A detection method for unbalanced defect samples based on convolutional neural network

A convolutional neural network and detection method technology, applied in neural learning methods, biological neural network models, neural architectures, etc., can solve problems such as less defect data collected, low proportion of defective products, and inability to model training, and achieve low cost. , Improve the detection performance, the method is simple and easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

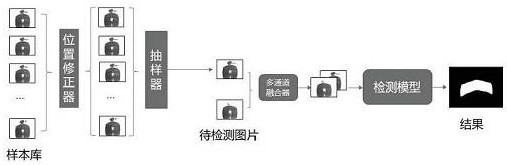

[0039] see figure 1 As shown, a detection method of unbalanced defect samples based on convolutional neural network includes the following steps:

[0040] (1) Pre-collection data: Two types of data need to be collected: one is the original defect data of the product, the technicians determine the possible defect types according to the production situation of the product, and the collectors use photography equipment to collect as much variety as possible according to the defect types The previous data, and make the original image of the training set;

[0041] The second is non-defective data produced in the production environment, which can be collected in large quantities; special attention should be paid to the fact that the environment variables should be completely consistent when collecting the two types of data;

[0042] Specifically, the above-mentioned defect data accounts for 30% of the total data, and the non-defect data accounts for 70% of the total data;

[0043] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com