Novel vibrating diaphragm

A new type of peripheral technology, applied in the field of loudspeakers, can solve the problems of insufficient amplitude of the U-shaped track ring and cannot meet the requirements of acoustic effects, and achieve high-amplitude effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

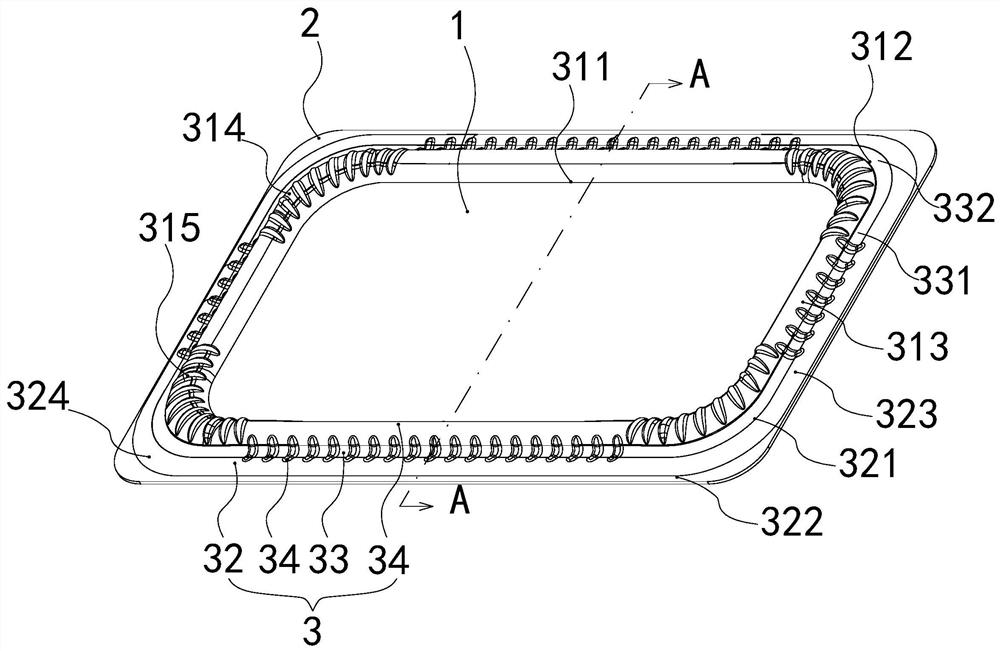

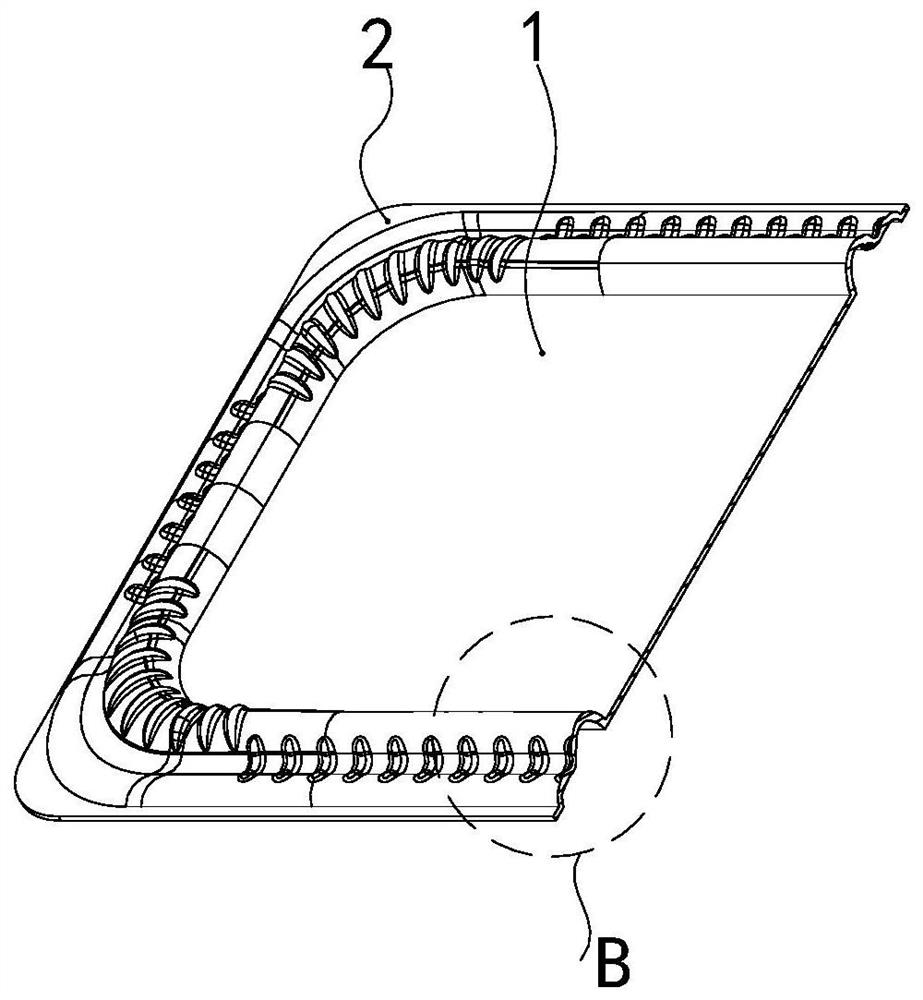

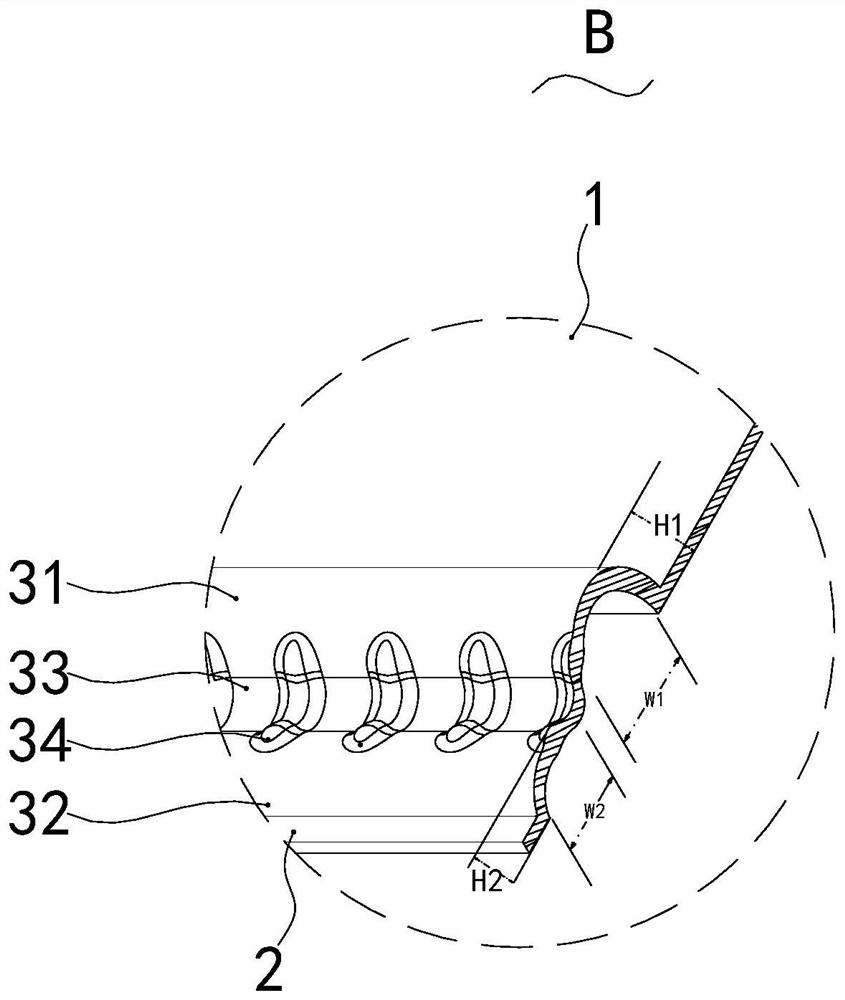

[0021] Such as Figure 1-Figure 3 As shown, a new type of diaphragm has a central part 1, a peripheral part 2 and a ring part 3 connecting the central part 1 and the peripheral part 2. The ring part 3 includes a first ring 31, a second ring 32 and a connection The first ring 31 and the second ring 32 are located at the connecting portion 33 between them, the first ring 31 includes a first edge end 311 connected to the central portion 1 and a second edge end connected to the connecting portion 33 312 ; the second ring 32 includes a first peripheral end 321 connected to the connecting portion 33 and a second peripheral end 322 connected to the peripheral portion 2 ; the first ring 31 and the second ring 32 bulge in the same direction.

[0022] In the basic solution of the present invention, the central part 1 of the diaphragm is generally connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com