Adjusting method of laser display equipment and laser display equipment

A laser display and adjustment method technology, applied in optics, optical components, instruments, etc., can solve the problem of display resolution drop, achieve the effect of solving display resolution drop, increasing drive current, and improving vibration loudness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present application will be described in further detail below in conjunction with the accompanying drawings.

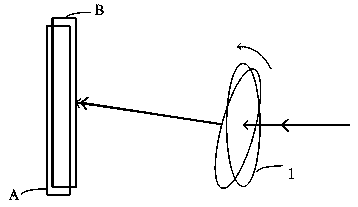

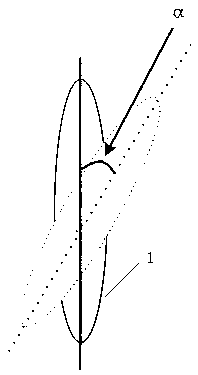

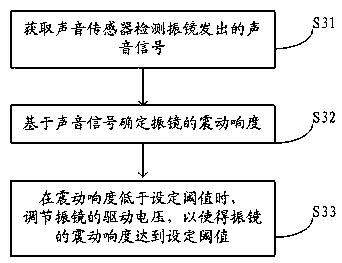

[0019] The adjustment method of the laser display device proposed by this application is based on such as Figure 4 The laser display device shown is realized. The laser display device includes a vibrating mirror 1, a sound sensor 2, a vibration loudness determination module 3 and a vibrating mirror driving module 4; the vibrating mirror driving module 4 is used to drive the vibrating mirror to vibrate according to a set frequency; the sound The sensor 2 is arranged around the vibrating mirror 1 according to a set distance, and is used to detect the sound signal from the vibrating mirror 1; the vibration loudness determination module 3 is used to obtain the sound signal from the vibrating mirror detected by the sound sensor 2, and determine the sound signal of the vibrating mirror based on the sound signal. The vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com