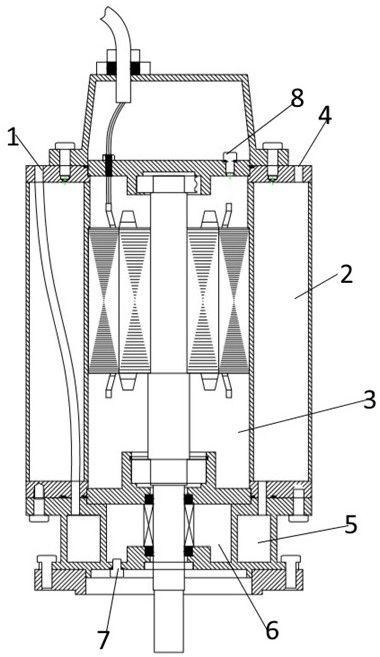

A wet and dry dual-purpose oil-water cooling motor and cooling method thereof

An oil-water cooling, dry and wet dual-use technology, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problem that the optimal required time has not yet been reached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

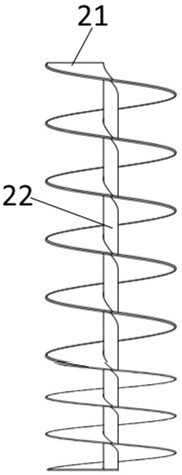

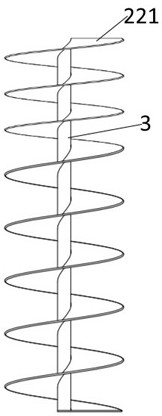

[0034] After the applicant's research and analysis, the reason for this problem (the existing motor cannot work for a long time) is that the current wet and dry motor is only marked with With 90% capacity cooling oil, the heat generated by the motor operation is quickly brought to the casing through the cooling oil, and the heat is dissipated by the cooling ribs. According to the experiment, the motor can run continuously and normally for 1 hour in the air, but it has not yet reached the required optimal time. However, the present invention increases the water circulation chamber without changing the oil cooling chamber, and through the design of the outer water inlet cooling The inner water outlet cooling channel and the inner water outlet cooling channel are used for water cooling of the oil-water cooling motor, and several groups of flushing pipes with the same inclination direction are designed on the inner water outlet cooling channel, and a flow limiting valve is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com