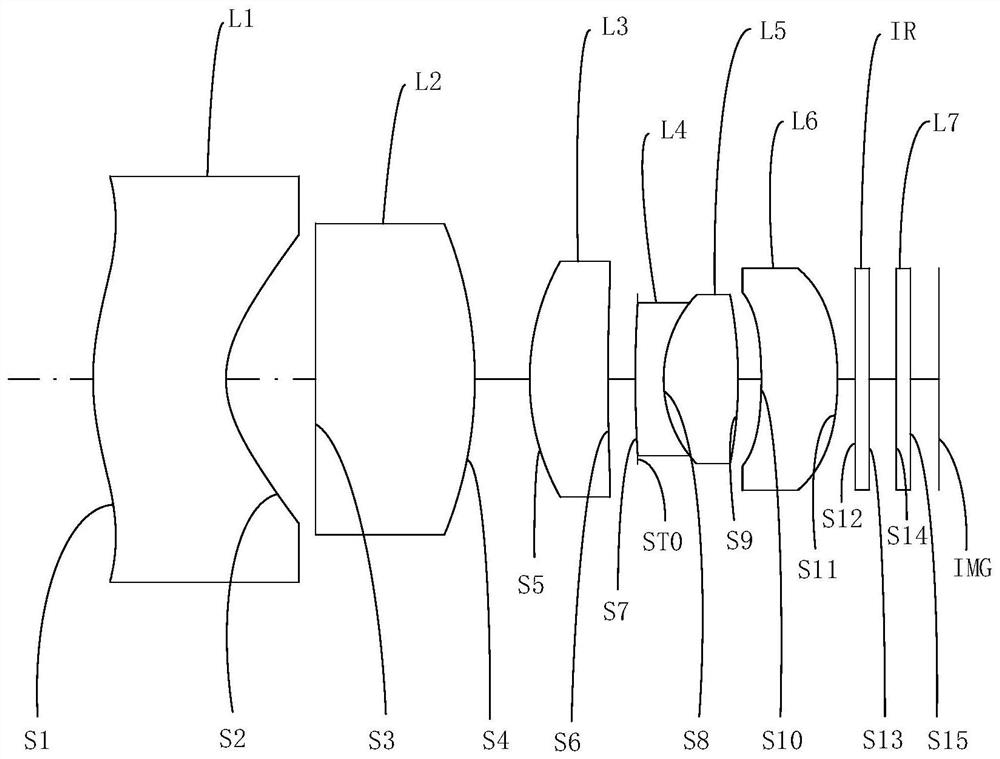

[0074] Please refer to Figure 2a and Figure 2b , the optical system of this embodiment includes in sequence from the object side to the image side along the optical axis direction:

[0075] The first lens L1 has a negative refracting force. The object side S1 of the first lens L1 is convex at the near optical axis and concave at the circumference; the image side S2 of the first lens L1 is concave at the near optical axis and concave at the circumference. place is flat;

[0076] The second lens L2 has a positive refractive power, the object side S3 of the second lens L2 is a plane, and the image side S4 is a convex surface;

[0077] The third lens L3 has a positive refractive power, the object side S5 of the third lens L3 is a convex surface, and the image side S6 is a concave surface;

[0078] The fourth lens L4 has negative refractive power, the object side S7 of the fourth lens L4 is convex, and the image side S8 is concave;

[0079] The fifth lens L5 has a positive re...

no. 3 example

[0090] Please refer to Figure 3a and Figure 3b , the optical system of this embodiment includes in sequence from the object side to the image side along the optical axis direction:

[0091] The first lens L1 has a negative refracting force. The object side S1 of the first lens L1 is convex at the near optical axis and concave at the circumference; the image side S2 of the first lens L1 is concave at the near optical axis and concave at the circumference. place is flat;

[0092] The second lens L2 has a positive refractive power, the object side S3 of the second lens L2 is a plane, and the image side S4 is a convex surface;

[0093] The third lens L3 has a positive refractive power, the object side S5 of the third lens L3 is a convex surface, and the image side S6 is a plane;

[0094] The fourth lens L4 has negative refractive power, the object side S7 of the fourth lens L4 is convex, and the image side S8 is concave;

[0095] The fifth lens L5 has a positive refractive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com