Z-shaped elastic flange structure for ultrasonic transducer and application of Z-shaped elastic flange structure

An ultrasonic transducer and elastic technology, applied in cleaning methods using liquids, fluids using vibration, chemical instruments and methods, etc., can solve problems such as node position deviation, inaccurate setting of flanges, etc. Amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

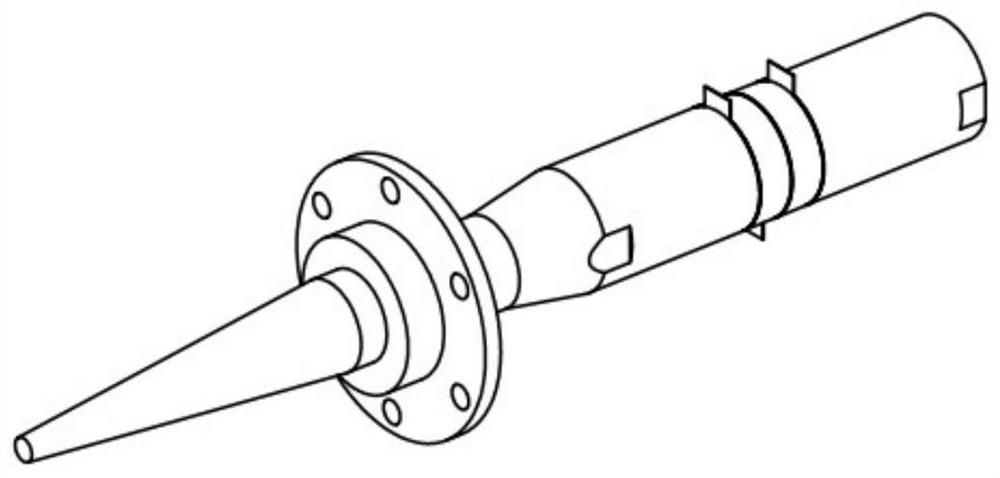

[0039] The modal analysis and calculation are carried out for the ultrasonic transducer with a plane flange at the joint surface and the ultrasonic transducer with a Z-shaped elastic flange structure, and the respective mode shapes within half a cycle around the flange are obtained.

[0040] Such as Figure 6As shown, the modal analysis results of the ultrasonic transducer with a flat flange and the ultrasonic transducer with a Z-shaped elastic flange structure are respectively listed in the upper and lower boxes. The traditional flat flange and the Z-shaped elastic flange The respective positions and postures at three different moments within half a cycle (0.1T ~ 0.5T) of structural vibration. From Figure 6 In (a), it can be seen that when the vibration of the ultrasonic transducer body occurs, the planar flange structure is excited to shrink and expand in the radial direction, such as Figure 6 As shown by the arrow in (a). Due to the rigid fixation of the traditional pl...

Embodiment 2

[0042] The ultrasonic transducer was driven by a sinusoidal electrical signal with a voltage value of 40V, and the amplitude of the ultrasonic transducer was investigated. In order to avoid the impact of ultrasonic transducer heating on its vibration characteristics due to long-term work, each excitation time is only 0.02s. When two ultrasonic transducers with different flange structures are driven by their respective resonant frequencies (corresponding to 40V voltage value), their amplitudes are recorded, as Figure 7 Shown in ① and ②. Considering that the ultrasonic transducer is susceptible to changes in the external environment when it is working, the resonant frequency is also changed accordingly. Therefore, if the actual resonant frequency of the ultrasonic transducer deviates from the applied excitation frequency, the ultrasonic transducer will be detuned. Working in the state, and at the same time, the position of the nodal surface changes to a certain extent, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com