Scalpel rod structure and ultrasonic scalpel including scalpel rod structure

A knife rod and coarse structure technology, applied in the field of ultrasonic scalpel, can solve the problems of endangering the personal safety of patients, affecting the effect of surgery, easy to receive external interference and load effect, etc., and achieve the effect of improving power conversion efficiency and amplitude enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] It should be noted that the embodiments of the present invention and the features in the embodiments can be combined with each other if there is no conflict.

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and in conjunction with the embodiments.

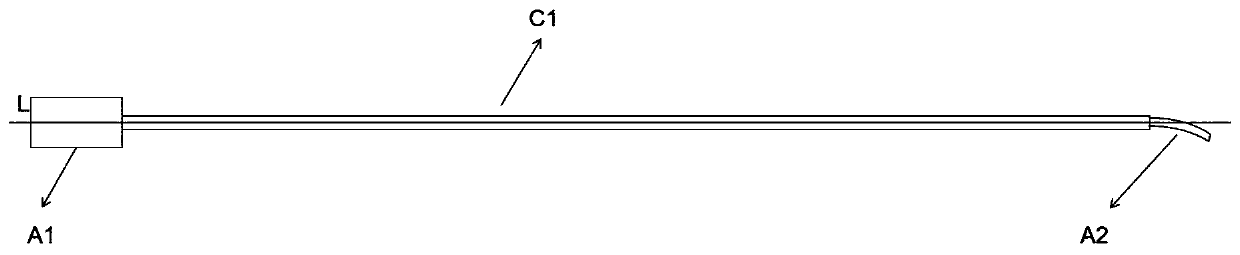

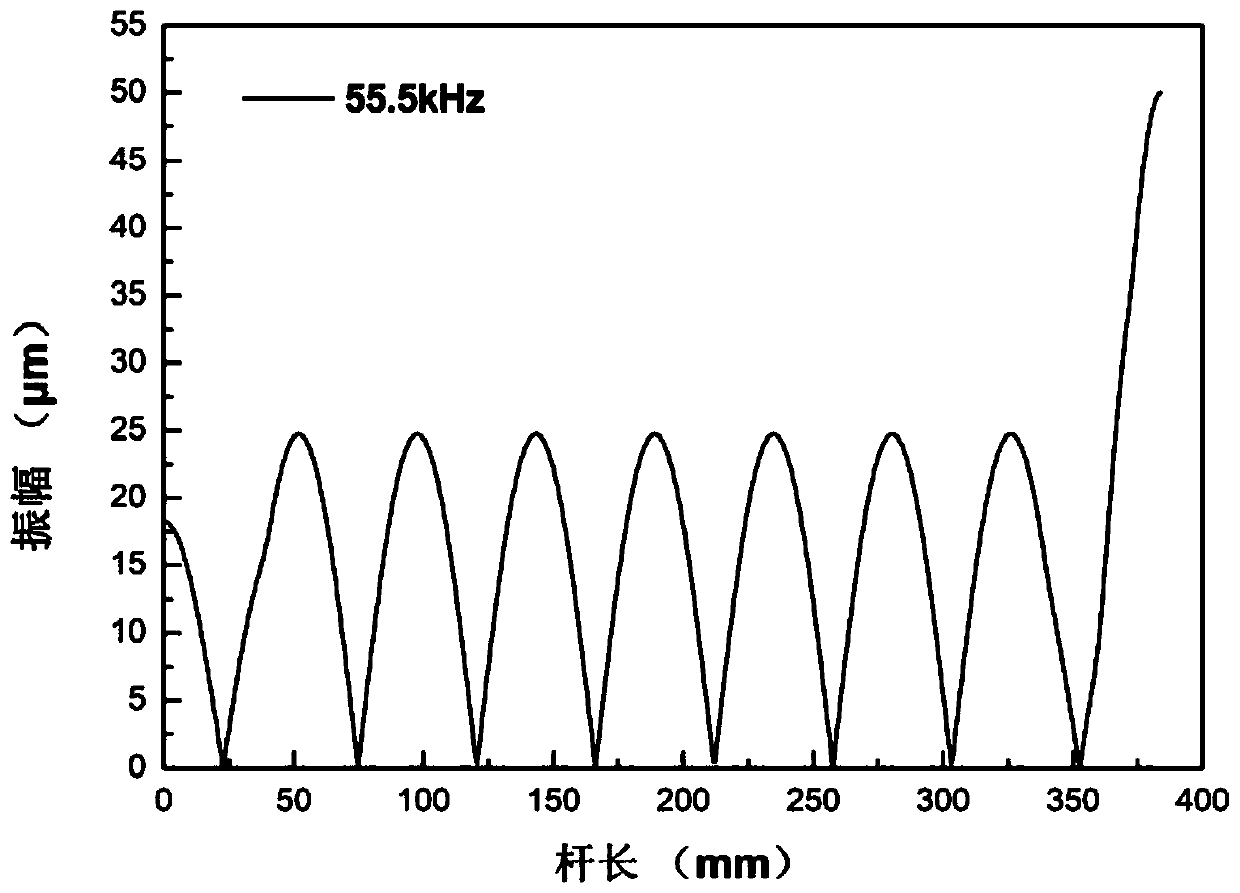

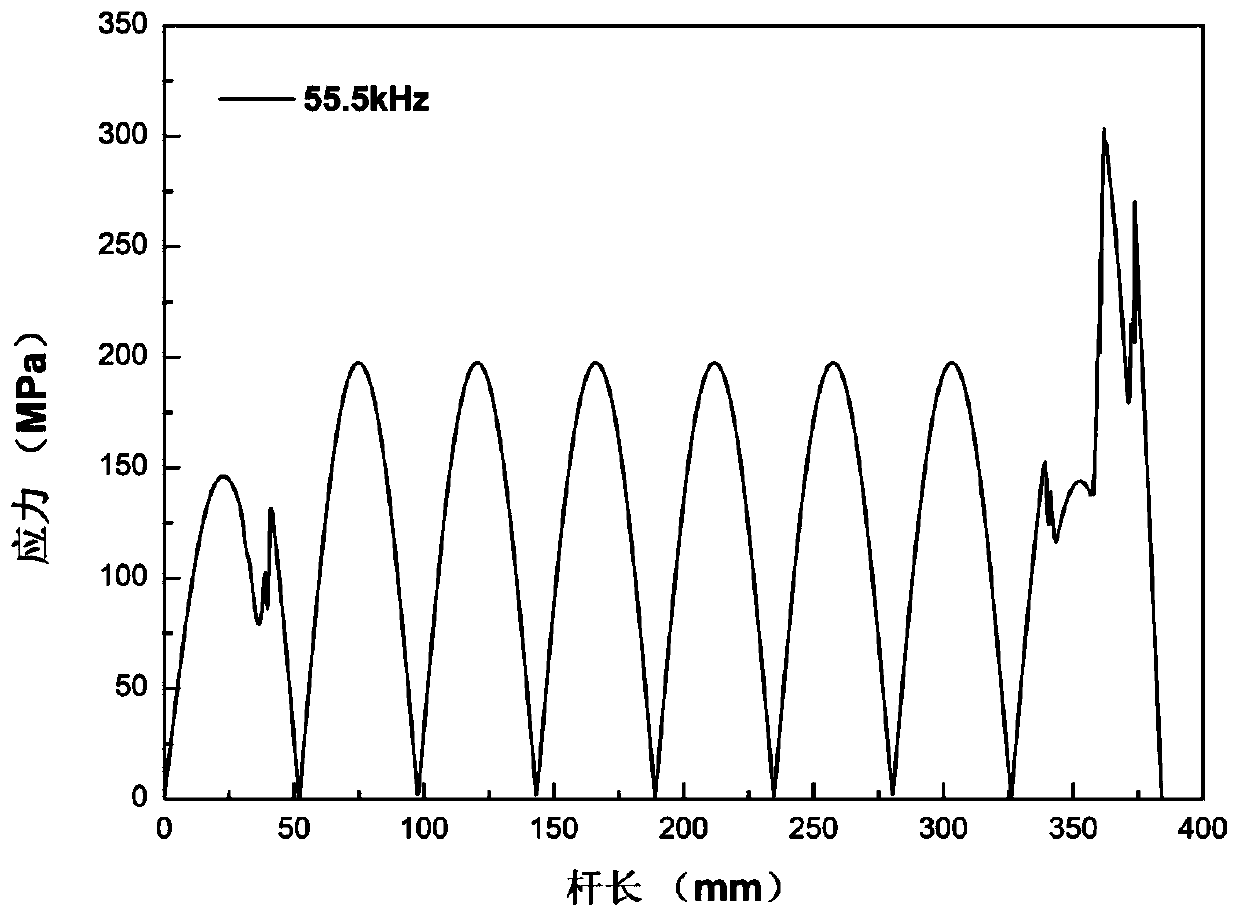

[0026] Such as figure 1 Shown is an existing ultrasonic scalpel, which has a tail, a slender shaft and a blade head. The amplitude diagram and stress diagram of the existing ultrasonic scalpel at a fixed frequency of 55.5kHz are as follows figure 2 with image 3 Shown. The length of the slender shaft of the existing ultrasonic scalpel is 320.7 mm, the length of the tail is 22.8 mm, and the length of the blade is 23.5 mm.

[0027] Such as Figure 4 As shown, an ultrasonic scalpel includes a shank structure and a cutter head A2 with a total length of 367mm, wherein the length of the shank structure is 343.5mm, and the length of the cutter head A2 is 23.5mm. The shank structure in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com