Method for quickly predicting removal rate of spiral curved surface grinding material

A technology for grinding materials and helical surfaces, which is applied in the field of screw grinding and can solve problems such as low efficiency and difficulty in precise control of accuracy consistency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

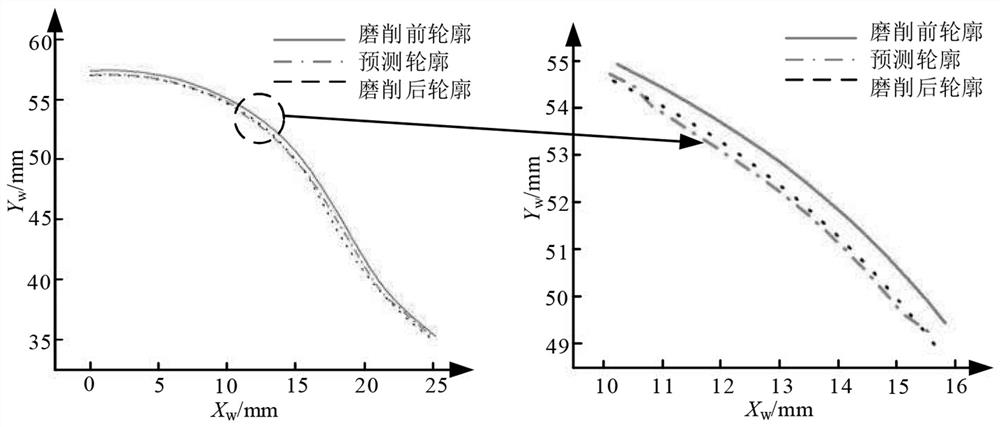

[0065] The method for rapidly predicting the removal rate of grinding materials proposed by the present invention adopts the ThunderGBM regression prediction algorithm to predict the removal rate of grinding materials on the workpiece surface. In the prediction stage, ThunderGBM traverses the prediction tasks and tree models in a parallel computing manner, and calculates the calculation values on each branch, which saves a lot of time and improves computing efficiency compared with traditional CPU operations.

[0066] At the same time, the proposed method of the invention covers the prediction mode of the grinding material removal rate of the two methods of free abrasive belt grinding and contact wheel grinding, and provides an approximate calculation method for the contact stress for the two different contact methods, and as a material Input element for removal rate prediction.

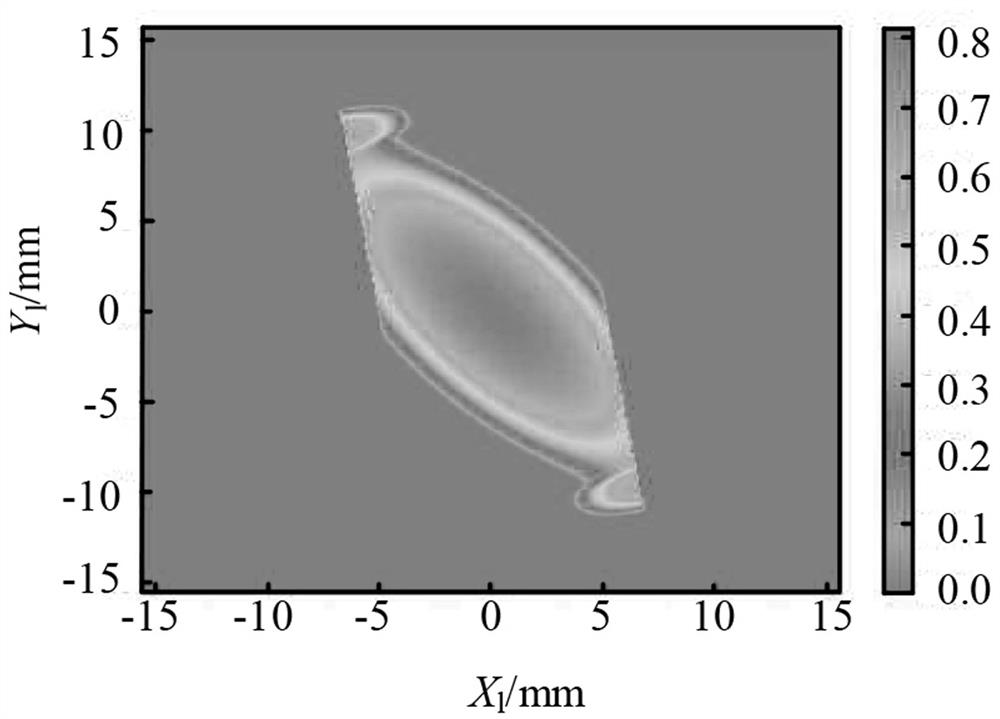

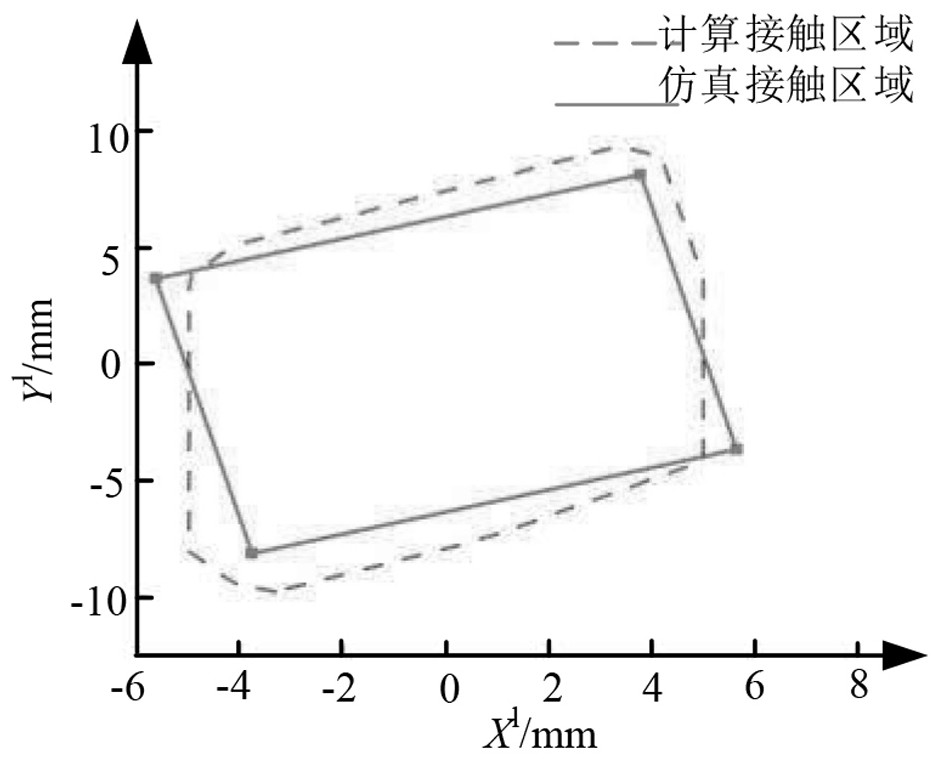

[0067] (1) Semi-analytical contact algorithm for contact wheel grinding

[0068] According to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com