Coaxial cable joint dismounting and mounting tool

A coaxial cable and tool technology, which is applied in the field of coaxial cable joint disassembly and assembly tools, can solve the problems of prolonging the installation and dismantling of coaxial cable joints, difficulty in plugging and unplugging coaxial cable joints, and reducing work efficiency. Significant benefit, low processing cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in combination with the accompanying drawings.

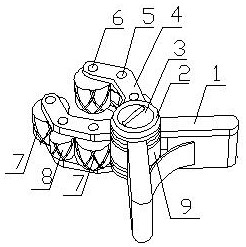

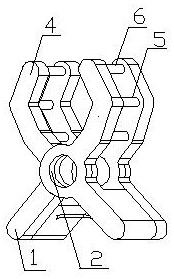

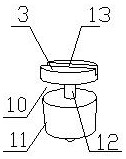

[0015] As shown in the figure, the coaxial cable connector dismounting tool includes a power mechanism, a fixing mechanism, a connecting mechanism, and a transmission mechanism. "shape, the fixing frame is respectively provided with connecting holes 2, the connecting holes are used to place the connection structure, the elastic piece 17 is arranged between the lower part of the fixed frame, the upper part of the fixed frame is provided with an arc-shaped encircling clamping arm 4, and the arc-shaped encircling The upper and lower parts on both sides of the clamping arm are respectively provided with the rotating shaft 6 of the working wheel, and the arc-shaped embracing of the outer position between the rotating shafts of the working wheel is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com